How to convert pyrolysis oil to diesel?

Waste tire/plastic pyrolysis plant can convert waste tire/plastic into pyrolysis fuel oil. It not only solves the tire&plastic pollution problem, but also creates considerable social and economical benefits. The pyrolysis oil is a heating fuel can be used in many industries. But it has much higher profit value to further process pyrolysis oil into diesel. Then how to convert pyrolysis oil to diesel? The pyrolysis oil is just like waste oil, and can be distilled by plastic oil to diesel distillation plant.

Convert pyrolysis oil into diesel by pyrolysis oil to diesel distillation plant

Convert pyrolysis oil into diesel by pyrolysis oil to diesel distillation plant

Pyrolysis oil to diesel distillation plant researched &developed by DOING GROUP adopts latest design and mature technology can convert tire pyrolysis oil, plastic pyrolysis oil and used engine oil into 80%-85% diesel and asphalt.

The main steps of converting pyrolysis oil to diesel

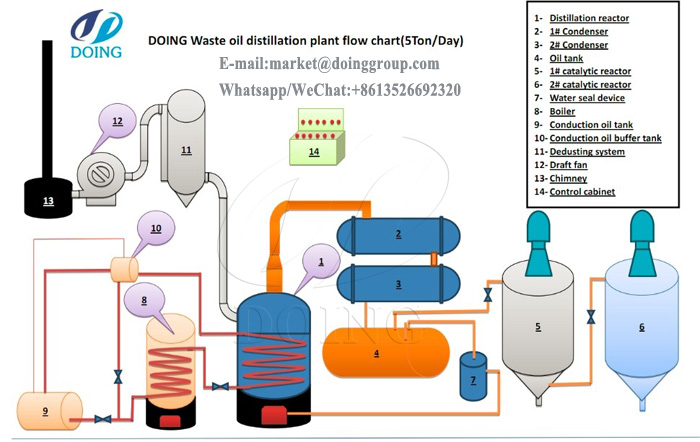

The flow chart of pyrolysis oil to diesel distillation plant

The flow chart of pyrolysis oil to diesel distillation plant

1. Distillation

Pump the pyrolysis oil into distillation reactor and start indirect heating with fast heating system, which can make sure all the pyrolysis oil get enough and even heat efficiently. Besides, indirect heating can prolong the reactor’s service life.

2. Oil gas purification &Catalyst reaction

when heated with a certain temperature, the pyrolysis oil will be converted into oil gas. Then oil gas enter into buffer chamber and catalytic tower for purification, decolorization and deodorization.

3. Cooling

The purified oil gas will go to horizontal condensing system. After cooling it is converted to diesel.

4. Further purification

To improve the diesel quality, we can further purify the diesel with our purification system.

5. Slagging asphalt

It’s very easy to discharge asphalt with vertical type distillation reactor and you can slag once after 3batches processing.

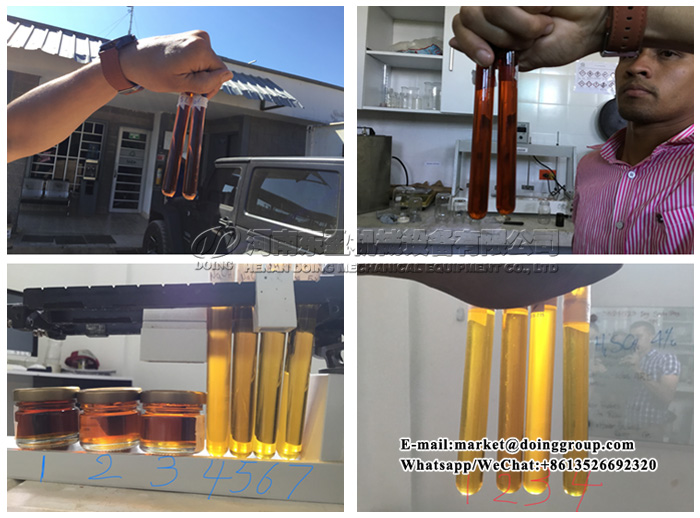

Project case picture display

The diesel from pyrolysis oil to diesel distillation plant

The diesel from pyrolysis oil to diesel distillation plant

The distillation plant designed based on this principle has been sold to more than 70 countries and regions in the world. The above picture shows the diesel produced by pyrolysis oil to diesel distillation plant in Colombia.

The features of DONG pyrolysis oil to diesel distillation plant:

1. Safe

There are special safety devices to ensure machine’s safe running for our pyrolysis oil to diesel distillation plant.

2. Environmental protection

we have professional gas scrubbing system and odor removal device can make sure no emission pollution.

3. High efficiency and energy saving

Vertical oil distillation reactor design is very convenient for asphalt discharging. Indirect heating make all oil gas get even heat thus shorten the heating time which is energy saving.

If you also want to convert pyrolysis oil to diesel, please feel easy to contact us for more information. Our professional project manager will give you a detailed introduction.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated