Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

In the market, there are two types of waste oil-to-diesel distillation machines. One is equipped with a horizontal reactor, while the other features a vertical reactor. So, how should one make a choice? This article aims to introduce the disparities between horizontal and vertical distillation reactors for refining waste oil into diesel.

Horizontal V.S. Vertical reactors of waste oil distillation plant

Horizontal V.S. Vertical reactors of waste oil distillation plant

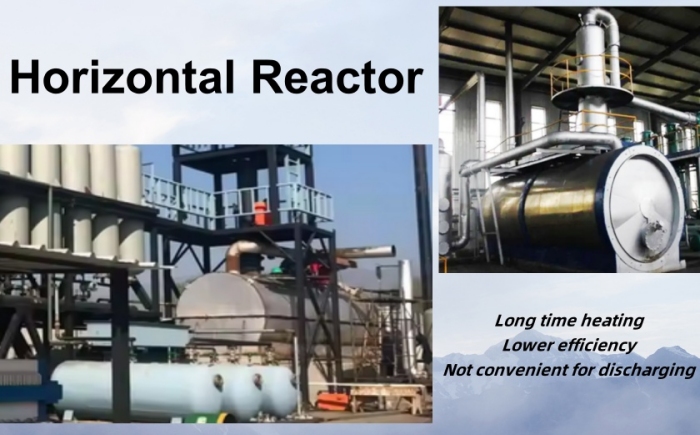

Traditional Horizontal Reactor for Waste Oil Distillation Plant:

①Efficiency: The horizontal reactor takes an extended period to heat up, typically ranging from two to three days, and continuous heating is required during this time.

Waste oil distillation plant with horizontal reactor

Waste oil distillation plant with horizontal reactor

②Safety: Due to the long heating duration, the reactor remains in a high-temperature state for an extended period, significantly reducing its service life. Additionally, prolonged heating also increases the likelihood of accidents. As the raw material is liquid heavy oil, during the rotation process, the reactor is affected by the inertia of the liquid, causing the support wheel to be prone to deformation and loosening.

③Slag Discharge: For the horizontal reactor, slag discharge can only be carried out after the asphalt has completely cooled. Manual entry into the reactor for excavation is necessary. This process is time-consuming and difficult.

2. Doing Group: Vertical Waste Oil Distillation Reactor with Thermal Oil Auxiliary Heating:

①Efficiency: DOING waste oil distillation plant utilizes a vertical reactor, which can ensure the efficiency of processing one batch of waste oil into diesel per day. With the assistance of the fast-heating thermal oil heating system, the efficient distillation time can be guaranteed.

Waste oil to diesel distillation reactor with fast heating system

Waste oil to diesel distillation reactor with fast heating system

②Safety: The ability to process one batch per day allows the reactor sufficient rest time, thereby increasing its service life.

③Slag Discharge: The slag discharge method of the vertical reactor significantly reduces the time and difficulty associated with slag removal. By opening the bottom slag discharge port before the asphalt condenses, the asphalt will be automatically discharged. Additionally, our equipment can also be equipped with an asphalt pump to further expedite the slag discharge process.

Waste oil distillation plant with horizontal reactor

Waste oil distillation plant with horizontal reactor

In conclusion, the vertical reactor for waste oil distillation plants is more widely favored and selected by customers. Henan Doing Company can customize the vertical waste oil distillation reactor to help you achieve efficient conversion of waste oil to diesel. Welcome to inquire about our waste oil distillation plant for detailed machine information, running videos, and price lists.

PREV:What is the Process of Waste Oil Distillation Plant and Its Advantages?

PREV:What is the Process of Waste Oil Distillation Plant and Its Advantages?

NEXT:How much waste oil can be processed by waste oil recycling distillation plant daily?

NEXT:How much waste oil can be processed by waste oil recycling distillation plant daily?

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated