Crude oil to diesel refinery distillaion process plant

Crude oil to diesel refinery distillaion process plant

Crude oil to diesel refinery distillaion process plant

Crude oil to diesel refinery distillaion process plant

By using the heat transfer heating system, our client can save much fuel to heat the whole reactor, and the heating speed is faster and the temperature can keep the reactor hot for longer time,so the whole process is faster with less fuel

2: The heating circulation system is more environmental

All the heat transfer system is a circulating system, the heat transfer oil is recycling inside the reactor. So in total, you can fire less fuel, which not only save your cost on fuel also it is more environmental-friendly. All the system is sealed, in the terms of smoke and smell, our new design Used oil refining plant workers better.

3:The vertical reactor

From our design,It is very easy to clean the slag , it will be down through the bottom of the vertical reactors. So the operation is easier

4: Continuously working

When operating the machine,first you pump oil inside the reactor to heat,after finishing heating,it will becoming oil gas and goes to cooling system,then go to another tank.So,the first reactor is empty,no need to stop,you could pump another tank of oil again into the first tank ,continuously working.

| Technical parameter of Crude oil to diesel refinery distillaion process plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

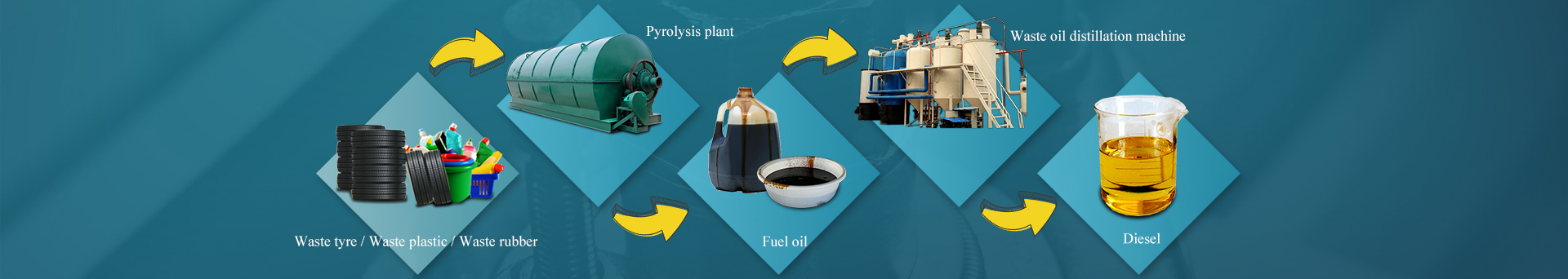

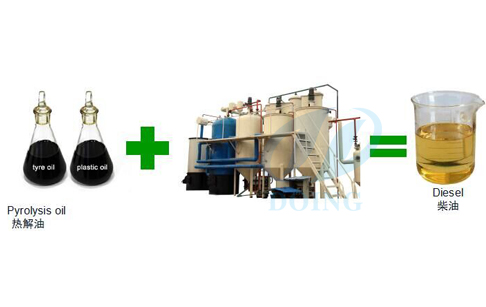

| Raw material | crude oil,tyre oil, plastic oil, used motor oil,black engine oil, lube oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?