Plastic to diesel process plant cost

Plastic waste is a growing concern and the drivers behind it look set to continue. Although recently there has been a slight decrease in plastic production, this is unlikely to be maintained.Plastic is a highly useful material and its applications are expected to increase as more new products and plastics are developed to meet demands.The increased use and production of plastic in developing and emerging countries is a particular concern, as the sophistication of their waste management infrastructure may not be developing at an appropriate rate to deal with their increasing levels of plastic waste.

Waste plastic water pollution

Say no to waste plastic and turn it into energy

Some other issues with waste plastic are that it affects humans, animals and marine life; it causes soil infertility where dumped; and only 8% of all plastic waste is recycled! Sounds a trifle, right! Another lesser known factual reality is that for the production of plastic, 7% of the global crude oil is consumed, which is more than China's total crude oil consumption.

So what do we do with these ever-growing mounds of plastic waste? Bury plastic underground? Burn it? Or launch it into space! These solutions are more disastrous than the problem itself.

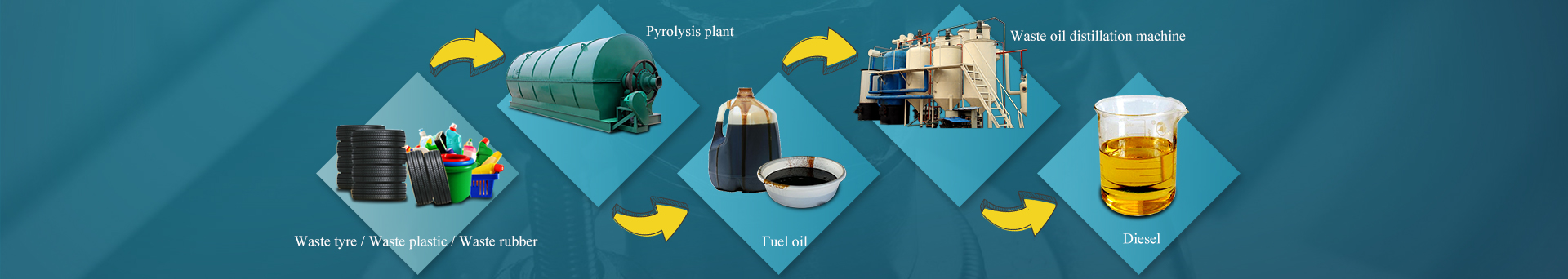

That’s why we developed the Plastic to diesel process plant. This whole process include a pyrolysis process and a distillation process.

Plastic to diesel process plant

In fact, the plastic to diesel process is not a step to achieve. We need to use the pyrolysis technology and oil distillation technology. The first step we get plastic pyrolysis oil by using the waste plastic pyrolysis plant. The second step, with the help of one set of plastic to diesel process plant , the plastic oil can be further refined into diesel .

1. Shredding or compressing for better feeding

Firstly, the waste material must be segregated and, if possible, be cleaned. Then it is shredded to speed up the reaction and to ensure that the reaction is complete.

2. Anaerobic heating

The shredded material must be heated in a controlled manner in an oxygen-free reactor. One of the most crucial factors in this operation is maintaining the right temperature(~430C for plastic) and the rate of heating, as they define the quality and the quantity of the final product.

3. Condensation

The gas that comes out from the reactor must be condensed by passing it through a condensation system, which the recycled water cooling system is the most commonly used method at present.

Waste plastic pyrolysis plant

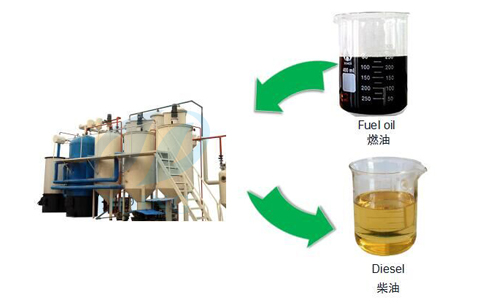

The crude oil product that you obtain from the plastic to diesel process plnat can be used as furnace oil but it isn't sufficiently pure for engines. If you want to use it as engine fuel, you need to extract and purify the desired products from the crude oil through a fractional distillation process.

And below are the normal distillation process:

1.Pump the crude pyrolysis oil to the distillation reactor

2.Heating

3.Condensation

4.Chemical processing

Waste plastic to diesel process plant

| Prepared by Plastic to diesel process plant cost | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area |

35m*15m |

|

| Technical parameter of Plastic to diesel process plant cost | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | dity motor oil, waste tire crude oil, plastic oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

And the diesel fuel can be used in the low speed engine, such as digging machine, road roller, loading machine and so on. The diesel has higher economic value and higher price in the market, and also can relieve energy crisis.

Diesel application

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia

-

15 TPD used tyre pyrolysis machine produced fuel oil in Brazil

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?