Continuous Process Rubber Tyre Recycling Plant

The continuous process rubber tyre recycling plant is relative to the bathch tire pyrolysis plant. Continuous process rubber tyre recycling plant can achieve continuous feed and continuous slag discharge, and achieve 24 hours a day operation, no need to stop. This kind of continuous process rubber tyre recycling plant not only avoids the waste tire, waste plastic to the environment pollution, simultaneously produces the fuel oil, which can alleviate the energy crisis. So many investors began to pay attention to this opportunity.

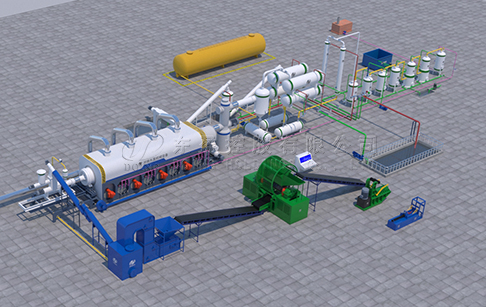

Continuous process rubber tyre recycling plant

Continuous process rubber tyre recycling plant

The continuous process rubber tyre recycling plant not only can handle 10 to 100 tons of waste tires per day, but also feed in one side and dischage in another side. So the work efficiency of the continuous process rubber tyre recycling plant is very high. And this continuous process rubber tyre recycling plant can be also used to pyrolyze waste plastics, oil sludge, rubber, medical waste. To a large extent, the continuous process rubber tyre recycling plant can save a lot of operating costs for us. That’s because it has small size, small floor area, simple operation, less operator, etc.

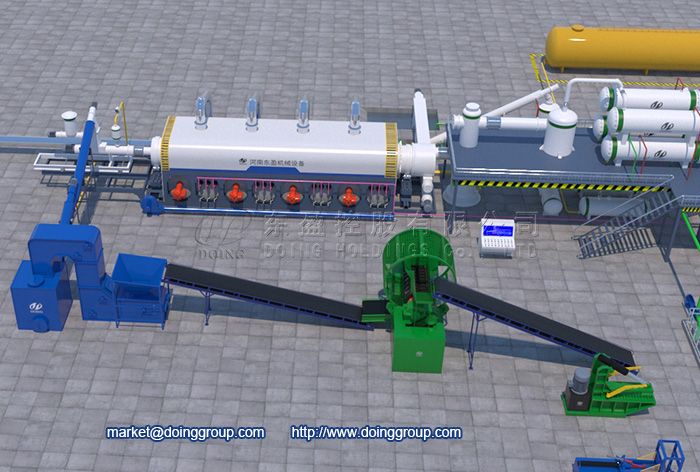

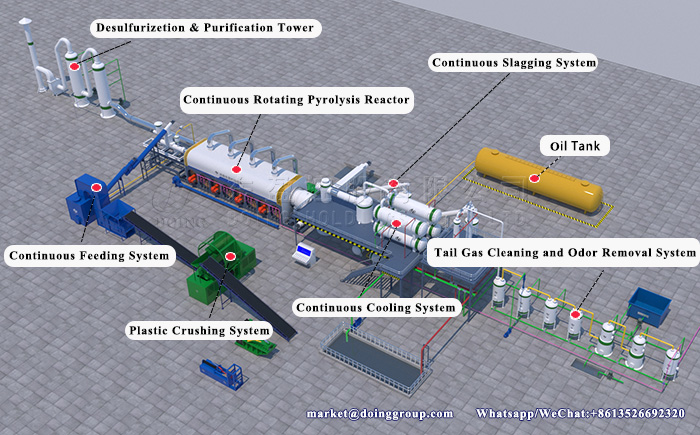

Main parts of DOING continuous process rubber tyre recycling plant

A complete set of continuous process rubber tyre recycling plant is mainly composed of many parts. They work together to ensure the normal operation of the plant. These parts are tyre shredder, continuous feeding system, continuous rotating pyrolysis reactor, continuous slagging system, continuous cooling system, continuous tail gas cleaning and odor removal system, desulfurizetion & purification tower, etc.

DOING continuous process rubber tyre recycling plant main parts

DOING continuous process rubber tyre recycling plant main parts

Advantages of continuous process rubber tyre recycling plant

1. Fully automatic with low labour cost

DOING continuous process rubber tyre recycling plant is controled by PLC system with automatic feeding and discharge system, which only need 2-3 worker to operate the PLC or computer.

2. Fully pyrolysis for high oil output

DOING continuous process rubber tyre recycling plant adopts accurate calculated pyrolysis system which can make fully pyrolysis of waste tires, thus to get high oil output.

3. Big capacity

Due to continuous feeding and discharge system, and unique pyrolysis reactor design, DOING continuous process rubber tyre recycling plant can process at least 10 tons waste tires per day, up to 100T/D.

4. Internal rotating for conitnuous operation

For external rotating system, you have to change the sealing material every three days, thus cannot achieve the real sense of continuous process. But our continuous process rubber tyre recycling plant reactor adopts internal rotating method, which no need to worry about the sealing of the external rotating system.

5. Continuous working save time and energy

DOING continuous process rubber tyre recycling plant can operate 24 hours a day without interruption, saving time and heating fuel.

6. Long working life

During the continuous pyrolysis process, reactor heating is by indirect hot air heating, which will not damage reactor so much, thus to keep long usage life of the reactors. In addition, the hard steel wire already removed from waste tires before pyrolysis processs, thus no damage for the reactor which also prolongs the life of the reactor.Technical parameter of continuous process rubber tyre recycling plant

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

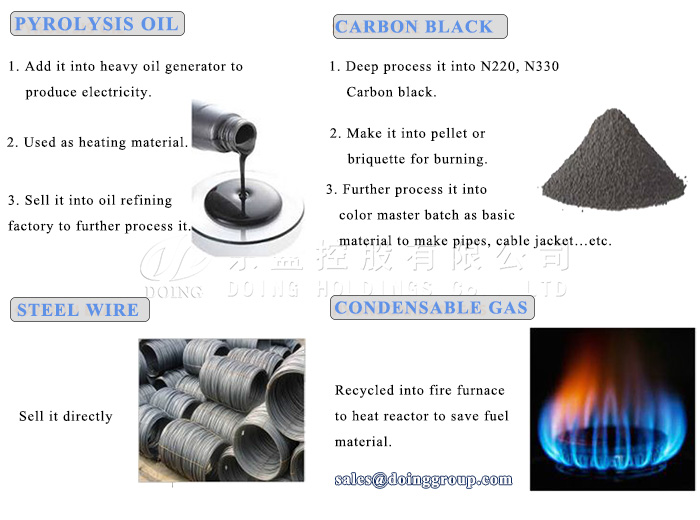

Final products and their applications of continuous process rubber tyre recycling plant

The final products of continuous process rubber tyre recycling plant are widely used for industrial and commercial purposes, as shown in the figure below.

Final products and their applications of continuous process rubber tyre recycling plant

Final products and their applications of continuous process rubber tyre recycling plant

Over the years, Doing company adheres to the business philosophy of “Quality First, Credit Foremost”, providing the best pre-sales and after-sales service and the most professional technical support to our customers, controlling the product quality strictly and constantly improving the machine design and production technology. We will be your best choice. Welcome to inquiry us.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?