How much plastic does it take to make a gallon of diesel?

Generally speaking, about 5.7kg to 13kg of waste plastic is needed in order to make a gallon of diesel. Here let us analyze how we get the detailed data related to making diesel from plastic.

To obtain diesel from waste plastic will need waste pyrolysis plant and waste oil refinery plant working together, getting pyrolysis fuel from waste pyrolysis plant firstly and then obtaining diesel through the further refinery of our waste oil refinery plant.

Waste plastic to diesel solutions

Waste plastic to diesel solutions

The oil output of waste plastic pyrolysis plant is not a fixed number and it varies from about 30% to 70% depending on the type and quality of plastics. For example, the oil yield of plastics from paper mill is just like 30%, but for PE and PP plastics, the oil yield can be as high as 70% or more, which can be also understood that our 10ton capacity waste pyrolysis plant can produce 3ton -7ton pyrolysis fuel oil in a day.

The diesel output of our waste oil refinery plant is as high as 80%, so from 3ton-7ton pyrolysis fuel, we can collect 2.4ton-5.6ton diesel fuel.

Therefore, from the above oil output of our waste pyrolysis plant and waste oil refinery plant, we can calculate how much plastic is needed to make a gallon of diesel.

However, there are many factors that can influence how much oil a pyrolysis plant produces from plastics. Waste pyrolysis plants and waste oil refinery plants with different technical processes and capacities will produce different amounts of fuel oil, even the season and machine operators sometimes also have an impact on how much oil the pyrolysis plant can produce from plastics.

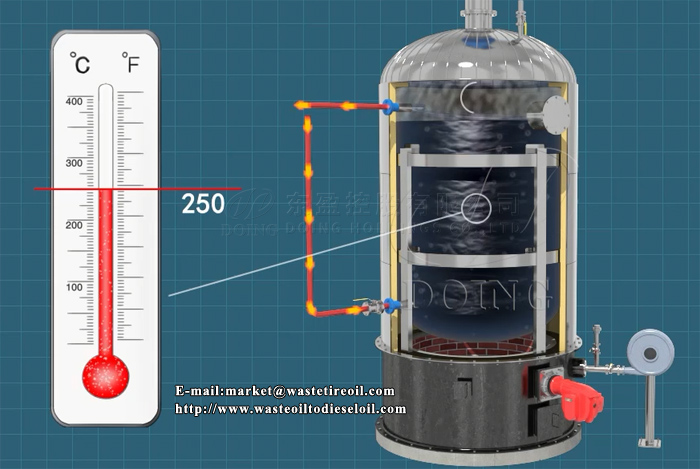

Temperature contral system

Temperature contral system

The cooling effect of waste plastic to diesel plants can also make great significance. Waste plastic to diesel plants with good technical process is sure to have a strong gas cooling system, which means higher oil yield.

Besides, the operation is also very important to decide the diesel output made from plastics. For example, correct operation always means a well-control of pyrolysis temperature, which will ensure all of the oil gas can be condensed and no wasting. So a skilled pyrolysis plant operator is indispensable for you to get more oil from plastics.

For more details and free quotations of waste plastic to diesel pyrolysis distillation plant, please inquiry Henan Doing Company. Our professional engineer team and sales manager will customize suitable solutions for making diesel from plastic and offer you all around technical support.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia