Waste Tyre Recycling Pyrolysis Plant

Here waste tyre recycling plant is refer to tyre pyrolysis plant which is mainly used to recycle the waste tyres into fuel oil, carbon black, syn-gas. Meanwhile, it can bring great benefits for investors. Currently, DOING has successfully exported waste tyre recycling plant to many countries, such as the Malaysia, Korea, India, Vietnam, USA, Poland, Australia, Indonesia, Brazil, Mexico, Nigeria, South Africa, Indonesia, Turkey, etc. Below are some of our successful cases.

DOING waste tyre recycling plant successful cases

Hot Product –Waste tyre recycling plant

Now DOING company has 3 types of waste tyre recycling plant for sale. They are respectively small tyre pyrolysis plant, batch tyre pyrolysis plant, continuous tyre pyrolysis plant. The small type is suitable for testing the yield of raw materials or the quality of equipment. Batch tyre pyrolysis plant is suitable for general handling capacity, moderate investment amount, continuous tyre pyrolysis plant is suitable for mass production, and need high investment amount. Of course, the greater the capacity of the waste tyre recycling plant, the greater the benefits. Investors can choose according to their actual situation.

3 types of waste tyre recycling plant for sale

3 types of waste tyre recycling plant for sale

Main part of waste tyre recycling plant

1. Pyrolysis reactor

The material of our pyrolysis reactor can be Q245R, Q345R boiler plate or 304 and 304 stainless. The thickness of the whole reactor plate is 16mm. Our pyrolysis reactor is manufactured exactly according to the standard of pressure vessel which can withstand high pressure and high temperature.The welding of our pyrolysis reactor adopt 3-step welding process, spot welding first, then make a groove like the one showed in the right picture for better auto-welding.

Pyrolysis reactor of waste tyre recycling plant

Pyrolysis reactor of waste tyre recycling plant

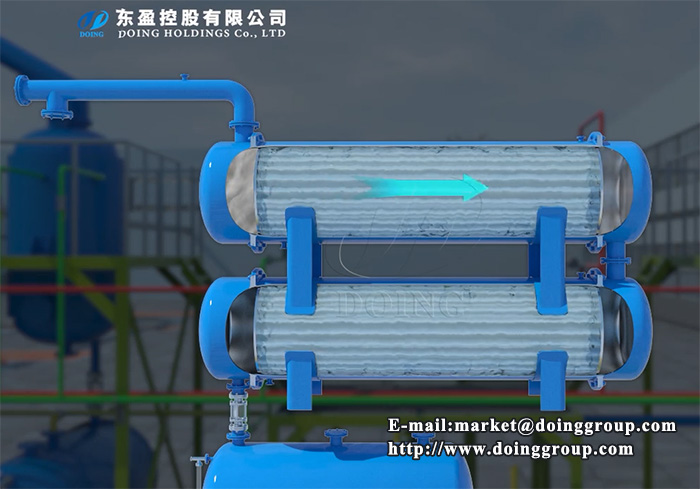

2. Condenser system

Waste tyre recycling plant has a condenser system to cool the oil gas into liquid oil. DOING waste tyre recycling plant adopts column tube condensation, which is the most commonly used condenser with the best effect. It can ensure sufficient cooling of oil gas and high oil yield.

Condenser system of waste tyre recycling plant

Condenser system of waste tyre recycling plant

3. Discharge System & Dedusting System

Both the small recycling pyrolysis machine and continuous tyre recycling pyrolysis plant are equipped with a fully sealed discharge system. It can greatly reduce fly ash and also improve safety. In additon, DOING batch tyre pyrolysis plant and continuous tyre pyrolysis plant are equipped with the tail gas deodorization device and dedusting system to remove sulfur components. The whole working process runs under the condition of no odors, no smoke, and it has good security and environmental protection.

Tail gas deodorization device and dedusting system

Tail gas deodorization device and dedusting system

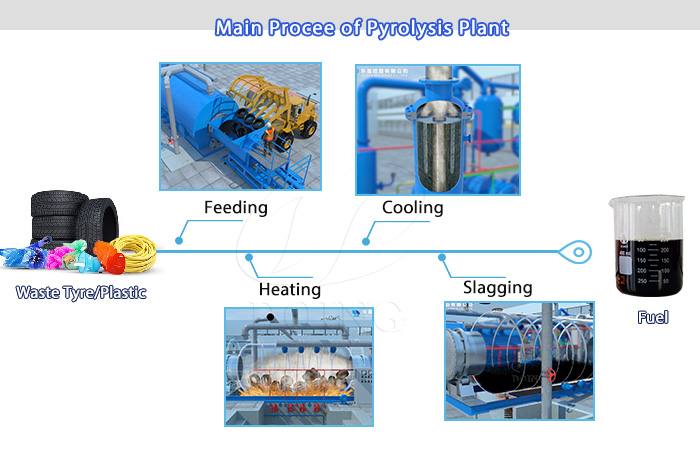

Waste tyre recycling process description

1. Put waste tyres into pyrolysis reactor by auto-feeder, then heat the reactor with any one of the following fuel materials: coal, wood, natural gas, oil. Do not stop heating the reactor, when the temperature reaches nearly 250 degree Celsius, waste tyre will be transferred to oil gas.

2. The liquid oil will be cooled by condenser from oil gas and then collected by oil tank.

3. The exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

4. Smoke produced by processing the tyres can achieve national emission standard through dual desulfurization and dusting removal device.

5. After you get oil, the temperature will be low, at this time, carbon black will be discharged automatically.

6. Last, when the temperature falls to 100 degree Celsius, worker could put steel wire hook to reactor to take steel wire out. After all these steps, you can start another batch.

Main process of waste tyre recycling plant

Main process of waste tyre recycling plant

Technical parameter of waste tyres recycling plant

| Technical parameter of waste tyres recycling plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-10 | DY-1-12 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 10 ton | 12 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2600×6600 | 2800×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 32T | 35T |

| Prepared by customer about Waste tyres recycling plant cost | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

The final products and their application

| Items | Picture | Application | Sales Market |

45% Pyrolysis oil |  |

1. Add it into heavy oil generator to produce electricity. 2. Used as heating material. 3. Sell it into oil refining factory to further process it. | Ceramic factory, glass factory, electric power factory, steel making factory, boiler factory…etc. |

30% Carbon black |  |

1. Deep process it into N220, N330 Carbon black. to make pipes, cable jacket…etc. | Coal briquette factory, plastic factory, cable factory, etc. |

15% Steel wire |  | Sell it directly | Iron and steel factory |

10% Waste gas |  | Recycled into fire furnace to heat reactor to save fuel material. | |

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?