Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

In October 2025, DOING 30 tons of waste oil distillation machine project installed in Kazakhstan. Below is a photo from the project site:

Installation of DOING 30 tons of mazut oil distillation machine in Kazakhstan

Installation of DOING 30 tons of mazut oil distillation machine in Kazakhstan

Customer Background

Based in Kazakhstan, this customer was in search of high-quality equipment to convert waste oil into diesel. After conducting in-depth research and assessing multiple machinery manufacturers, they visited DOING factory to examine the design and quality of our distillation machines. The customer was impressed by our advanced technology and precision engineering, leading them to select DOING as their trusted supplier for this important project.

Project Details

In early May 2025, the customer confirmed an order for two 15-ton waste oil distillation units, along with supporting systems. The complete set of equipment includes:

Two 15-ton waste oil distillation machines

Two shared heat transfer oil furnaces

Two shared desulfurization towers

White clay decolorization systems

Burners

DOING patented catalysts

Easy-to-operate control panels

For detailed specifications and more information about the equipment, please refer to this article: Shipment of DOING 30 tons of waste oil recycling refinery machine to Kazakhstan.

Upon receiving the order, the DOING team worked diligently at the factory to complete the manufacturing process and prepare the equipment for shipment. By July 2025, all units and components were fully ready, ensuring the equipment was delivered to Kazakhstan on time and without disruptions.

Shipment of DOING mazut oil distillation equipment to Kazakhstan

Shipment of DOING mazut oil distillation equipment to Kazakhstan

Installation and Commissioning

In October 2025, DOING dispatched engineers to the project site in Kazakhstan to supervise the installation and commissioning of the equipment. The installation team carried out the setup of the distillation units with great care, making sure all systems were properly connected and fully functional.

To guarantee smooth long-term operation, DOING also provided comprehensive training for the customer’s staff. This training covered key areas such as the distillation machine’s operation, maintenance, and safety protocols. The training equipped the local team with the confidence to operate the equipment effectively, supporting sustained productivity and reducing potential downtime.

DOING perfect service

DOING perfect service

Project Outcome

By October 2025, the 30-ton waste oil distillation machine was fully installed and operating smoothly. The customer can now efficiently convert waste oil into high-quality diesel, which has significantly boosted their production capacity and strengthened their sustainability initiatives.

The successful installation of this 30-ton waste oil distillation machine in Kazakhstan showcases the efficiency and reliability of DOING’s products. From manufacturing and delivery to installation and staff training, we ensured every step of the process went seamlessly, allowing the customer to start using the equipment without any issues.

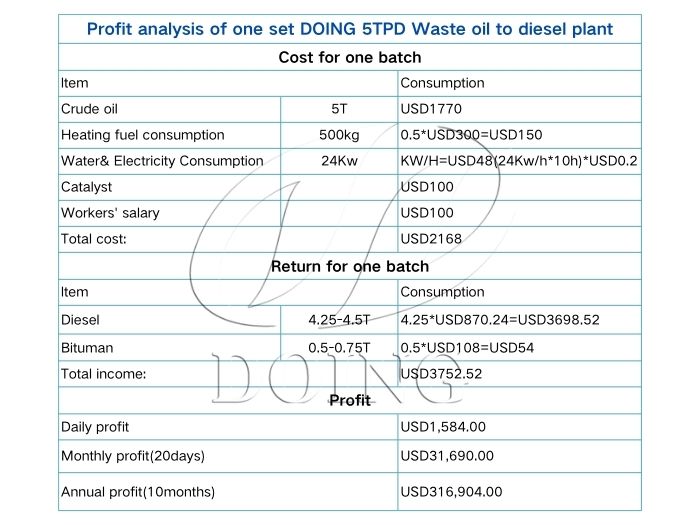

Profit analysis of waste oil distillation machine

Profit analysis of waste oil distillation machine

We are eager to partner with more businesses worldwide. If you need reliable waste recovery or waste oil distillation solutions to enhance production efficiency and increase profits, please get in touch with us.

PREV:Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

PREV:Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

NEXT:DOING 15TPD plastic pyrolysis machine installed in Jordan

NEXT:DOING 15TPD plastic pyrolysis machine installed in Jordan

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?