What is crude oil distillation?

Crude oil distillation machine

The crude oil obtained by mining is a dark viscous liquid, which contains a large amount of impurities such as sand and salt water in addition to sulfides. Since crude oil is a hydrocarbon, it cannot be used directly as a fuel or as a base compound for the production of other useful substances. However, the crude oil can be distilled at high temperature to separate the impurities in the crude oil, thereby obtaining clean and transparent non-standard diesel oil.

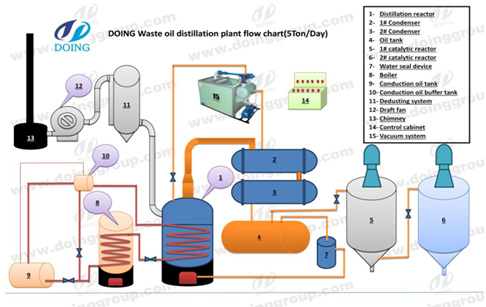

The specific process of crude oil distillation is as follows:

Crude oil distillation working process

1. Pour the crude oil into the reactor and heat it at high temperature to distill out the impurities in the crude oil and light oil and gas.

2. Light oil, oil and gas under the effect of high and low pressure, into the condensing system, liquefied into light oil falls into the tank.

3. The desulfurization of the light oil obtained is finally diesel oil.

4. Remove the asphalt separated by distillation.

Take 10T's equipment as an example,through this process, we can get 80-85% of diesel and 15-20% of bitumen. We will use the following input and output to conduct a profit analysis.

Operating costs.

DoingGroup's 10T distillation machine profits analysis

Waste oil: 10 tons X288 USD/ton = 2868USD

Heating the fuel can use any of the following:

1) Coal: 0.4 tons X 64 dollars/ton = 25 dollars

2) Fuel: 0.6 tons x 478 dollars/ton = 287 dollars

3) Diesel: 0.5 tons X 765USD/ton = 382 dollars

4) Natural gas: 200m23 X 0.36USD / m3 = 72USD

Power consumption: 25KW / h X O.16USD X 20h = 80h

Water consumption: water reuse, almost no consumption

Workers: 1-2 people X 16USD = 32 dollars

Earnings/day

Fuel: 8 tons X 765 dollars/ton = 6118 dollars

Asphalt: 1.5 tons X 175USD/ton = 263 dollars

Profit/day (calculated on fuel diesel) $3017.

Moreover, DoingGroup's crude oil distillation equipment has two alternative systems:

Rapid heating system:

The rapid heating system of the refining equipment uses a circulating heating medium, which on the one hand can save fuel and on the other hand it can speed up the distillation speed.

Diesel purification system:

The diesel oil refined by the standard refining system is brownish yellow. If you want to get better color diesel, we can also provide a deep purification system, and you can always get a pale yellow diesel product.

The main advantages of DoingGroup's crude oil distillation equipment:

DoungGroup's distillation machine

1. Double heating system, short heating time, rapid heating, improve equipment operation efficiency.

2. Vertical design, automatic slagging, saving manpower.

3. Semi-continuous equipment, moderate investment, and the operation is simple compared to intermittent equipment.

4. Cooling type is circulating water cooling, with almost no consumption.

5. Customers can customize small model trial production equipment according to their own needs and budget.

The principle of crude oil distillation is simple, but it is possible to use this principle to obtain the maximum oil yield, and there are not many technologies that will not cause environmental pollution. DoingGroup's crude oil distillation equipment has the above advantages. Any equipment problems, please feel free to contact us! !

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

contact us

Product

project case

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated