What is difference of batch waste tire pyrolysis plant and continuous waste tire pyrolysis plant

Batch pyrolysis plant and continuous pyrolysis plant

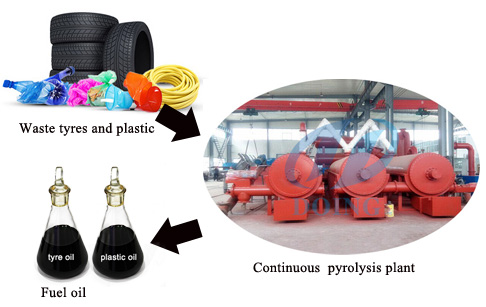

Both machine have the same working theory but different working process.

Batch waste tire pyrolysis plant:

Batch waste tire pyrolysis plant

People need to put raw material into reactor, then close feeding door.

After Burning the fuel material (coal, wood, natural gas or oil) in the furnace. Reactor will be slowly heated.the reactor need to heat 2 hours, then the raw material start to pyrolysis.

After finishing one turn pyrolysis process, the carbon blank start to discharge.

After cooling the reactor, then people can start the next batch.

Continuous waste tire pyrolysis plant

Continuous waste tire pyrolysis plant

Only need two person operate

Can keep feeding at least 20t waste tire in one time pyrolysis process

Waste tire Pyrolysis and carbon black discharge occur at the same time

Multiple reactors design for fully pyrolysis to get high oil rate

PLC computer control system ensure the safty

Indirect heating to prolong the usage life of the reactor

PREV:How is the continuous process for waste plasitc recycling to oil ?

PREV:How is the continuous process for waste plasitc recycling to oil ?

NEXT:What is the advantage of continuous waste tyre pyrolysis plant?

NEXT:What is the advantage of continuous waste tyre pyrolysis plant?

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

contact us

Product

project case

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated