Contact Us

- Ms. Bonnie Zhao

- +86-371-5677 1821

- +86 158 9380 0169

- Skype:bonniezhao2

- oilmachine@doinggroup.com

- Chat Online

Hot selling products

New products

Faqs

Why we developed the continuous waste tire pyrolysis plant?

How about the business of continuous waste plastic/tyre pyrolysis plant?

What is the advantage of continuous waste tyre pyrolysis plant?

What is difference of batch waste tire pyrolysis plant and continuous waste tire pyrolysis plant

What the advantage of continuous tyre pyrolysis plant ?

What is difference of continuous pyrolysis plant and batch pyrolysis plant?

What is continuous automatic plastic into oil machine?

Why recycling waste plastic is important ?

How to recycle waste tyre by waste tyre pyrolysis plant ?

What's profit analysis of distillaiton plant?

What is distillation ?

What about distillation machine FAQ?

What kinds of waste oil does distillation machine can refining?

How to refining used oil to diesel?

How to make diesel fuel from 10 ton tyres oil distillation machine and its output?

How to turning tyres into diesel fuel?

What is diesel oil used for?

What is the application of final products of oil distillation machine?

What is the flow of Carbon black pellet Production Line?

When do we need using Circle cutting machine?

Why we need hydraulic cutting machine?

What is the function of Carbon black Lifting Machine?

What is the differences between hydraulic cutting machine and circle cutting machine?

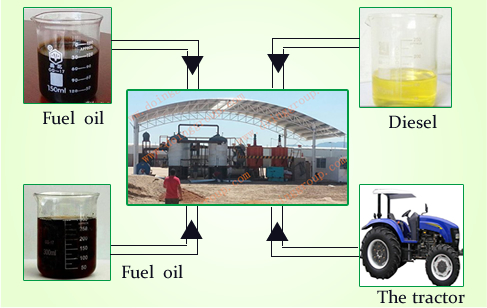

Refined tyre oil can be directly used in tractor

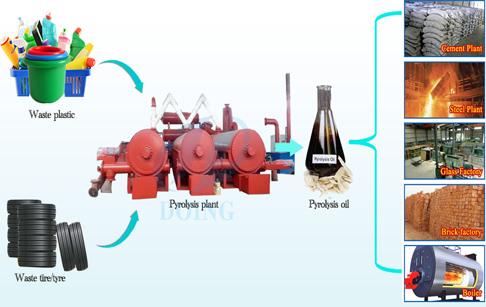

Pyrolysis Plant Products

Pyrolysis process flow chart

What is the advantage of continuous waste tyre pyrolysis plant?

- 2016-11-25 14:19

- FAQ of Pyrolysis Plant

- Chat Online

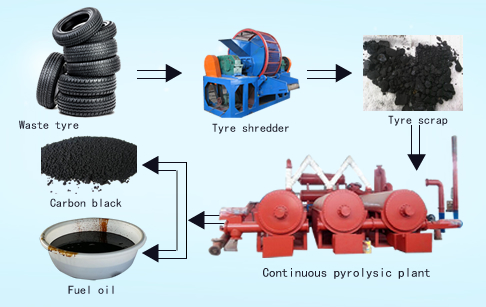

Continuous waste tyre pyrolysis plant

Our continuous waste tyre pyrolysis plant adopts mutiple reactor design which can make fully pyrolysis of waste tyres, thus to get high oil output.

1.Fully automatic with low labour cost

Our conitnuous waste tyre pyrolysis plant is controled by PLC system with automatic feeding and discharge system, which only need 1-2 worker for operating the PLC or computer is ok.

2.Fully pyrolysis for high oil output

Our continuous waste tyre pyrolysis plant adopts mutiple reactor design which can make fully pyrolysis of waste tires, thus to get high oil output.

3.Big capacity

Also due to continuous feeding and discharge system, and unique mutiple reactor design, our fully automatic continuous waste tyre pyrolysis plant can process at least 10 tons waste tires per day, up to 100T/D.

4.Internal rotating for conitnuous operation

For external rotating system, you have to change the sealing material every three days, thus cannot achieve the real sense of continuous process. But our continuous waste tyre pyrolysis reactor adopts internal rotating method, which no need to worry about the sealing of the external rotating system.

5.Continuous working save time and energy

6.Long working life

During the continuous pyrolysis process, reactor heating is by indirect hot air heating, which will not damage reactor so much, thus to keep long usage life of the reactors. And since the hard steel wire already removed from waste tires before pyrolysis processs, thus no damage for the reactor.

- Previous:Why we developed the continuous waste tire pyrolysis plant?

- Next:What is difference of batch waste tire pyrolysis plant and continuous waste tire pyrolysis plant