How does continuous waste tyre pyrolysis plant works?

Continuous waste tyre pyrolysis plant

How does continuous waste tyre pyrolysis plant works?

Cotinuous waste tyre pyrolysis plant workis process

2. Remove steel wire: Use a steel wire pulling machine to pull out the steel wire from waste tires. The steel wire pulling machine is operated automatically, which only need one work for operation.

3. Shred tires: Use a specialized tire shredder to process big whole tires into 3-5cm small pieces for easy feeding. The tire shredder is a single and fully automatic shredding system, which can be directly connected to the feeding system of the continuous pyrolysis plant, which no need any transfer process.

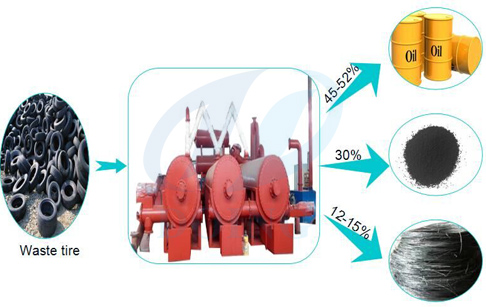

4. Continuous pyrolysis process: Shredded tyres go into the continuous waste tyre pyrolysis plant , will firstly go through a mutiple pyrolysis reactor system to be pyrolyzed into oil gas. And oil gas will be cooling down to liquid oil through the cooling system. The residues (carbon black) will be pushed by continuous feeding tires to the carbon black dischrge system for discharge.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

contact us

Product

project case

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated