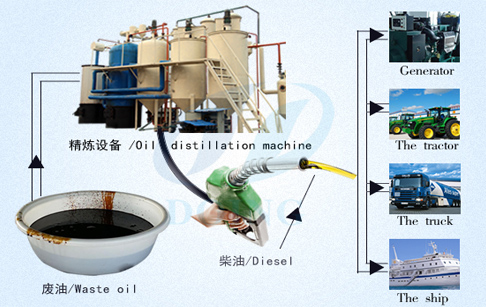

How to turn used oil into diesel?

Used oil

These include:

Industrial burner oil, where the used oil is dewatered, filtered and demineralised for use in industrial burners;

Mould oil to help release products from their moulds (e.g. pressed metal products, concrete);

Hydraulic oil;

Bitumen based products;

An additive in manufactured products; or

Re-refined base oil for use as a lubricant, hydraulic or transformer oil.

Used oil into diesel fuel plant

Used oil into diesel fuel plant adopt advance distillation technology that can turn used oil to diesel .

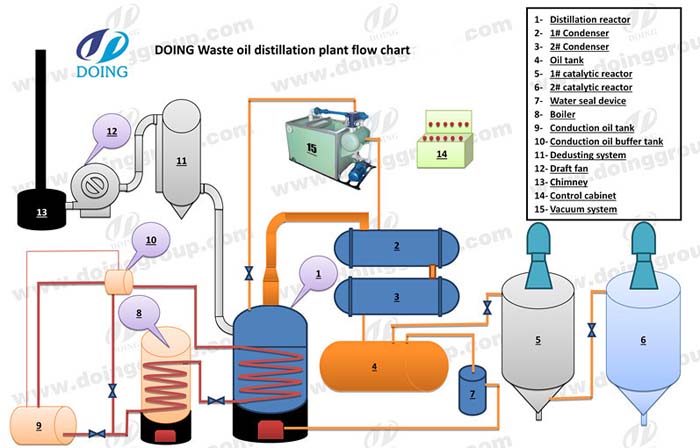

Used oil to diesel fuel plant working process

1. Pump waste oil into distillation reactor by oil pump.

2. Heat the reactor, and the liquid oil will slowly become oil gas, oil gas will go through catalytic chamber and condenser, then diesel will be cooled out first by controlling the temperature over 150 Celsius degrees.

3.The gasoline will be cooled out when the temperature is below 150 Celsius degrees, the rest of the system is same as pyrolysis system.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

contact us

Product

project case

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated