What is the features of high quality used oil recycling machine?

Choosing a high quality used oil recycling machine is necessary if you want to obtain a high diesel yield. But do you know what kind of machine can reach these demands? Here I can list some of the features of a high quality used oil recycling machine.

First of all, high oil yield

High oil yield means more diesel from the same feedstock, and more benefit. In fact, the oil yield of used oil recycling machine is mainly affected by the condensing system and treatment process. DOING's used oil recycling machine adopts the most advanced three-stage cooling system to efficiently condense the oil gas during the condensing process, getting more diesel fuel. In 2019, DOING developed a new process using solid catalysts that could achieve an 85-90% oil yield.

Secondly, long running time and short slag discharge time

Some distillation units need to be processed in a batch to discharge slag, each operation is very time consuming. The used oil recycling plant designed by DOING can continuously process three batches of raw materials for one slag discharge, which greatly saves the operation of slag discharge and time for customers.

DOING used oil recycling plant

DOING used oil recycling plant

Thirdly, easy to clean up

A few years ago, horizontal distillation reactor was more common in the market. As you know, on the one hand, the horizontal reactor covers a large area, on the other hand, it has a matter in discharging residue. The asphalt is very sticky, but when it cools down, it becomes very difficult to clean up. Therefore, DOING adopt vertical design which is both convenient to discharge residue and can avoid hurting workers when discharging. It is specially designed to run more reliably and occupy less floor space.

Vertical design distillation reactor

Vertical design distillation reactor

Fourth, high efficiency

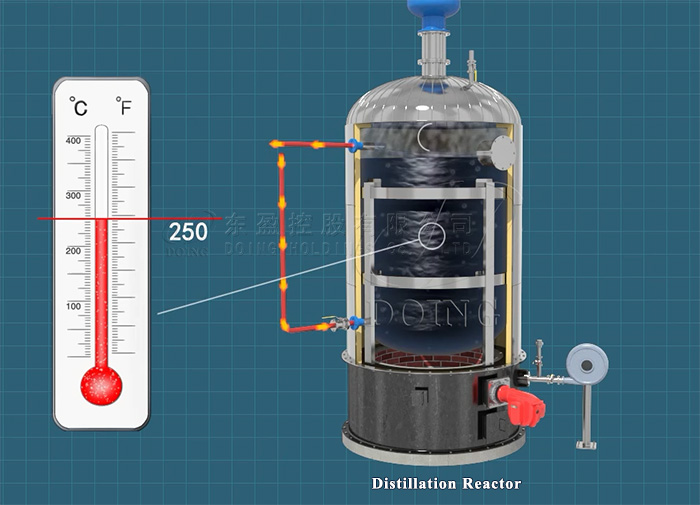

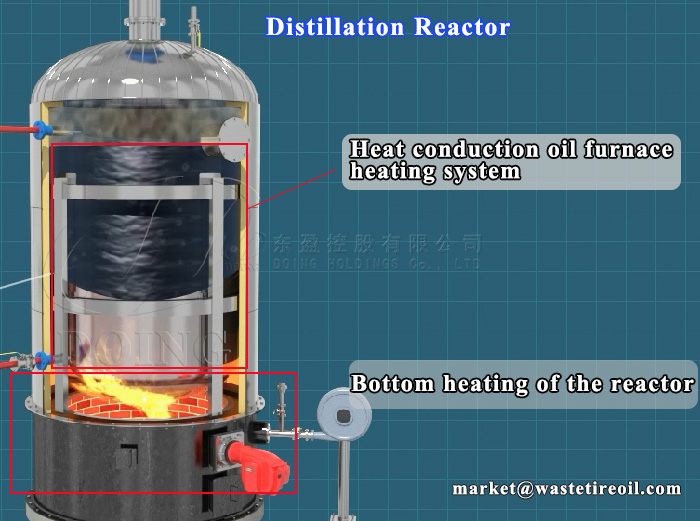

Some distillation machine are slow in processing and take several days to process in one batch, which consumes a lot of fuel and wastes a lot of customer time. Therefore, high efficiency is also one of the feature of high quality used oil recycling plant. The newly designed used oil recycling plant of DOING Company adopts the design mode of double heating. The heating time can be greatly saved and the efficiency of the whole equipment can be improved by using heat conduction oil and heating at the bottom of the distillation reactor. In this way, you can not only save the heating fuel, but also speed up the refining process, thus saving time.

Double heating

Double heating

After reviewing features of a high quality used oil recycling machine, I believe you can have more ideas about it. If you want to know more about our unique distillation machine and its quotation, please contact us without any hesitation, we will be willing to guide your installation.

PREV:What is the used motor oil recycling process of DOING distillation machine?

PREV:What is the used motor oil recycling process of DOING distillation machine?

NEXT:What is the profit of recycling 1 ton waste oil by waste oil distillation machine?

NEXT:What is the profit of recycling 1 ton waste oil by waste oil distillation machine?

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated