Used rubber recycling project report on pyrolysis plant

Why we need to dispose the used rubber?

With auto-industry growing strongly, 50%-55% raw rubber are used for tire manufacturing every year. Auto should change rubber every 30,000-50,000 km, in this way, 17 million tons used rubber produced in one year. Used rubber is refractory and needs hundreds of years before not affecting plants growth in the earth. It takes up quantities offarmland, breeding some diseases (dengue fever etc), destroys vegetation. If used for fuel or burned, no plants will grow in surrounding field. Thus to figure out an efficient and environmental way to dispose the used rubber is such important for the green world.

How to find a green and benefit way to process used rubber?

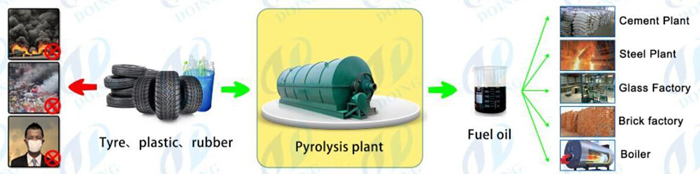

To achieve a green way for processing the used rubber, we developed the used rubber recycling pyrolysis plant for dealing with the used rubber. This way not only can make disposal for the used rubber, you also can get valuable products, like fuel oil, carbon black and steel wire for all kinds of commercial use. It' s a low investment but high benefit project.

Different ways to deal with the used rubber

What products you can get from the used rubber pyrolysis process?

How to deal with the final products made from used rubber pyrolysis process?

--- Fuel oil

Fuel oil application

This oil product is a kind of crude fuel oil, which can be used for industrial heating and in any fuel needed industrial factories, such as cement plant, steel mill, glass factory, brick factory, boiler used factory, etc. Or can be refined to diesel, directly used in diesel burners, generators, heavy trucks, agricultural machinery, and mix with normal diesel used for cars.

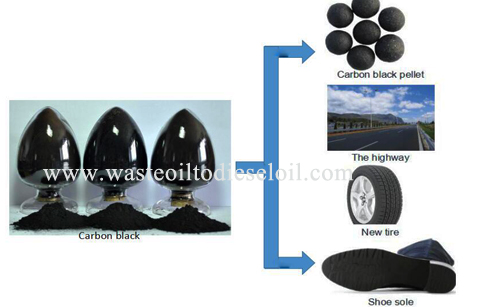

--- Carbon black

Carbon black application

Carbon black produced from this system is crude powdery material, which can be directly sold to cement factory mix with cement. Or made into briquettes used for heating, just like coal. Or grinded into fine powder used for making paint and printing ink.

--- Steel wire

Scrap steel wire can be directly sold to iron recycling station or steel mill for further treatment.

What other waste can be processed by the waste rubber recycling pyrolysis plant?

Except used rubber, this used rubber recycling pyrolysis plant also can be applicable to waste plastics or tyres.The final products are as below:

- From tires: fuel oil, carbon black and steel wire

- From plastics and rubbers: fuel oil, carbon black.

What' s the working principle of the used rubber recycling pyrolysis plant process?

Working principle: under high temperature heating, the solid materials (tyre/plastic/rubber) will pyrolyse to make oil gas come out, then go through water cooling system to become liquid oil. After oil gas come out completely, the residues will be carbon black and steel wire.

How to make profit analysis of the used rubber recycling project report on pyrolysis plant?

Here I have the profit analysis made by our Macedonia customer.

Below please check it for your reference. (Note: This analysis was made in 2012, the statistics are not new.)

| Profit analysis from the Macedonia customer(10T/D capacity) | ||

| Cost for one batch | ||

| No. | Item | Cost of each batch |

| 1 | 10 tons of waste tire | 10T*USD 42.5/T=USD 425 |

| 2 | 0.4 tons of coal | 0.4T*USD 70/T=USD 28 |

| 3 | Electricity and water | 244kwh*USD 0.26=USD63.44 |

| 4 | Workers | 4*USD 15=USD 60 |

| Total cost | USD 576.44 | |

| Income for one batch | ||

| 1 | Crude oil | 4.5T*USD 960=USD 4,320 |

| 2 | Steel wire | 10T*15%*USD 350/T=USD 525 |

| 3 | Carbon black | 3T*USD 20/T=USD 60 |

| Total income | USD 4,905 | |

| Total Profit | ||

| 1 | Daily profit | USD 4,328.56 |

| 2 | Month profit | USD 4328.56*25 days=USD 108,214 |

| 3 | Annual profit | USD 108,214*10month=USD 1,082,140 |

How to choose the use rubber recycling pyrolyis plant?

Since this recycling pyrolysis plant is similar as pressure vessel, which requires high standard quality control and safety measures. When you are ready to buy the plants, there are several important points that you need to pay more attention to:

--- Quality control

--- Safety measures

--- Environmental protection measures

--- Supplier experience

How is DOING’s experience?

We DOING Company as a leading company for manufacturing and supplying waste tire and plastic recycling machinery has specialized in this field for almost 10 years, 4 years for domestic market, 6 years for international trade.

By now, we have installed hundreds of machines in more than 30 countries all over the world:

Africa: Egypt, Nigeria, Sudan, Ethiopia, Congo, Uganda;

Europe: Romania, Poland, Italy, Macedonia, Albania, Turkey, Estonia;

Asia: Malaysia, Pakistan, India, Thailand, Iran, Bangladesh, Lebanon, Jordan, UAE;

America: Mexico, Ecuador, Haiti, Guatemala, Aruba, Panama, Jamaica, Colombia.

And we have very professional engineers which can sent to your site for machine installation, commissioning and training your workers.

How is the after-sale service?

--- Delivery time - It will be 10-15 days after we receive the deposit.

--- The installation period for one set machine is about 20-30days.

--- During the installation period, buyer should pays $60.00 per day to our engineer and the accommodation ; And buyer should take charge of the round trip air tickets for our engineer fly to your country.

--- Warranty: 1 year for free, except man-made damage.

Is DOING the manufacturer?

DOING factory

Waste recycling pyrolysis plants project cases:

DOING waste recycling pyrolysis plants installated in many counties

If you want to know more information about the waste recycling pyrolysis plants,welcome you come to our factory for a visiting or leave your message.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia

-

15 TPD used tyre pyrolysis machine produced fuel oil in Brazil

-

Waste tire to diesel plant project installed in South Africa