Why we developed the continuous pyrolysis plant?

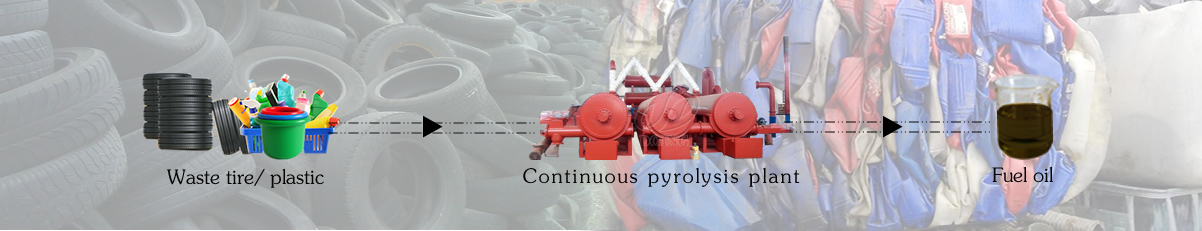

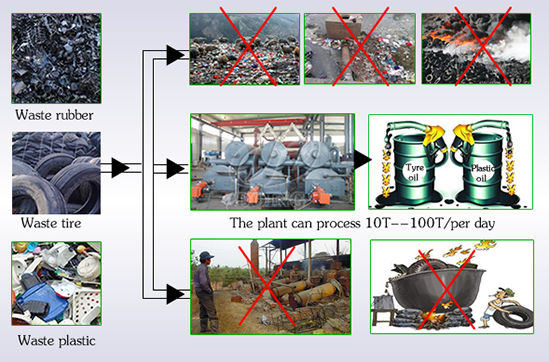

The continuous pyrolysis plant can handle many kinds of waste, such as wasteplastic,waste tyres,waste rubber,oil sludge and so on. Our conitnuous pyrolysis plant is controlled by PLC system with automaticfeeding and discharge system,which only need 1-2 worker for operating the PLCor computer is ok,so it is very easy ti operate it and our customers can save much cost of time and labor. Our continuous pyrolysis plant adapts to multiple reactor design which can makefully pyrolysis of waste tire/plastics,thus to get high oil output. Also due to continuous feeding and discharge system,and unique mutiple reactordedign, our automatic continuous pyrolysis plant can process at least to tons waste tirs per day, up to 100T/D. Form what has been discussed above,That's why we developed the continuouspyrolysis plant.

Oil distillation plant working process

| Oil yield of different raw material | |||

| PE | 95% | Submarine cable | 75% |

| PP | 90% | Rubber cable | 35% |

| PS | 90% | Sole | 30% |

| ABS | 40% | Big tires | 45%~50% |

| Plastic bag | 50% | Small tires | 35%~40% |

| House garbage | 35%~50% | PVC | Not suitable |

| Plastic cable | 80% | PET | Not suitable |

| Leftovers of paper | Wet 15-20%,dry 60% | ||

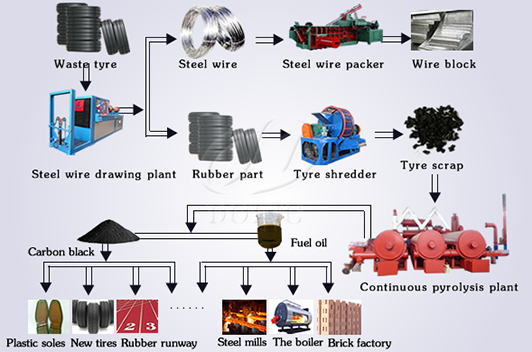

Through continuous improvement and constant technology upgrading,we have designed continuous waste tyre/plastic/rubber.

Pyrolysis plant which can convert tyre/plastic/rubber into useful resources more efficiently.

Continuous pyrolysis can process raw material:waste tire,waste plastic and waste rubber.

How does continuous pyrolysis plant works?

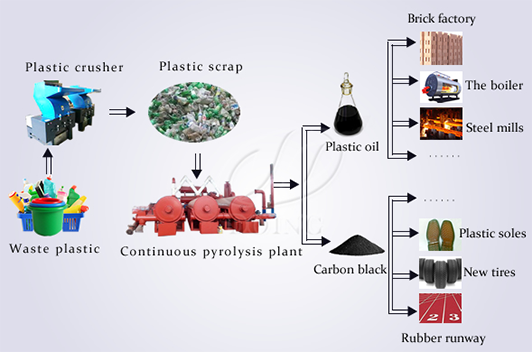

1.All available plastic can boe shredded by plastics, and then feed plastic granules directly into plastic continuous pyrolysis plant through the feeding door.

2.Our feeding door is with screw inside, so it can help you easily convey the plastic granules into our reactor No 1,then all the plastic can be decomposed under the high temperature through reactor No 1 to reactor No 2, then to reactor No 3...Until all the plastic fully pyrolysed,then all the carbon black powder will be discharged automatically to the carbon black tank.

3.All the available oil gas will be cooled by circulation waste and the extra pyrolysis gas will be recycled through pipes into the burners for heating again. In our continuous waste plastic pyrolysis plant,the water circulation system and extra pyrolysis gas recycling system will help you save much fuel and waste resource, in this way, our plastic continuous pyrolysis plant can minimize your cost and maximize your profits.

Waste plastics processing

1.All available plastic can boe shredded by plastics, and then feed plastic granules directly into plastic continuous pyrolysis plant through the feeding door.

2.Our feeding door is with screw inside, so it can help you easily convey the plastic granules into our reactor No 1,then all the plastic can be decomposed under the high temperature through reactor No 1 to reactor No 2, then to reactor No 3...Until all the plastic fully pyrolysed,then all the carbon black powder will be discharged automatically to the carbon black tank.

3.All the available oil gas will be cooled by circulation waste and the extra pyrolysis gas will be recycled through pipes into the burners for heating again. In our continuous waste plastic pyrolysis plant,the water circulation system and extra pyrolysis gas recycling system will help you save much fuel and waste resource, in this way, our plastic continuous pyrolysis plant can minimize your cost and maximize your profits.

Oil distillation plant working process

| ROI analysis of 10T continuous waste plastic pyrolysis plant | |||

| cost | |||

| Waste plastic | according to market | ||

| Heating fuel | 300kg fuel oil or 100m3 gas for start up | ||

| Electricity | 25Kw/h | ||

| Water | Water is for recycle use, no consumption | ||

| Labour | 1 workers per shift | ||

| Return/day | |||

| Fuel oil | 7000-7500 liters | ||

| Carbon black | 2-2.5 tons | ||

| Tail gas | For recycle use | ||

Leave Your Message