Mexican customer's waste pyrolysis distillation plant were successfully installed

In April 2020, Henan Doing assisted customers in installing a 12TPD pyrolysis plant and a 10TPD waste oil distillation plant in Mexico. Mexican customers purchased waste pyrolysis plant mainly to deal with local waste tires and plastics, and then use waste oil distillation plant to refine the tire oil and plastic oil obtained to produce non-standard diesel.

The building of the entire waste tire plastic to diesel recycling project can be divided into two stages, namely: production and delivery stage, installation and commissioning stage:

1.Production and delivery stage picture

Waste pyrolysis distillation plant delivered to Mexico

Waste pyrolysis distillation plant delivered to Mexico

【Services provided by DOING】

•Demand analysis: First, Doing's sales manager communicated in depth with Mexican customers to understand their specific needs for processing waste tire and plastic, production scale, site conditions and budget constraints.

•Scheme design: Based on demand analysis, Doing's technical team developed personalized equipment solutions, including the flow charts, plant designs, etc., and provide detailed equipment specifications of waste tire plastic pyrolysis distillation plant.

•Scheme confirmation and optimization: Review the solution with the customer, make necessary adjustments based on feedback, and ensure that the solution meets customer needs.

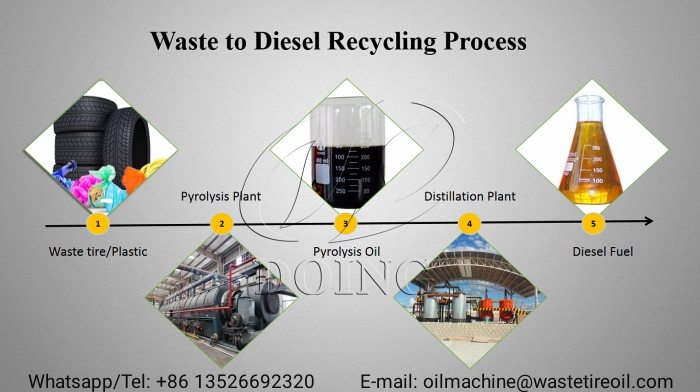

Waste tire plastic to diesel recycling process

Waste tire plastic to diesel recycling process

•Manufacturing: After the solution was confirmed, enter the production stage. We used advanced manufacturing technology and strict quality control systems to ensure the quality of the equipment.

•Factory inspection: All equipment must pass functional tests and safety tests before leaving the factory to ensure that the equipment performance is stable and meets the standards.

•Logistics arrangement: Arrange the most suitable transportation method (sea transportation) according to the size, weight and destination of the equipment, and be responsible for all logistics coordination work.

2. Installation stage and commissioning stage pictures

Waste tire plastic pyrolysis plant project in Mexico

Waste tire plastic pyrolysis plant project in Mexico

Waste pyrolysis oil to diesel distillation plant in Mexico

Waste pyrolysis oil to diesel distillation plant in Mexico

【Services provided by DOING】

• On-site installation: Send professional engineers to the customer's site to assemble and install the waste tire plastic pyrolysis plant and waste oil distillation plant to ensure that the equipment is stable and meets the installation specifications.

• System commissioning: After the installation is completed, conduct comprehensive system commissioning, including single-machine testing and whole-line linkage testing, to ensure smooth operation of the equipment.

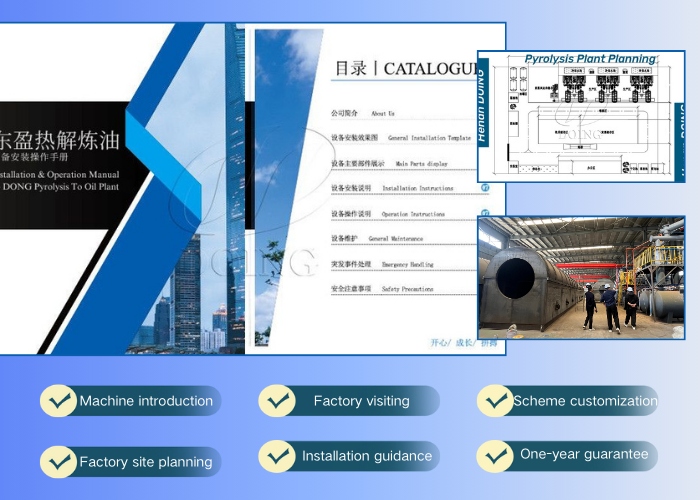

Professional pyrolysis distillation plant manufacturer services

Professional pyrolysis distillation plant manufacturer services

• Operation training: Provide on-site operation training for the Mexican customer's operators, covering equipment operating procedures, maintenance knowledge, and common troubleshooting techniques.

• After-sales support: After the installation and commissioning is completed, provide free warranty service for a certain period of time, and establish a long-term after-sales service mechanism to ensure that customers can get technical support in time if they encounter any problems during use.

Henan Doing specializes in the production of pyrolysis plant and waste oil distillation plant, and has rich experience and comprehensive service system. If you have equipment needs, you can reach out to Henan Doing for professional consultation.

PREV:Nothing

PREV:Nothing

NEXT:Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

NEXT:Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?