How does the continuous waste tire pyrolysis plant work?

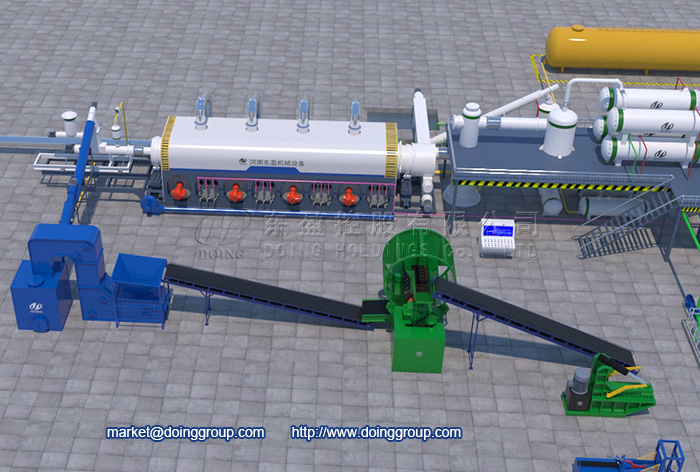

Continuous waste tire pyrolysis plant is based on batch pyrolysis plant, and the mainly process is consistent, but the operation is more intelligent and convenient, and saves a lot of manpower and material resources, and the output can reach 100 tons per day.

DOING continuous waste tire pyrolysis plant

DOING continuous waste tire pyrolysis plant

Then how does the continuous waste tire pyrolysis plant work?

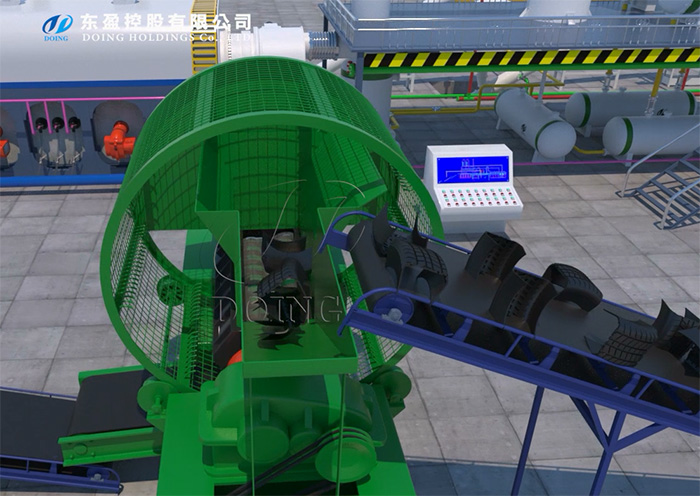

● Waste tire pretreatment

Different from the batch pyrolysis plant, before feeding, we need to draw out the steel wire in the tire to crush the tire into fine rubber powder. On the one hand, it can ensure the continuous feeding of raw materials in the sealed feeding system; another, we don't need to open the feeder door and pull out the wire, which can save a lot of time so that the continuous waste tire pyrolysis plant can run continuously.

Waste tire pretreatment

Waste tire pretreatment

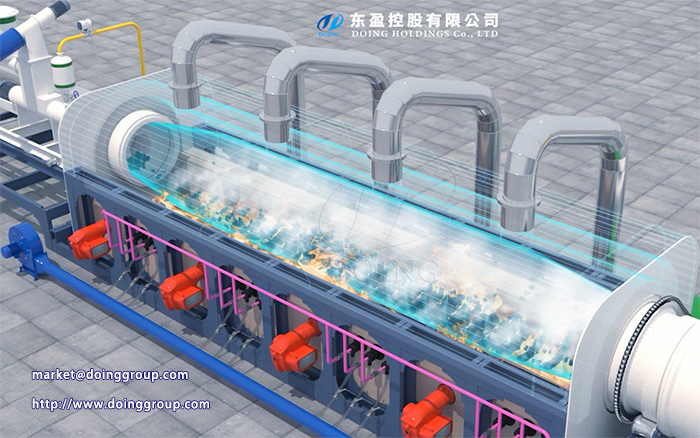

● Feeding and heating

The continuous waste tire pyrolysis plant adopts spiral sealed conveyor for feeding. The feeding speed of the feeder can be set to control the whole process in an orderly and we set the air shutoff device in the feeder, which can ensure no air enters into reactor and reasonably avoids the hidden danger of stability.

Another, continuous waste tire pyrolysis plant adopts indirect heating system. The heating flame does not directly contact the inner wall of reactor. The heating source is connected with the pyrolysis system through the combustion chamber and heated by hot air or hot gas conduction. In this way, the service life of the reactor can be prolonged and the heating is even.

Indirect heating system

Indirect heating system

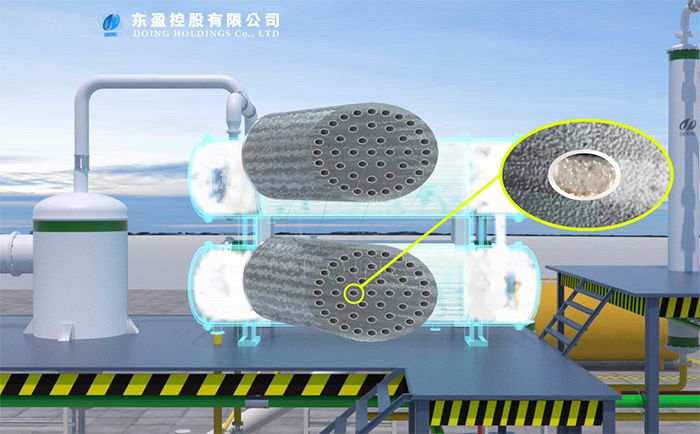

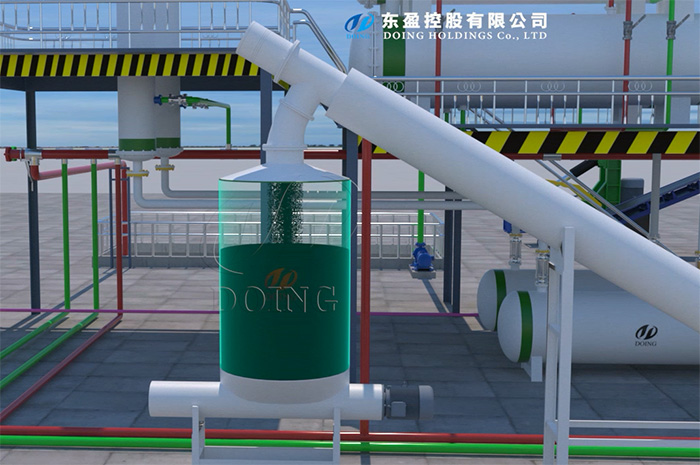

● Cooling system

We adopts the latest condensation technology. Before the oil gas enters the condenser, it will pass through two devices. The first one is catalytic chamber, which can discharge some carbon black from oil gas to play a cleaning. Another is the buffer condenser. This is our latest design. In order to prevent a large amount of oil gas directly entering the condenser and ensure the safety of the continuous waste tire pyrolysis plant, so we can cool a part of the oil gas in this two position. After that, we set four 800 * 2050 condensers, and the total cooling area is more than 60 square meters, which condensation effect is very good.

Tube condensers

Tube condensers

● Discharge

We design a screw conveyor used to connect the end of reactor for slag discharge, and there is circulating water cooling layer outside the screw conveyor, which can cool the discharged carbon black and avoid high temperature damage to the slag discharge device.

Slag discharge device

Slag discharge device

Above is the main working process of continuous waste tire pyrolysis plant. Henan DOING have mature technology and rich practical experience. If you are facing the problem of waste tires pollution or disposal and need such a system urgently, please contact us without hesitation, Doing Company will provide you with the best solution.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated