How does the waste oil distillation machine work?

We all know that pyrolysis oil can be refined into diesel through waste oil distillation machine. Diesel is purer than pyrolysis oil and can be used in more places. However, do you know how the waste oil distillation machine works? Compared with the pyrolysis plant, its processing technology is more sophisticated and complicated. Let's take a look at it in detail below.

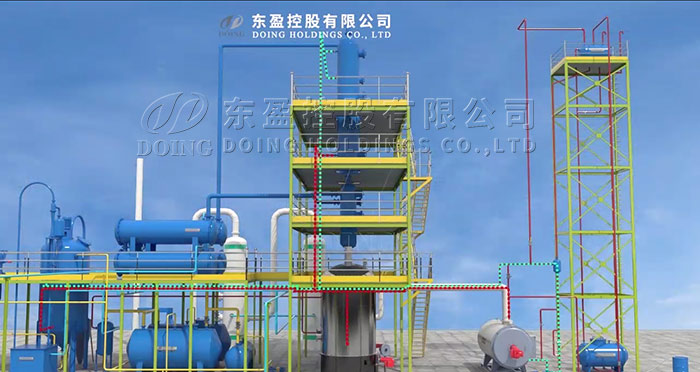

Waste oil distillation machine

Waste oil distillation machine

1. Pretreatment of heat transfer oil and condensed water

Heat-conducting oil circulation of waste oil diatillation machine

Heat-conducting oil circulation of waste oil diatillation machine

The waste oil distillation machine needs to be pre-prepared for heat-conducting oil circulation. Then start the oil injection pump, and send the oil to the expansion tank. The heat transfer oil gradually fills the entire system by its own weight through the expansion tube. Turn on the cooling circulating water pump to make the condensed water circulate normally in the horizontal condenser.

2. High temperature distillation

High temperature distillation

High temperature distillation

The oil pump is used to transport raw materials such as waste engine oil to the distillation reactor, and the heat transfer oil and the burner are used to heat the reactor at the same time. In a high temperature and oxygen-free environment, the distillation reactor will produce oil and gas after reaching a certain temperature.

3. Condensed into oil

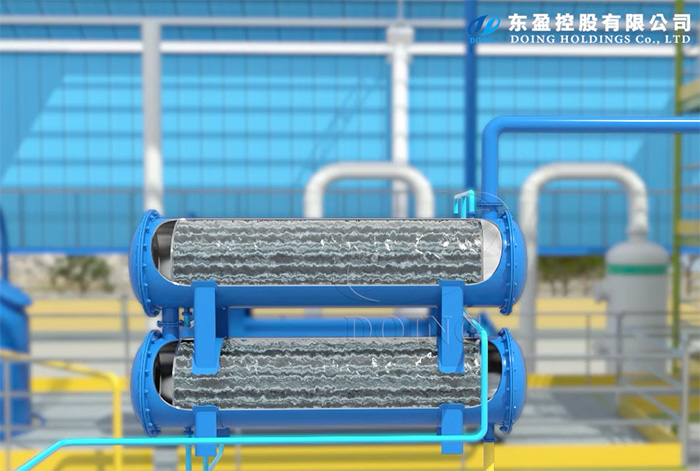

Condensed into oil

Condensed into oil

The heat-conducting oil heats the distillation reactor to 250 degrees Celsius, allowing the water and emulsified oil to fully evaporate. After buffering in the buffer tank, it enters the horizontal condenser, where it condenses into oil and is finally stored in the first fraction tank.

The heat-conducting oil and the burner are heated simultaneously to the distillation reactor to 380-400 degrees Celsius, there will be oil and gas volatilization, after buffering in the buffer tank, it enters the horizontal condenser and condenses into oil, which is stored in the second distillation tank.

The temperature of the reactor continues to be maintained at 380-400 degrees Celsius. The volatilized oil gas passes through the buffer tank and is catalyzed by the catalytic tower.Then it enters the horizontal condenser, and is condensed into oil to be stored in the third fraction tank.

4. Exhaust gas purification

The waste oil distillation machine is equipped with tail gas purification device, the non-condensable oil and gas in the condensing system is purified by a water seal and used as fuel to heat the distillation reactor.

5. Decolorization and deodorization

Feed the oil in the oil tank into the decolorizing pot, and the white clay is added to stir to decolorize. Then the oil fully mixed with the white clay is pumped into the leaf filter to obtain a clear color oil, which is followed by finely filtered to remove impurities. You can get clean, bright non-standard diesel. This is the fine point of waste oil distillation machine, which needs to go through multiple filtration.

6. Flue gas treatment

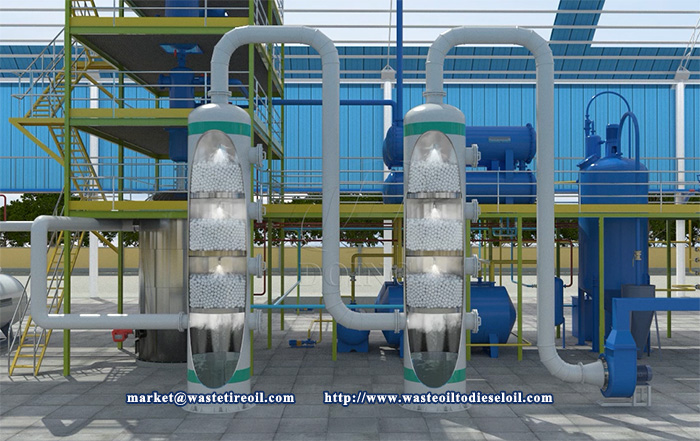

Desulfurization tower

Desulfurization tower

The flue gas generated by the heat-conducting oil furnace and the reactor is processed by the desulfurization tower and discharged into the atmosphere after reaching the national emission standard.

If you have waste tires or waste plastics on hand, you can also pyrolyze them into oil first, and then refine it into diesel through waste oil distillation machine. Doing has formed a mature operating mechanism on pyrolysis plant and distillation machine. Our salespersons will make the most suitable plan according to your needs. Welcome to contact us anytime.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated