How to make furnace oil from tyres? Guide to Tyre Oil Pyrolysis Process

Waste tyre pollution and treatment hazard

With the continuous improvement of living standards, the number of automobiles has surged globally. While cars bring unparalleled convenience to our daily lives, the ever-increasing volume of discarded tires(end of life tyres, called elts) presents a significant environmental challenge. These "black pollutants" can harm ecosystems and soil if not managed properly. The question then becomes: how to convert waste tyres into valuable resources efficiently and without causing secondary pollution?

Doing Group, a pioneer in industrial waste tyre recycling technology development, has been at the forefront of addressing this challenge. We have developed advanced waste tyre pyrolysis plants that provide a sustainable and profitable solution. Here we will guide you through the process of making furnace fuel oil from tyres using DOING tyre pyrolysis technology.

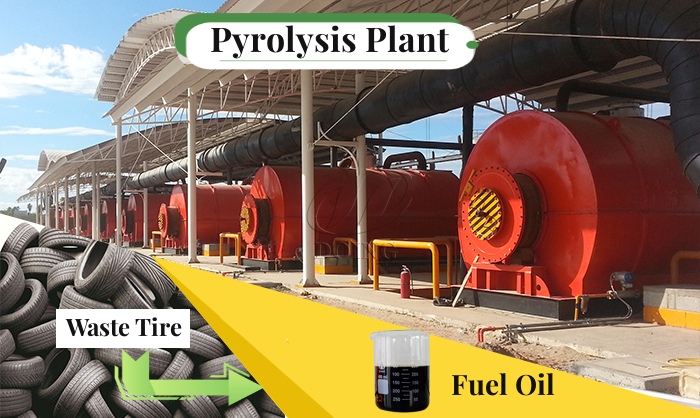

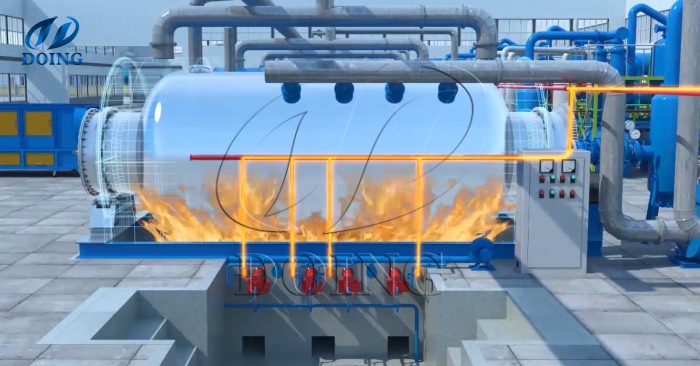

DOING Group's waste tyre pyrolysis plant

DOING Group's waste tyre pyrolysis plant

1. The Core Technology: Waste Tyre Pyrolysis Process

The fundamental principle behind making furnace oil from tyres lies in pyrolysis (thermal cracking). In a strictly controlled, oxygen-free environment within our tyre pyrolysis reactor, waste tires are subjected to high temperatures. This thermal decomposition process breaks down the complex hydrocarbon chains of the tire materials into valuable by-products: tyre furnace oil, carbon black, steel wire, and combustible gases.

DOING tyre furnace oil pyrolysis process is designed for optimal efficiency and environmental protection. Here's a detailed breakdown:

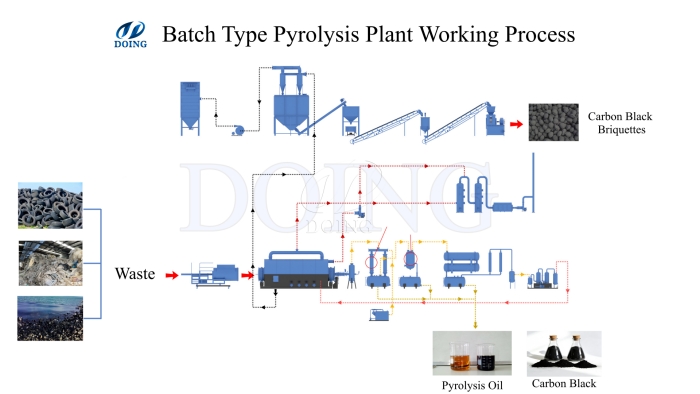

Waste tyre pyrolysis plant working process

Waste tyre pyrolysis plant working process

①Tire Feeding and Pre-treatment: Shredded or whole waste tires are fed into the sealed reaction vessel via an automatic feeding system. This ensures a consistent and controlled input for the pyrolysis process.

②High-Temperature Pyrolysis: The reactor is heated using external energy sources such as coal, wood, fuel oil, or natural gas. As the temperature rises, typically reaching between 200°C and 300°C, the tire materials begin to decompose, releasing heavy oil vapor and combustible gases. Precise temperature control is crucial to maximize oil yield and product quality.

③Crude Oil Vapor Condensation: The generated oil vapor first passes through a buffer chamber and then undergoes a process of cooling and deceleration within the dedicated condensation system. This system efficiently condenses the oil vapor into liquid heavy fuel oil, which is then collected in an oil storage tank. That’s the furnace oil extracted from waste tyres, also called tire pyrolysis oil TPO or tire derived fuel TDF.

④Carbon Black Discharge: The carbon black, a solid residue from the pyrolysis, is automatically discharged through a sealed underground channel. This sealed system prevents any release of dust or fumes, ensuring zero environmental pollution during discharge.

⑤Combustible Gas Recycling: The combustible gases produced are largely recycled back to the furnace to provide heat for the tyre pyrolysis reactor. This creates a self-sustaining heating loop, significantly reducing external fuel consumption and lowering operational costs. Any surplus gas can be stored for other heating applications.

Note: The exact oil yield and product composition can vary depending on the type of waste materials processed and the specific operating parameters of the tyre recycling pyrolysis plant.

Waste tyre pyrolysis materials and furnace oil yeild

Waste tyre pyrolysis materials and furnace oil yeild

| Waste Rubber Tyres Pyrolysis Oil Yield | |

| Big tires/Rubber tyre powder | 45-52% |

| Small tires | 35-40% |

| Rubber cable | 35% |

| Rubber Sole | 30% |

| Submarine cable | 75% |

| Other waste plastic pyrolysis feedstocks and oil yeilds | |

| PE | 95% |

| PP | 90% |

| PS | 90% |

| ABS | 40% |

| House garbage | 35-50% |

| Leftovers of paper/Paper mill waste | Wet 15-20%,dry 60% |

| Plastic cable | 80% |

| Plastic bag | 50% |

| PVC | Not suitable |

| PET | Not suitable |

2. The Valuable By-products and Their Applications

The tyre pyrolysis process transforms problematic rubber tyre waste into valuable commodities with diverse industrial applications:

a) Tyre Fuel Oil (Furnace Oil):

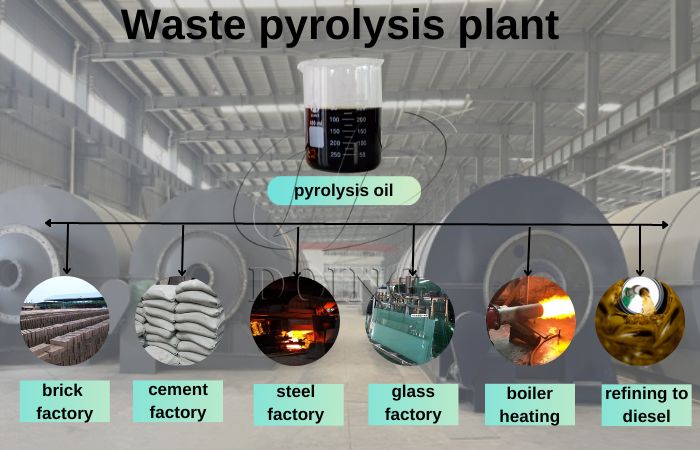

Waste tyre pyrolysis furnace oil usages

Waste tyre pyrolysis furnace oil usages

Produced tyre furnace oil is a high-quality heavy fuel oil with significant market demand.

Industrial Fuel: It serves as an excellent energy source for various industries, including cement plants, glass factories, brick factories, ceramic factories, galvanizing plants, steel mills, and industrial boilers.

Power Generation: It can be used in heavy oil generators for electricity production.

Further Refining: With DOING Group specialized waste oil distillation equipment with decolorization&deodorization refining units, this tyre furnace fuel oil can be further processed into tyre diesel. This high-grade diesel is suitable for use in trucks, tractors, and other heavy machinery, opening up even higher profit margins.

b) Carbon Black:

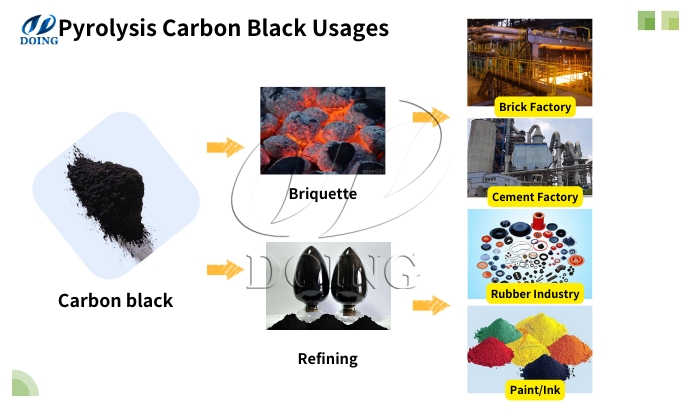

Tyre recovered carbon black applications

Tyre recovered carbon black applications

The carbon black recovered from tire pyrolysis is a valuable industrial material.

Heating and Burning: It can be processed into spherical carbon black or briquettes for use as a solid fuel source.

Rubber Industry: Ground to specific grades like N220, N330, N550, or N660, it is a crucial raw material for tire manufacturing, enhancing rubber properties.

Plastics Industry: It can be processed into masterbatch and sold to the plastics industry for coloring and enhancing polymer performance.

c) Steel Wire:

The steel wire recovered from tires is a significant source of revenue.

Direct Sale: It can be sold directly to steel plants for recycling.

Enhanced Value: Through our wire treatment programs, the steel wire can be further processed to achieve higher purity and tensile strength, fetching significantly higher prices, potentially up to $460 USD per ton.

d) Combustible Gas:

Tyre oil gas recovery for heating pyrolysis reactor

Tyre oil gas recovery for heating pyrolysis reactor

As mentioned, the combustible gases are primarily utilized for energy self-sufficiency.

Reactor Heating: Recycled to heat the pyrolysis reactor, drastically reducing reliance on external fuels and cutting operational costs.

Supplementary Heating: Surplus gas can be stored and used for heating other furnaces or processes within a facility.

3. Why Choose Manufacturer Doing Group for Your Tyre Pyrolysis Investment?

The technology for making furnace oil from tyres is mature, and with increasing government support for waste tyre recycling, this is a highly lucrative investment opportunity. Doing Group offers:

Advanced and Reliable Pyrolysis Equipment: Our waste tyre pyrolysis plants are engineered for high efficiency, durability, and safety. There are skid-mounted design, batch/semi-continuous/fully continuous working mode tyre pyrolysis plant to choose from, with daily processing capacity of 100kg to 50Ton/Set.

Environmental Compliance: We prioritize emission control and pollution prevention, ensuring our equipment meets stringent environmental standards.

Cost-Effective Solutions: Our technology maximizes resource recovery and energy efficiency, leading to significant operational cost savings and higher profits.

Comprehensive Support: From initial consultation and equipment customization to installation, training, and after-sales service, we provide end-to-end support.

Reliable tyre pyrolysis plant manufacturer DOING Company

Reliable tyre pyrolysis plant manufacturer DOING Company

Investing in waste tyre pyrolysis business is a wise decision for both profitability and environmental sustainability. It offers a pathway to transform a global waste problem into valuable resources. No matter you are looking for waste tyre recycling treatment solution or tyre furnace oil making solution, just please feel free to contact Doing Group today for a detailed consultation and to receive a customized tyre recycling pyrolysis plant proposal. Let us help you build a profitable and eco-friendly business.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated