What equipment can be used to distill pyrolysis tyre derived oil?

For pyrolysis tyre derived oil, it can be used in some heavy oil industries, such as cement factories, steel factories, glass factories, boiler heating, heavy oil generators, etc. But if you want to distill pyrolysis tyre derived oil, waste oil recycling plant will be a better method, which can distill pyrolysis tyre derived oil to diesel in an environmentally friendly method.

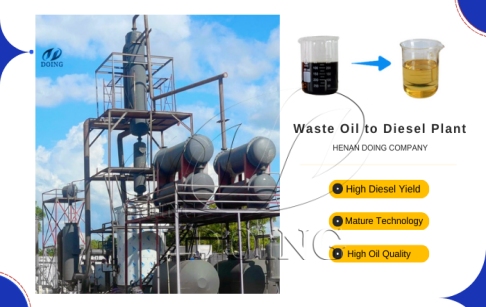

DOING waste oil recycling plant for sale

DOING waste oil recycling plant for sale

As a leading manufacturer and supplier of waste recycling environmental protection equipment in the industry, DOING can provide waste oil recycling plant to distill pyrolysis tyre derived oil to diesel oil, which has high yield and low consumption. The obtained diesel oil is a good alternative fuel that can be used in heavy machinery, generators, boiler heating, trucks, ships, etc.Then let's have a brief learning about the process of distilling pyrolysis tyre derived oil:

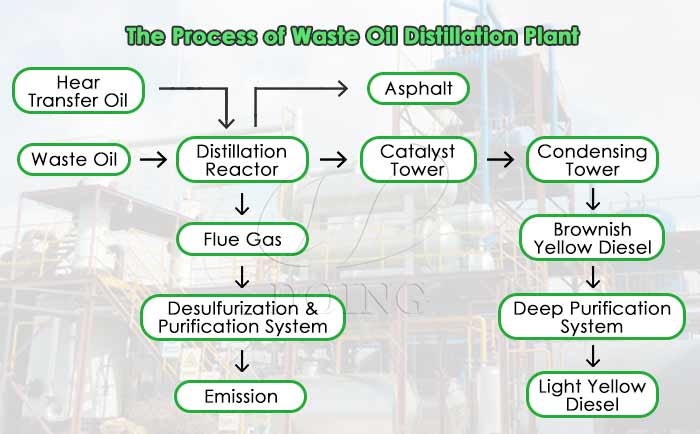

For its process can be divided into several parts:

1. Pre-heating system

Heating boiler as one of the optional configurations of DOING waste oil recycling plant, if the customer wants to improve its heating efficiency, it is recommended to use this device to shorten its heating time. Compared with the common design in the market, whose furnace can be completed in 2-3 days, the entire distill process of DOING waste oil recycling plant can be completed in 20-22 hours.

2. Distillation reactor

The distillation reactor used in DOING waste oil recycling plant is the vertical design, which is different from the horizontal design of the common design in the market. The common design waste oil recycling plant has low heating efficiency and is very inconvenient to discharge asphalt. The design of DOING waste oil recycling plant can realize asphalt automatic discharging, which is convenient and quick.

Work process of DOING waste oil recycling plant

Work process of DOING waste oil recycling plant

3. Catalytic system

To meet the various demands of customers and enhance work convenience, DOING also researched the new catalytic tower design waste oil recycling plant, using a recyclable solid catalyst method, which has a long service life and does not require the replacement of the catalyst in each furnace. And the solid catalyst is researched by DOING engineers, which can be purchased from DOING directly.

4. Condensation system

DOING waste oil recycling plant adopts horizontal condenser design to increase the oil-gas contact area, improve the cooling effect and increase the oil yield.

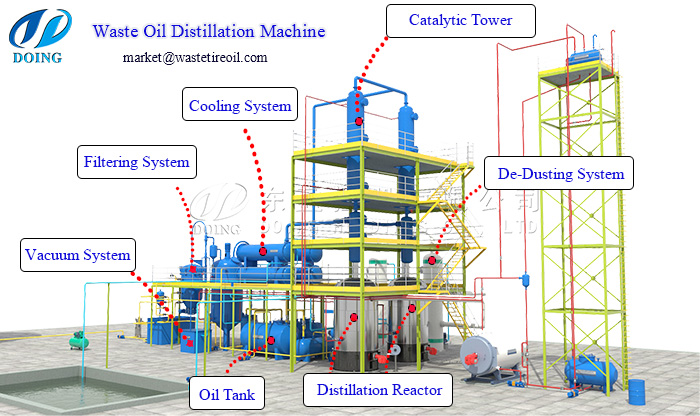

Detailed configurations of DOING waste oil recycling plant

Detailed configurations of DOING waste oil recycling plant

5. Further purification filter system

This step is served as another option for DOING waste oil recycling plant, with the aim of further improving its oil product. According to the real feedback of our Ghanadian customer, after distillation and further filtration, the oil is very clear and bright, even similar to gasoline.

Therefore, if you want to distill pyrolysis tyre derived oil, waste oil recycling plant will be the best method. For more information about DOING waste oil recycling plants, welcome to contact us directly, our sales manager can share more equipment design details and project cases for you.

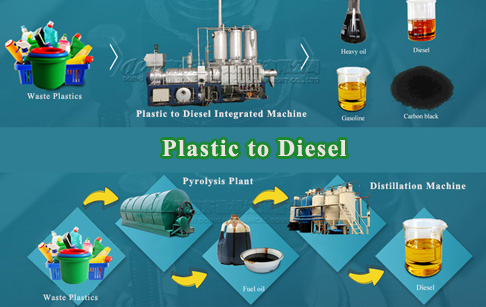

PREV:Can plastic be converted back to oil? How to make fuel oil from waste plastic?

PREV:Can plastic be converted back to oil? How to make fuel oil from waste plastic?

NEXT:What is the profit margin of the waste oil recycling distillation industry?

NEXT:What is the profit margin of the waste oil recycling distillation industry?

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Waste tire to diesel plant project installed in South Africa

-

8 sets of 15 ton plastic to oil pyrolysis machines installed in China

-

Waste tire pyrolysis machine and waste oil distillation machine were successfully installed in Japan

-

A set of 7TPD waste oil to diesel distillation machine was installed in Mali

-

8 sets of waste oil sludge pyrolysis machines put into operation in China

-

-

14 tons/day waste oil to diesel distillation plant installed in Indonesia