How to deal with waste lubricating oil?

Waste lubricating oil

When the lubricating oil is used for a long time, its processing performance is degraded and wear is increased, so it is necessary to replace the new oil after a certain period of use. Since the amount of waste lubricating oil that is replaced every year in the world is quite large, the disposal of waste lubricating oil is also worthy of our attention. The following is a collection of common lubricant waste oil treatment methods:

Waste lubricating oil treatment 1. Discard

Discared waste lubricating oil

More serious is that the lubricating oil contains 3,4-benzo-flower (PAH) and other polycyclic aromatic hydrocarbons (mainly found in mineral base oils), which have been confirmed to have strong carcinogenic effects; chlorine-containing polycyclic aromatic hydrocarbons compounds such as polychlorinated biphenyls (PCBs) are also substances that have a strong toxic effect on humans; heavy metal salt additives contained in lubricating oils, and organic substances such as chlorine, sulfur, and phosphorus-containing extreme pressure antiwear agents are all human and biologically harmful substances, which are mixed into water and may eventually harm humans through various channels. Therefore, although the use of microorganisms in water and soil can slowly biodegrade waste oil, it takes a long time to use this natural purification effect, so the method of disposal is not preferable.

Waste lubricating oil treatment 2. Sprayed on the dust road

Sprayed on the road

Waste lubricating oil treatment 3. Flame

Waste lubricating oil flame

The use of waste lubricating oil as a fuel is a cost-effective treatment, but lubricating oil is a valuable natural resource. Since not all crude oil is suitable for the production of lubricating oil, almost all crude oil components can produce fuel oil. Moreover, the process of preparing lubricating oil from crude oil is much more complicated and costly than producing fuel oil. The use of lubricating oil as a fuel oil is a waste, so from the perspective of making full use of natural resources, it is not advisable to use simple incineration.

Moreover, the heavy metal oxides contained in the flue gas generated by combustion and the polycyclic aromatic hydrocarbon oxides produced by incomplete combustion may cause pollution and serious harm to human health in the air of the mud. The heavy metal oxides contained in the flue gas may come from leaded gasoline engine oils and lubricating oil additives containing barium, calcium, zinc, and the like. Among them, the most harmful to human health is lead oxide. A study by the US Environmental Protection Agency showed that exposure to air with an average lead concentration of 2 μg/m' for 3 months would have a significant adverse physiological impact on human health. If the US internal combustion engine oil is treated by direct incineration, it is necessary to dilute lead oxide with 1.87 × 10 'm' air to achieve an acceptable concentration of lead in the air. Moreover, the lead oxide formed after combustion exists in the state of ultrafine particles. If it is dispersed in the atmosphere, it is difficult to settle from the air, and it will float in the air for a long time. People breathe this heavy metal oxide or polycyclic aromatic hydrocarbon oxide. Contaminated air can seriously damage health.

Therefore, the waste oil used as fuel must be treated by various measures, such as chemical treatment to remove heavy metal impurities in the waste oil; a dust removal device is established in the flue of the oil burning furnace to prevent the smoke particles from entering the atmosphere; Light fuel oil reduces the amount of waste oil in the fuel and tries to make the fuel burn more fully, preventing harmful substances from being generated due to insufficient combustion.

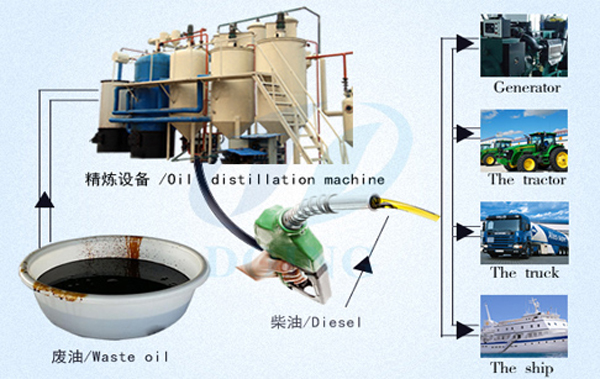

Waste lubricating oil treatment 4. Regeneration of non-standard diesel

Waste lubricating oil refining to diesel

What is the specific process for treating waste lubricating oil into recycled diesel?

Waste lubricating oil working process

2. The waste lubricating oil in the reaction kettle is subjected to high-temperature distillation treatment, and the impurities in the waste lubricating oil are distilled off at a high temperature and dropped into the reaction kettle, and the light oil and oil gas will enter the condensation system.

3. Light oil oil and gas will be liquefied into liquid in the condensing system and flow into the oil tank.

4. Finally, the light oil in the oil tank is degreased and desulfurized, and finally the clean and transparent non-standard diesel oil is obtained.

5. The asphalt analog produced during the combustion process will eventually be discharged outside the furnace.

In order to reduce the substances that may cause environmental pollution such as acid slag and waste water generated during chemical treatment, pollution-free processes that are conducive to environmental protection are being gradually adopted. In order to reduce the cost of lubricating oil regeneration, reclaimed oil is encouraged. Many countries also The corresponding measures and regulations have been formulated. DOING's waste lubricating oil refining equipment not only does not cause any pollution to the environment, but through this process we can get 85% non-standard diesel and 15% asphalt analog. Environmentally friendly and energy-saving, it is the general trend of waste bricating oil processing in the future.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

contact us

Product

project case

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated