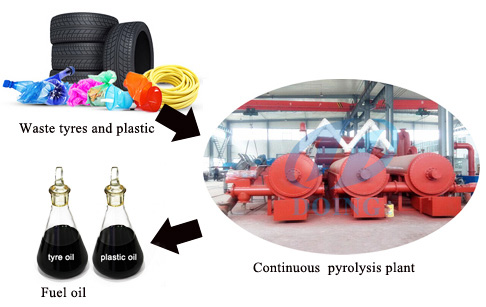

Fully automatic tyre & plastic pyrolysis plant

Fully automatic tyre & plastic pyrolysis plant

1. suitable raw materials: PE,PP,PS plasticmaterials,waste tyre, leftovers of paper,house garbage, plastic cable, plastic bag,submarine cable, sole and so on.

2. structures: combine the static outside reactor with dynamic inside reactor; automatic continuous feeding in, deslagging, control intelligent.

3. working form: continuous, keeping on feeding in, deslagging, outputting oil without stopping.

4. heating method: heating outside and inside at the same time, twice to three times faster than the ordinary heating.

The following heating fuels can be used: coal gas, natural gas, oil, coal\wood, electric and so on. Both long-distance heating and reflect heating are ok.

| Raw material | PE,PP,PS plasticmaterials,waste tyre, leftovers of paper,house garbage, plastic cable, plastic bag,submarine cable, sole |

| Capacity | 6T, 8T, 10T,20T,100T |

| Working pressure | Ordinary pressure |

| Cooling ways | Water |

| Operation type | fully automatic continuous |

| Heating means | Hot blow, flammable, gas, coal, oil, wood, electric |

| NO | Name | Percentage | Usage | |

| 1 | Tyre fuel oil |

|

45% |

1.Can be sold directly 2.Can be as fuel 3.Can be used industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic factory. |

| 2 | Carbon black |

|

30% |

1.Can be sold directly 2.Can be used electric cable jacketing,black nylon bag,rubber additive |

| 3 | Steel wire |

|

15% |

1.Can be sold directly 2.Make steel bloom by use hydraulic press-packing |

| 4 | Oil gas |

|

10% |

1.Can be as fuel burn by use gas burning system 2.Extra gas also be storage as fuel for other heating |

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?