Waste tyre to pyrolysis oil recycling plant

Waste tyre to pyrolysis oil recycling plant features:

Waste tyre to pyrolysis oil recycling plant

Pyrolysis is chemical reaction. This reaction involves molecular breakdown of larger molecules into smaller molecules in presence of heat. Pyrolysis is also known as thermal cracking, cracking, thermolysis, depolymerization, etc.

Tire pyrolysis is: the process of converting waste tires into industrial fuels like Tire Pyrolysis Oil, Carbon Black, Steel Wire and Hydrocarbon Gas.

Waste tyre to pyrolysis oil recycling plant

Our waste tyre to pyrolysis oil recycling plant can convert waste tyre into high grade fuel oil. Waste tyre are long chain polymers containing more than 50000 carbon atoms attached to each other in a cross linked or straight chainThough waste tyre to pyrolysis oil recycling plant, this long chain is broken down into smaller chain. The use of waste tyre to pyrolysis oil recycling plant turns waste materials into gases and liquids. The end products can be used in any standard diesel engine or generator with little or no modifications.

| Technical parameter of waste tyre to pyrolysis oil recycling plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyres/plastic/rubber | waste tyres/plastic/rubber | waste tyres/plastic/rubber |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about waste tyre to pyrolysis oil recycling plant | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

End products of waste tyre to pyrolysis oil recycling plant:

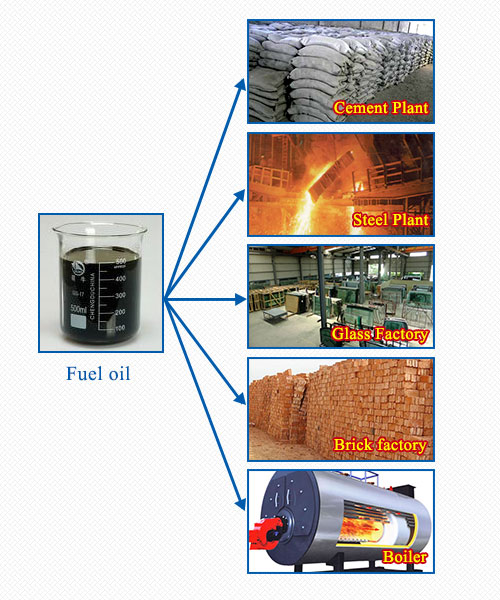

a.The usage of final production----pyrolysis oil

Pyrolysis oil application

Pyrolysis oil from waste tyre are used in below industries

A.Power plant factory

B.Glass factory

C.Cement factory

D.Ceramic factory

E.Aluminum factory

F.Boiler factory

G.Central heating factory

H.Painting factory

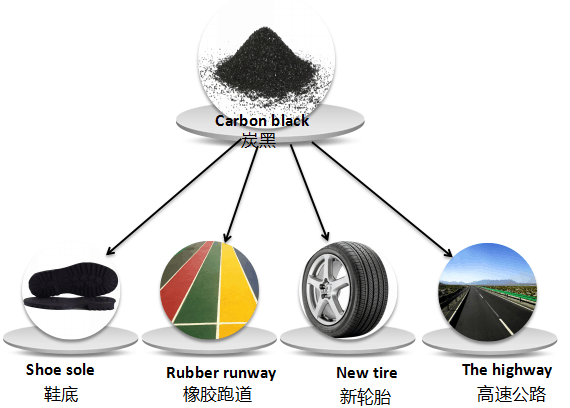

b.The usage of final production-----Carbon black

Carbon black from waste tyre are used in below industries

Carbon black application

A.EConveyor ban

C.Hose and doormat

D.Black nylon bag

E.Rubber additive

F.Automatic spare parts

G.Heat isolation

H.Black colorant in rubber materials

c.Steel wire:

A.Steel wire can be sold directly.

Fuel oil application

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?