What is distillation ?

Distilaltion

Distillation is a widely used method for separating mixtures based on differences in the conditions required to change the phase of components of the mixture. To separate a mixture of liquids, the liquid can be heated to force components, which have different boiling points, into the gas phase. The gas is then condensed back into liquid form and collected.

Repeating the process on the collected liquid to improve the purity of the product is called double distillation. Although the term is most commonly applied to liquids, the reverse process can be used to separate gases by liquefying components using changes in temperature and/or pressure.

A waste oil distillation plant that performs distillation is called a distillery. The apparatus used to perform distillation is called a still.

Uses of Distillation

Distillation is used for many commercial processes, such as the production of gasoline, distilled water, xylene, alcohol, paraffin, kerosene, and many other liquids. Gas may be liquefied and separate. For example: nitrogen, oxygen, and argon are distilled from air.

Types of Distillation

Types of distillation include simple distillation, fractional distillation (different volatile 'fractions' are collected as they are produced), and destructive distillation (usually, a material is heated so that it decomposes into compounds for collection).

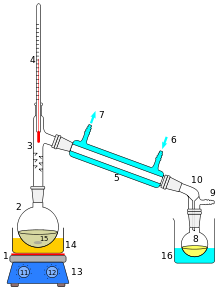

Simple Distillation

Simple distillation may be used when the boiling points of two liquids are significantly different from each other or to separate liquids from solids or nonvolatile components. In simple distillation, a mixture is heated to change the most volatile component from a liquid into vapor.

The vapor rises and passes into a condenser. Usually, the condenser is cooled (e.g., by running cold water around it) to promote condensation of the vapor, which is collected.

Steam Distillation

Steam distillation is used to separate heat-sensitive components. Steam is added to the mixture, causing some of it to vaporize. This vapor is cooled and condensed into two liquid fractions. Sometimes the fractions are collected separately, or they may have different density values, so they separate on their own. An example is steam distillation of flowers to yield essential oil and a water-based distillate.

Fractional Distillation

Fractional distillation is used when the boiling points of the components of a mixture are close to each other, as determined using Raoult's law. A fractionating column is used to separate the components used a series of distillations called rectification. In fractional distillation, a mixture is heated so vapor rises and enters the fractionating column. As the vapor cools, it condenses on the packing material of the column. The heat of rising vapor causes this liquid to vaporize again, moving it along the column and eventually yielding a higher purity sample of the more volatile component of the mixture.

Vacuum Distillation

Vacuum distillation is used to separate components that have high boiling points. Lowering the pressure of the apparatus also lowers boiling points. Otherwise, the process is similar to other forms of distillation. Vacuum distillation is particularly useful when the normal boiling point exceeds the decomposition temperature of a compound.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

contact us

Product

project case

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated