What are the working steps of tyre pyrolysis oil color and smell removing system?

Our tyre pyrolysis oil color and smell removing system can further refine tyre pyrolysis oil into diesel like fuel. Many customers send inquires about what are the working steps of tyre pyrolysis oil color and smell removing system? So here we would like to briefly introduce the main working steps of tyre pyrolysis oil color and smell removing system in the following article.

DOING tyre pyrolysis oil color and smell removing system

DOING tyre pyrolysis oil color and smell removing system

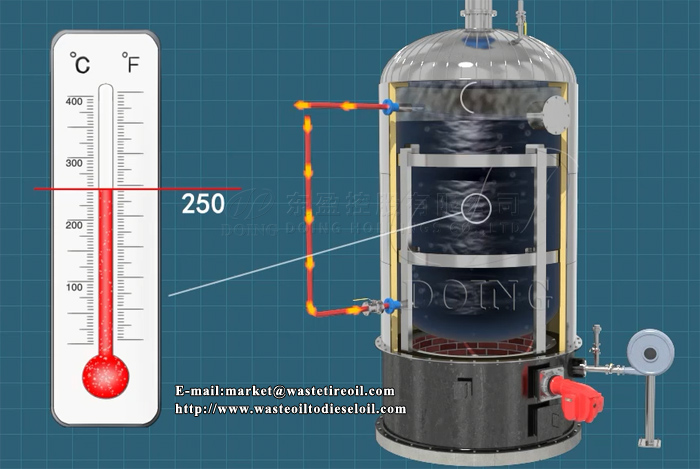

De-watering --The first step of waste tyre pyrolysis oil color and smell removing system

Normally waste tyre pyrolysis oil contains about 3% -5% water. When gas temperature reach 100 degrees, keep this temperature for a while to allow all the water removed from tyre pyrolysis oil in the form of vapor, to ensure the final diesel extracted from tyre pyrolysis oil has 0 water content.

De-watering

De-watering

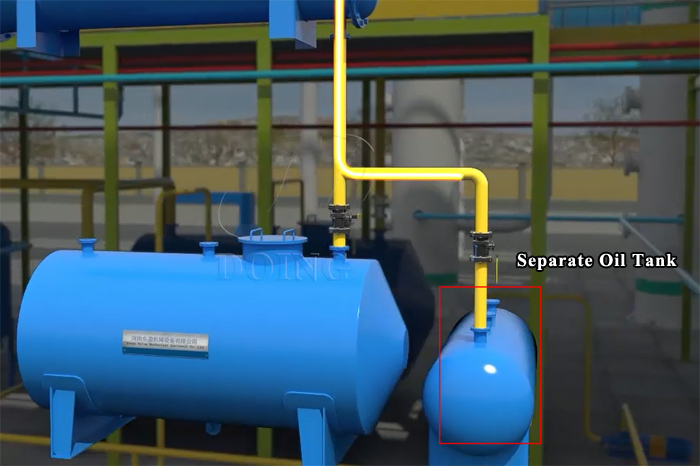

De-odoring--The second step of waste tyre pyrolysis oil color and smell removing system

During the early stage of oil distillation, the oil produced from tyre pyrolysis oil has bad odor, we also call it smelly fraction. Our tyre pyrolysis oil color and smell removing system can separate this small quantity of smelly oil from the final diesel and collect it into a separate oil tank.

Separate oil tank

Separate oil tank

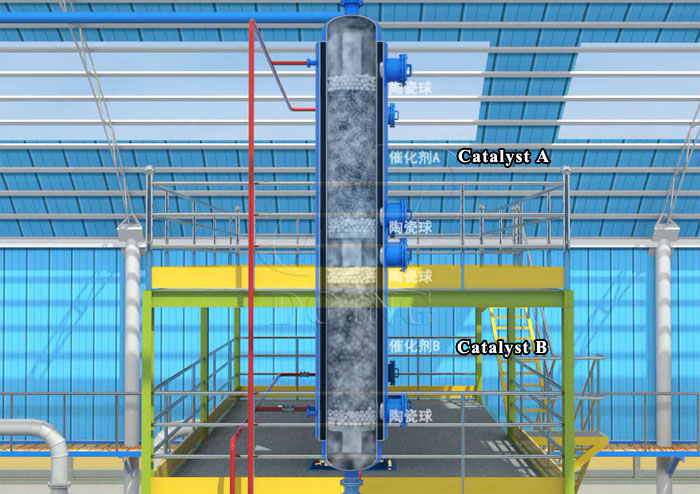

Purification and de-coloring---The 3rd step of waste tyre pyrolysis oil color and smell removing system

In the middle and final stage of oil distillation, the oil gas is treated by two kinds of catalyst, catalyst A and catalyst B. Function of catalyst B is to absorb impurities inside the oil gas and meanwhile remove the dark color to some extent. After processing by catalyst B, the pure oil gas will be processed by catalyst A, and function of catalyst A is to make heavy oil gas thoroughly break down. Then oil gas will flow into cooling system and condensed into diesel to be collected in the oil tank.

Purification and de-coloring

Purification and de-coloring

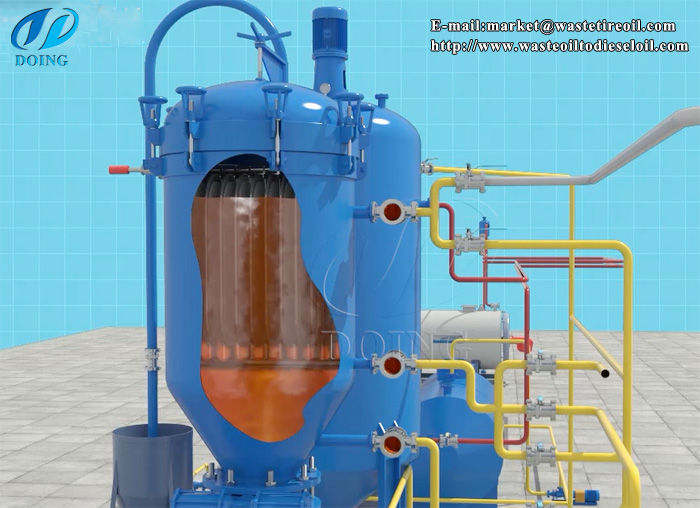

Further decoloring---The last step of waste tyre pyrolysis oil color and smell removing system

In order to keep a good oil color, decoloring agent is used into our waste tyre pyrolysis oil color and smell removing system to further remove the oil color, after that we will get final diesel.

Further decoloring

Further decoloring

The above is the main working step of our waste tyre pyrolysis oil color and smell removing system. If you wanna discuss with us more in details about this system, please feel free to contact with us.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia

-

15 TPD used tyre pyrolysis machine produced fuel oil in Brazil

-

Waste tire to diesel plant project installed in South Africa