Contact Us

- Ms. Bonnie Zhao

- +86-371-5677 1821

- +86-135-2669-2320

- Skype:bonniezhao2

- oilmachine@doinggroup.com

- Chat Online

Faqs

News

Video

About Us

Pyrolysis Plant Products

General Questions of Pyrolysis Plant

Technical support

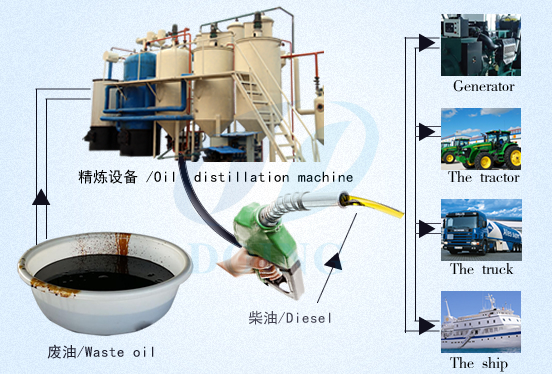

Oil distillation plant definition

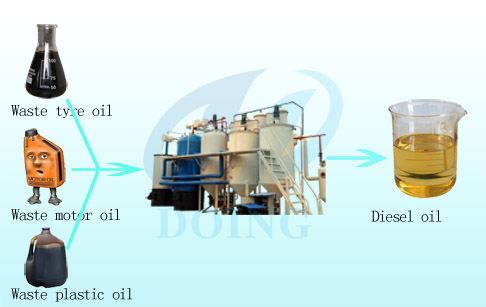

Oil distillation is the chemical engineering processes and other facilities

used in oil refineries to

distills the incoming crude oil, pyrolysis oil and

waste oil into useful products such as diesel oil

and fuel oils, gasoline

or petrol.

Diesel application

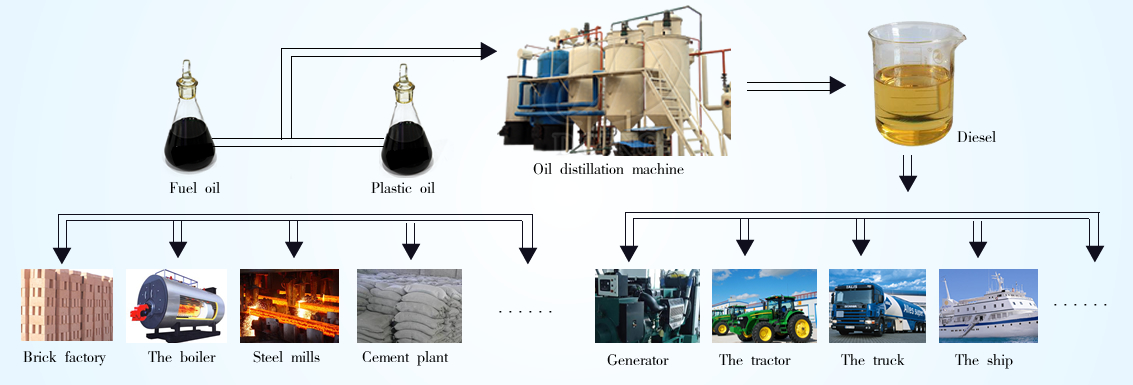

Distillation plant means can purify the dirty waste oil. Distillation plant

can refining waste tyre

oil,plastic oil,black oil,waste engine oil, motor

oil etc.The oil yield rate of waste tire and waste plastic oil is about 85%.

The oil yield rate of waste engine oil is 90% or more.

Technical support

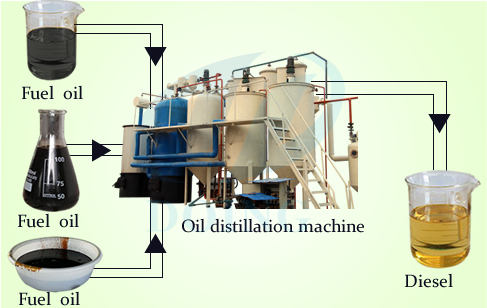

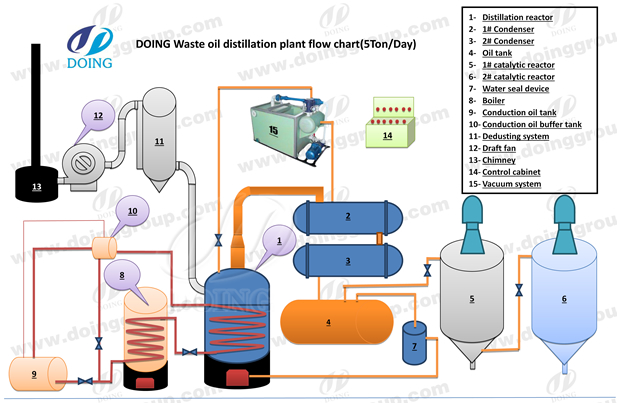

Oil distillation plant working process

Distillation plant adopts the latest technology called refining or

distillation.The distillation plant is efficient

way to save both money

and the environment.The final diesel can be used in

diesel generator, tractors, trucks, agricultural vehicles etc.

- 1.Prepare waste crude oil

- 2.Heating for distillation

- 3.Cooling

- 4.Chemical process for cleaning the distillation oil

- 5.Collect final diesel product

Technical support

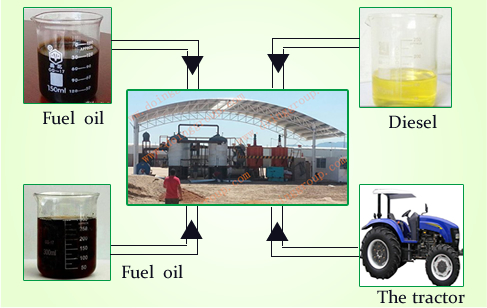

Profit analysis of oil distillaiton plant

Distillation plant can purify waste tire oil, plastic oil, waste engine oil, the final diesel can be used for tractors, trucks, and diesel oil generators, ships etc.

| 5-10T Distillation Plant Profit Analysis | |

| Costs | |

| Heating fuel | Fuel oil: 500kg/day or gas:150m3/day |

| Electricity | 24.5Kw/h |

| Water | No consumption (for recycle use) |

| Chemical catalyst | About USD100/day |

| Workers | 1-2 workers per shift |

| Return | |

| Diesel | 85% output |

| Asphalt | 10% output |