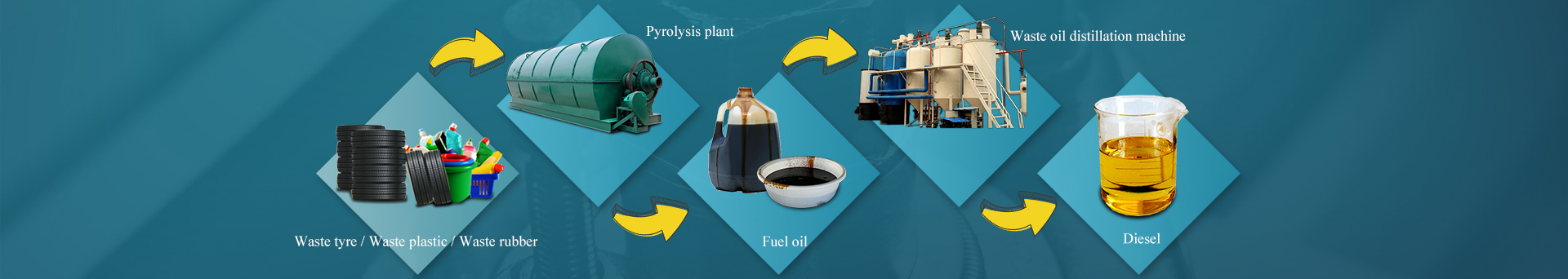

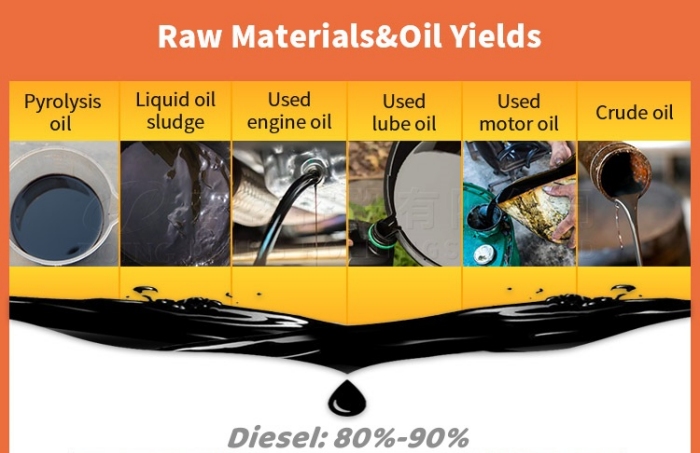

The Waste oil to diesel plants for sale from Henan Doing Company is designed and manufactured according to the principle of distillation and refinery. Waste oil to diesel plants can extract diesel from waste oil efficiently and environmentally under normal pressure and vacuum pressure. The waste oil to diesel conversation and recovery rate can reach as high as 80% -90%.

Waste oil to diesel plant can extract diesel from waste oil

Waste oil to diesel plant can extract diesel from waste oil

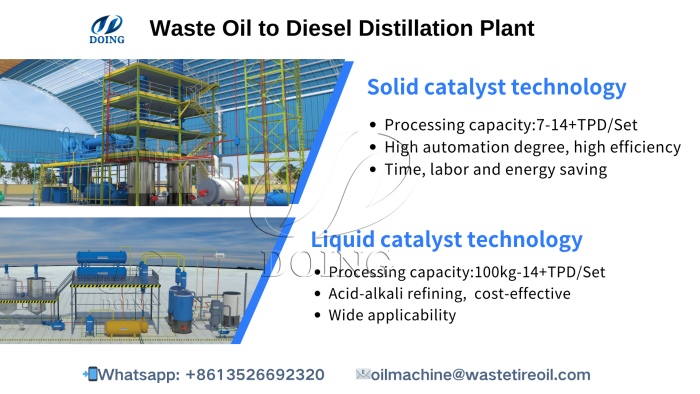

The main configurations of the waste oil to diesel plant are: rapid heating system, distillation reactor, catalytic tank, condenser, oil tank, oil pump, deep purification system, exhaust gas treatment system, etc. Doing's waste oil to diesel plant has different models, and there are solid and liquid waste oil catalytic recovery technologies to choose from, and the corresponding configurations will also be slightly changed. Welcome to send us your detailed requirements, and our engineer and sales team will customize you suitable machine solution.

Liquid and catalyst technologies of waste oil to diesel plant

Liquid and catalyst technologies of waste oil to diesel plant

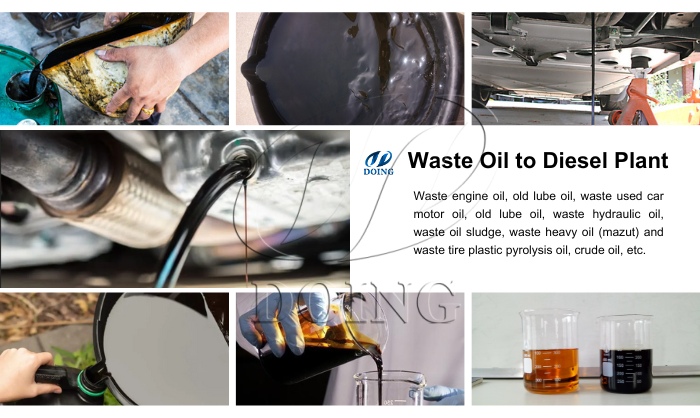

Waste oil mainly means the waste lube oil generated from all kinds of machinery, vehicles and ships. We also call it waste engine oil, used motor oil, old lubricant oil, black heavy oil(mazut), waste oil sludge, etc. It's caused by the lube oil used in all kinds of engines after a long time of use. Due to the outside pollution, the lube oil will generate a large quantity of gum and oxide, which will reduce the friction control, wear resistance, cooling, sealing and vibration attenuation of the lube oil, which have to be changed by new lube oil.

The extensive use of lube oil, especially in countries like China where over 4 million tons of waste engine oil are generated monthly from vehicles and ships, drove the development of this waste oil to diesel distillation plants. In the past, much of this waste oil was either disposed of improperly or burned directly, leading to severe environmental pollution and wastage of resources. This not only affects oil prices and resource availability but also imposes environmental and economic burdens. Proper management of waste engine oil through recycling is crucial for ensuring sustainable transportation and a clean environment for current and future generations.

Waste oils we got for collection and recycling into diesel

Waste oils we got for collection and recycling into diesel

While we often recycle materials like newspapers, aluminum cans, glass, and plastic bottles, waste engine oil recycling is equally important. Efforts by the petroleum industry and other groups aim to collect waste engine oil efficiently, preventing its contamination of waterways and groundwater while integrating it back into the recycling system.

Recycling just two gallons of waste oil can generate enough electricity to power an average household for nearly 24 hours. DOING Company specializes in waste recycling machinery, with the Waste Oil to Diesel Plant being a flagship product. Also known as an oil distillation machine, it refines waste or used oil through distillation and chemical catalyst processes, producing clean fuel for various applications.

The raw materials of waste oil to diesel plant can be waste engine oil, used car motor oil, old lube oil, waste hydraulic oil, waste oil sludge, waste heavy oil (mazut) and waste tire plastic pyrolysis oil, crude oil, etc.

Raw materials of waste oil to diesel plant

Raw materials of waste oil to diesel plant

1. Preparation of Waste Oil Raw Material: Gather waste oil raw material, such as used engine oil, and pump it into the distillation reactor. Simultaneously, activate the fast heating system to heat the conducting oil.

2. Heating for Distillation: Heat both the burner and the conducting oil simultaneously to rapidly increase the temperature, initiating high-temperature distillation. The heat transfer oil reaches temperatures of 250 to 380 degrees Celsius, causing continuous distillation of oil and gas. Note: When utilizing advanced solid catalyst technology in the waste oil to diesel plant, the oil gas undergoes purification in the catalyst tower before cooling.

3. Cooling: The distilled oil gas enters the multi-stage condenser, where it condenses into oil and is subsequently stored in an oil tank.

4. Chemical Process for Cleaning the Distillation Oil: If liquid catalyst technology is employed, further purification of the distillation oil is achieved through acid and alkali treatments to obtain high-quality diesel. Alternatively, the distillation oil can undergo fine filtration via decolorization tanks and blade filters to yield clean, brightly-colored non-standard diesel.

5. Collection of Final Diesel Products: Following the waste oil to diesel distillation process described above, the diesel can be collected, while the bitumen/asphalt residue can be either retained for self-use or sold.

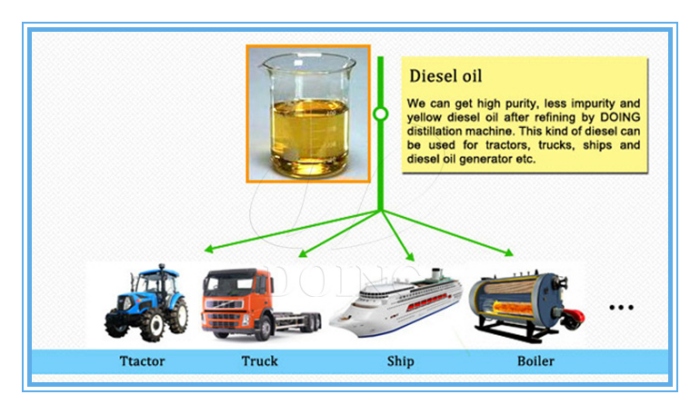

You can get about 80-85% diesel, 10% asphalt, 5% syn-gas from waste oil to diesel plant. The diesel obtained from waste oil to diesel plant can be used in tractors, trucks, diesel oil generators, ships, heavy machinery with low speed diesel engines, road paving roller, etc. As for the asphalt(bitumen), it can be used for paving roads or asphalt refinery plants for further refining.

Uses of diesel obtained from waste oil to diesel plant

Uses of diesel obtained from waste oil to diesel plant

1. Coil heater with conduction oil heating method

Coil heater can make heating evenly and fast, it can keep processing 3 batches of waste oil in 2 days without stopping; Conduction oil is recycling use, which can save a lot of heating fuel for you.

2. Environmental protection

All the systems of waste oil to diesel plant are sealed and we have specially designed environmental control devices for smoke and odor. Ensure that waste oil to diesel plant is pollution-free to the environment.

3. Vertical reactor

Waste oil to diesel plant uses a vertically designed reactor, which is very easy to discharge asphalt and do cleaning, making operation easier and increasing oil conversion.

4. High efficiency and energy saving

This equipment adopts a high-efficiency and energy-saving catalytic distillation process, which can fully convert waste oil, making the diesel yield reach more than 85%, greatly improving energy utilization and reducing energy consumption.

| NO. | Items | Contents |

| 1 | Capacity |

100/500kg, 1T/D, 5T/D, 7T/D, 10T/D, 14T/D, etc. |

| 2 | Raw material |

Tire/plastic pyrolysis oil, waste engine oil, old lube oil, watse motor oil, heavy oil, crude oil, etc. |

| 3 | Structural form | Vertical |

| 4 | Outputs | Diesel, asphalt(bitumen) |

| 5 | Diesel yield | 80-85% |

| 6 | Operating pressure | Normal |

| 7 | Material of Reactor |

Q345R/245R boiler plate/Stainless steel |

| 8 | Thickness of Reactor | 12/14/16mm |

| 9 | Safety standard | Pressure vessel standard |

| 10 | Total power | 24.5KW |

| 11 | Mode of cooling | Recycled water cooling |

| 12 | Required water | 40m³ for recycling use |

| 13 | Heating method | Recycled conduction oil heating with fuel heating |

| 14 | Discharge way | Automatically |

| 15 | Noise dB(A) | ≤85 |

| 16 | Running process | Semi-continuous |

| 17 | Delivery time | 20days |

| 18 | Weight | 20-50T (depends on the capacity) |

As a leader in China's machinery manufacturing industry, Henan DOING has been continuously reforming and innovating, and its waste oil to diesel plant has been sold to more than 40 countries and regions.

Waste oil to diesel plant installed in China and other countries

Waste oil to diesel plant installed in China and other countries

We have extensive experience in the construction of waste oil recycling projects and can provide customers with full-process integrated services. If you are interested in our waste oil to diesel plant or have any questions, please leave a message to us, and our professional engineer will give you a satisfactory reply.