Refining used motor oil into diesel

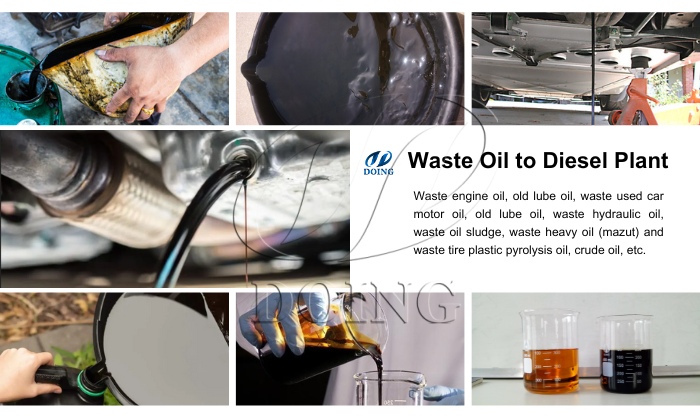

Used motor oil that can be used in used motor oil distillation machine

Used motor oil that can be used in used motor oil distillation machine

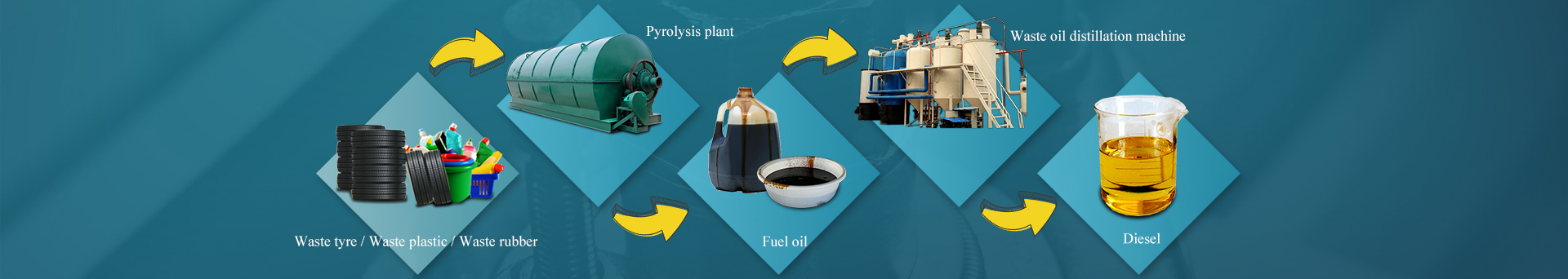

With the improvement of living standards, the car has become a necessary transportation tool for us to travel. The usual disposal method for the large amount of waste engine oil that is replaced every year from the car is to dump it directly. This way of treating waste oil will not only cause soil pollution, it will also be a serious waste. In order to avoid the waste, DOING developed the technology to refine the used motor oil into diesel. It is a method of using high temperature distillation chemistry to further refine the used motor oil, and then get clean diesel oil.

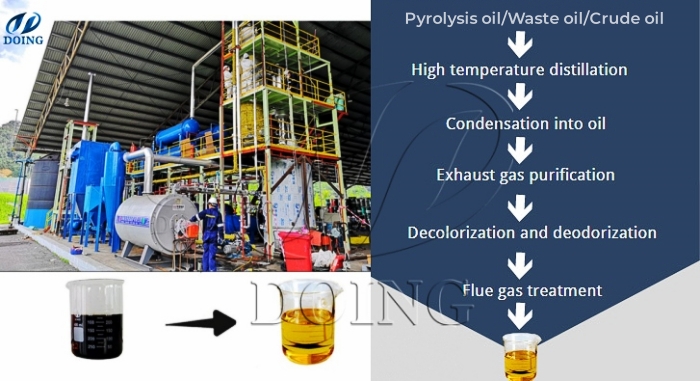

The specific operating procedure for refining used motor oil into diesel oil is as follows:

1. The used motor oil is poured into the reactor and heated and distilled.

2. When the temperature rises to a certain extent, the impurities in the used motor oil will be distilled off, the oil and gas will rise, and the impurities will fall into the bottom of the distillation reactor.

3. The oil gas generated enters the condensing system and is cooled into liquid oil and falls into the oil tank.

Working process for refining used motor oil into diesel

Working process for refining used motor oil into diesel

4. The liquid oil obtained is deodored and decolored, then the final product is non-standard diesel oil.

5. Impurities produced during distillation process will eventually be discharged outside from the reactor automatically.

Through refining used motor oil into diesel process we can finally get diesel and asphalt. Due to its wide range of uses in the market, huge profits can be obtained after sales. The specific profit analysis is as follows(Take DOING 5TPD used motor oil refining to diesel distillation machine as an example):

Operating costs

Used motor oil: 10 tons X288 dollars / ton = 2868 dollars

Heating the fuel can use any of the following:

1) Coal: 0.4 tons X 64 dollars/ton = 25 dollars

2) Fuel: 0.6 tons x 478 dollars/ton = 287 dollars

3) Diesel: 0.5 ton X 765 dollars/ton = 382 dollars

4) Natural gas: 200m³ X 0.36USD / m³ = 72 dollars

Power consumption: 25KW / h X 0.16USD X 20h = 80h

Water consumption: water resources can be recycled, almost no consumption

Workers: 1-2 people X 16 dollars = 32 dollars

DOING used motor oil distillation machine for sale

Earnings/day

Fuel: 8 tons X 765 dollars/ton = 6118 dollars

Asphalt: 1.5 tons X 175USD/ton = 263 dollars

Profit/day (calculated on fuel diesel) : 3017 dollars

If you think that the profit from the refinement of used motor oil into diesel is not enough to meet the needs of your investment, don't worry, we also have a diesel deep purification system that can be used as an option, usually under standard refining systems. Diesel is already very clean, but if you want to get a better color of diesel, we can also provide a deep purification system, in the end you can get much lighter diesel products.

Applications of obtained diesel oil

Applications of obtained diesel oil

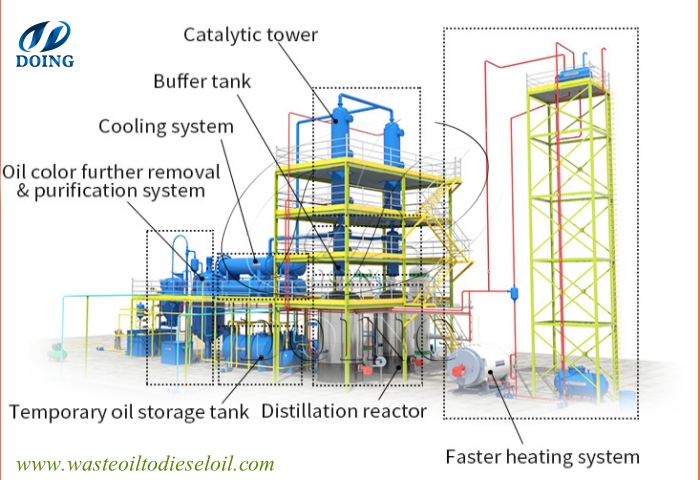

Our main advantages of refining used motor oil into diesel are as follows:

1. Spiral coil heating system makes the heating more uniform.

2. Double heating system, fast heating, short time.

3. Vertical reactor design for automatic slagging.

4. Fully continuous equipment, simple operation, moderate investment.

3D display of DOING latest used motor oil distillation machine

3D display of DOING latest used motor oil distillation machine

Refining used motor oil into diesel Technical parameter

| Technical parameter of refining used motor oil into diesel | |

| Items | Contents |

| Model | DY-D-0.1-14TPD |

| Raw material | Used motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

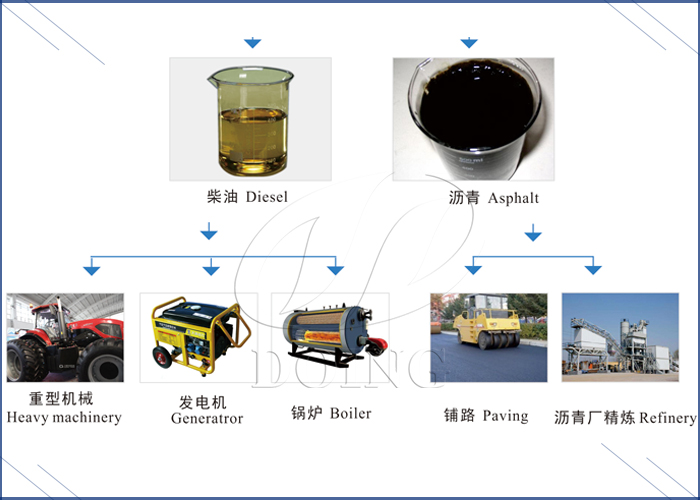

After used motor oil was refined, and we can finally get 80-85% diesel and 10-15% bitumen analogue. These final products are also the sources of profits mentioned above. What specific uses of these end products?

1. Diesel oil: Mainly used for heavy machinery, generator power oil, or boiler heating fuel.

Uses of obtained diesel and asphalt

Uses of obtained diesel and asphalt

2. Asphalt: Mainly used for paving, or sent to asphalt refineries.

With the increase of the global energy crisis, refining used motor oil into diesel will be an inevitable trend, and the current market prospects are very good. It is your best choice for investment!

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?