Waste plastic to diesel recycling plant

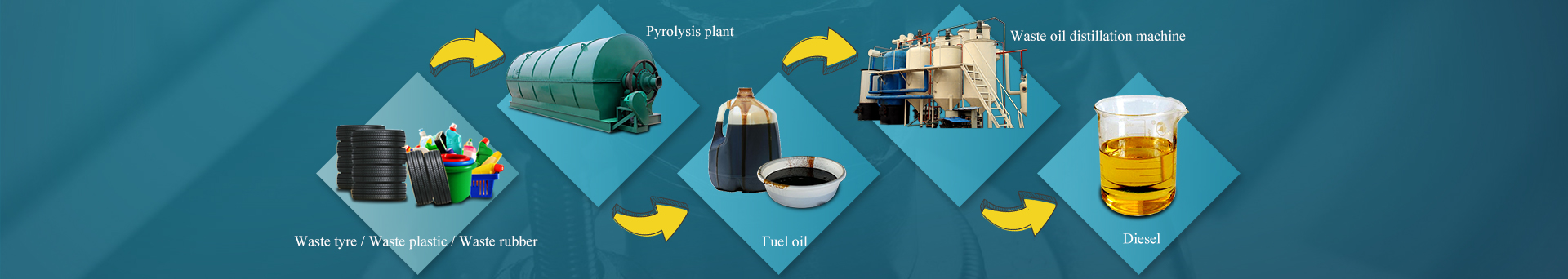

Waste plastics can be recycled into diesel oil, carbon black and liquefied petroleum gas by waste plastic to diesel recycling plant.

Waste plastic to diesel recycling plant installed

Waste plastic to diesel recycling plant installed

The main working process of waste plastic to diesel recycling plant

1. Crush and disinfect the collected medical waste rubber and plastic, and then kill bacteria and viruses in the waste rubber and plastic through microwave equipment.

2. In the process of conveying waste rubber and plastic, it is processed at high temperature to remove the harmful gases in rubber and plastic, which can be reacted with lye to generate salt and water;

3. Pyrolyze the molten material which has removed harmful gas at high temperature and atmospheric pressure to generate pyrolysis gas and carbon black, and the carbon black can be discharged by the carbon black discharge device;

4. Feed the pyrolysis gas into the catalytic tower for catalytic cracking, and generate oil vapor and mixed oil gas of liquefied petroleum gas;

5. Separate the mixture of oil gas into light oil and heavy oil by the fractionation column, and then cool oil gas into liquid oil by the condensation system and collect liquid separately;

6. Press non-condensable but combustible gas into liquefied gas by the compressor into the liquefaction device and load into the storage tank.

The customer is visiting waste plastic to diesel recycling plant

The customer is visiting waste plastic to diesel recycling plant

Advantages of waste plastic to diesel recycling plant

1. The whole set of waste plastic to diesel recycling plant adopts automatic PLC control system, which can realize the intelligent management of the whole process of waste plastics to diesel recycling plant by computer through the parameter setting of the control system, such as material transportation speed, temperature and pressure control during equipment operation.

2. We can use the Internet to achieve real-time monitoring of waste plastic to diesel recycling plant.

3. In the process of processing medical waste rubber plastics from waste plastic to diesel recycling plant, there is no harmful gas, liquid and solid material emission except carbon dioxide, which can achieve no environmental pollution.

The final products of waste plastic to diesel recycling plant

1. Diesel; 2. Gasoline; 3. Heavy oil; 4. Carbon black.

The final product of waste plastic to diesel recycling plant

The final product of waste plastic to diesel recycling plant

Waste plastic to diesel recycling plant can do the final harmless treatment to the non-renewable medical waste rubber plastics, and convert the chemical energy contained in it into fuel oil, carbon black and liquefied petroleum gas as industrial resources for recycling. Waste plastic to diesel recycling plant will be in the medical waste rubber plastic recycling play a huge role.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?