How to make plastic to diesel ?

In order to reduce the adverse impact of waste plastics on the environment and maximize resource recovery, the circular economy strategy of recycling waste plastics into fuel has emerged. This article will delve into the specific process of converting waste plastic into diesel fuel.

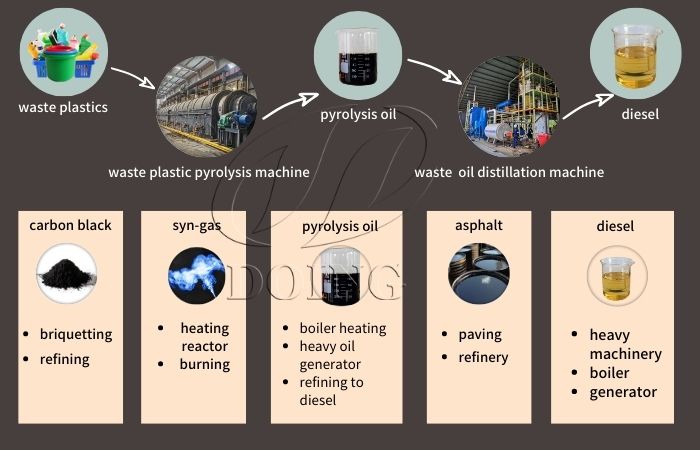

The waste plastic pyrolysis method and the pyrolysis oil refining method are two key processes for converting waste plastic into high quality non-standard diesel fuel. And this kind of diesel can be widely used in low speed engines, diesel generators and other heavy machinery like trucks, tractors, ships, boats, etc.

Plastic to diesel making process and final product applications

Plastic to diesel making process and final product applications

Most plastics are petroleum products, so we shouldn’t be surprised that they can be converted back to fuels that we can reuse. Basically, the principle of making plastic into diesel is that plastic is a polymer material. By heating the plastic in an oxygen-free state, the molecular bonds of the polymer are broken into small molecules, and the plastic is transformed from a solid state into a liquid state and a small amount of gas.

By heating the waste plastic, the molecular bonds of the polymer break and become small molecules. The plastic changes from solid to liquid and a small amount of gas. Through pyrolysis plant, waste plastic can be converted into fuel oil and flammable gases. And in order to improve the quality, smell and color of obtained fuel oil, plastic pyrolysis oil needs to be further refined by waste oil distillation plant.

Waste plastic to diesel pyrolysis distillation plant

Waste plastic to diesel pyrolysis distillation plant

Waste plastic to diesel machine working process

1. Feed the waste plastic into pyrolysis reactor manually or by auto-feeder.

2. Use coal/wood/natural gas/fuel oil/syn-gas/pyrolysis oil to heat the pyrolysis reactor of waste plastic pyrolysis plant.

3. After heating some time, the waste plastic will become oil gas, oil gas will be liquefied by the cooling pipe and condensers then will go into the oil tank. Here we get plastic pyrolysis oil, or you can also call it fuel oil. If you wanna get a different high quality diesel separately, through distillation technology, temperature control and catalyst process, we could get high quality non-standard diesel fuel.

Waste plastic oil to diesel distillation process

Waste plastic oil to diesel distillation process

4. Some gases (syngas) like Methane, Ethane, Propane, Butane, and Hydrogen cannot be liquefied under normal pressure and normal temperature will be recycled to fire furnace heating the reactor.

5. When using burning material heating the reactor, it will produce some smoke. These smokes will go into our de-dusting system, including the exhaust gas cleaning system and waste gas emission control system.

6. The purified exhaust gas will go into the chimney sucked by draft fan, and be discharged in line with environmental protection standards.

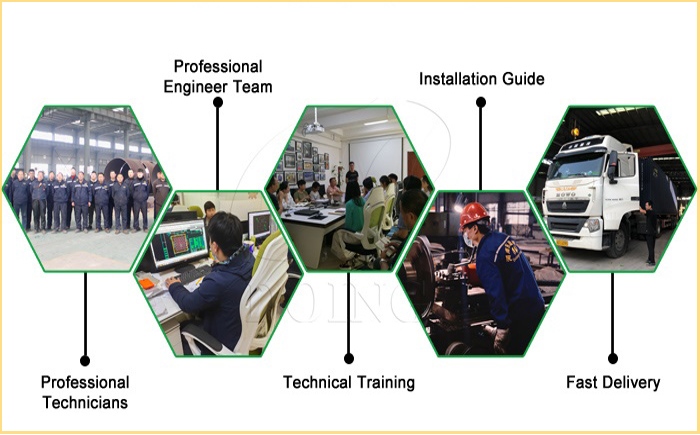

Technicial services of plastic to diesel plant manufacturer DOING Company

Technicial services of plastic to diesel plant manufacturer DOING Company

Overall, the conversion of waste plastics into diesel fuel is an important environmentally friendly and economically beneficial initiative that helps reduce the negative impact of plastic waste on the environment and provides a sustainable method of resource recycling. However, these plastic to diesel making processes require comprehensive consideration of environmental, economic, and technical factors to ensure their feasibility and sustainability in practical applications. Henan Doing Company has many years of waste plastic pyrolysis distillation technology and project installation experience. Welcome to consult!

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated