How many ways are there to regenerate waste engine oil to diesel?

After 12 years of technological innovation and precipitation, Henan DOING Company currently provides two main methods for the regeneration of waste engine oil to diesel: one is the acid-base refining method, and the solid catalyst refining method.

1. Acid-base refining method

Pump the waste engine oil (waste lubricating oil) into the istillation reaction of the waste engine oil refining machine. After distillation and purification, the preliminary form of diesel oil will be extracted. Then the liquid preliminary form of diesel oil will be further refined into non-standard diesel oil through the processes of pickling, alkali cleaning and filtration.

The acid-base waste oil

The acid-base waste oil

2. Solid catalyst refining method

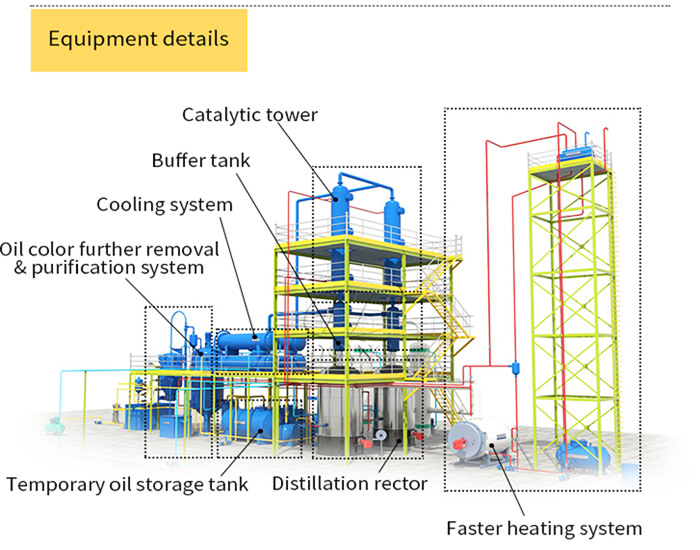

First, pump the waste engine oil into the reaction of the waste engine oil refining machine, and the waste engine oil will be cracked into oil gas by heating conduction oil at the bottom of the distillation reactor and the coil type in the reactor. Then the oil gas enters the multi-stage catalytic tower for refining and regeneration. There are multiple layers of packing in the catalytic tower, and catalysts with different functions are placed in it, such as degumming, dewaxing and decolorizing catalysts. The catalyzed oil gas enters the condensation system for cooling into diesel oil.

New design waste oil distillation plant 3D picture

New design waste oil distillation plant 3D picture

The difference between these two waste engine oil to diesel regeneration methods is: the former method is to crack waste engine oil into liquid fuel oil, then refine the liquid oil to obtain diesel oil; the other method is to crack waste engine oil into oil gas, then refining the oil gas with solid catalysts, then the oil gas will be condensed into diesel oil. In comparison, the first method is cost-effetive, but it takes a certain amount of time and manpower. And the second method is efficient, energy and labor saving, but its upfront costs higher than the first method.

No matter which method you choose to convert waste engine oil to diesel oil, we can customize different types of waste engine oil refining machine according to your needs. Welcome to contact us at any time, Henan Doing Company has professional sales managers and technicians to introduce the machine details, customize solutions and send quotations to you!

PREV:How much diesel can we extract from 10ton of pyrolysis oil?

PREV:How much diesel can we extract from 10ton of pyrolysis oil?

NEXT:Is it a profitable business to set up waste oil refinery plants?

NEXT:Is it a profitable business to set up waste oil refinery plants?

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated