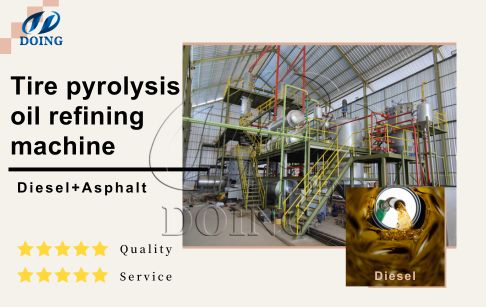

Tire pyrolysis oil refining machine

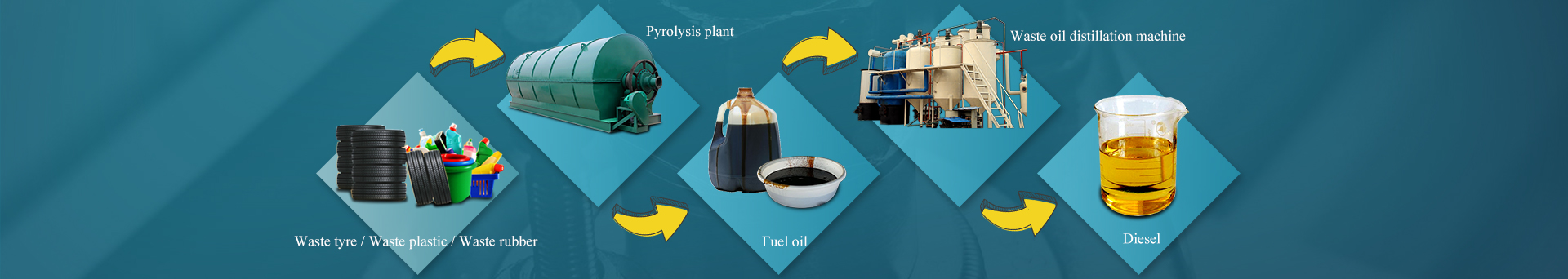

Tire pyrolysis oil is an end product extracted from the waste tire pyrolysis machine and is often used as heating fuels or generating electricity with heavy machinery. But if we use the tire pyrolysis oil refining machine to purify the tire pyrolysis oil, we can enlarge its applications and enhance its market value. This passage will have a brief introduction about DOING tire pyrolysis oil refining machine:

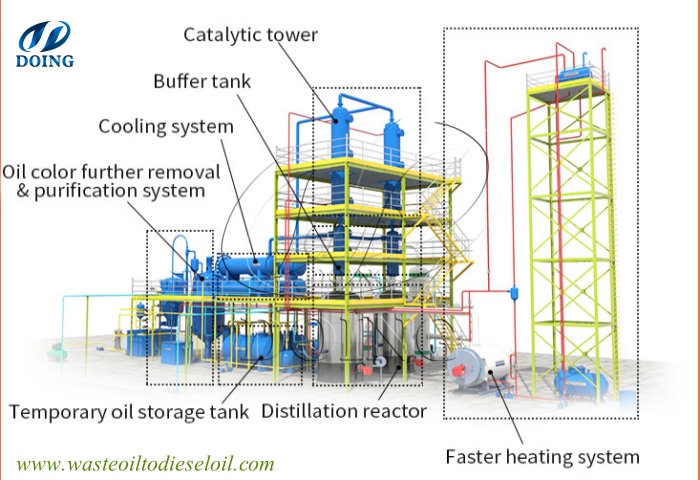

The main components of the tire pyrolysis oil refining machine include fast heating system, distillation reactor catalytic tower, buffer tank, cooling system, oil color further removal&purification system, temporary oil storage tank, safety system, environmental protection system, etc.

Components of DOING tire pyrolysis oil refining machine

Components of DOING tire pyrolysis oil refining machine

DOING tire pyrolysis oil refining machine has a compact overall structure and scientific and reasonable equipment configuration, which can realize stable operation and can improve work efficiency, reduce energy consumption, and realize resource recycling and reuse.

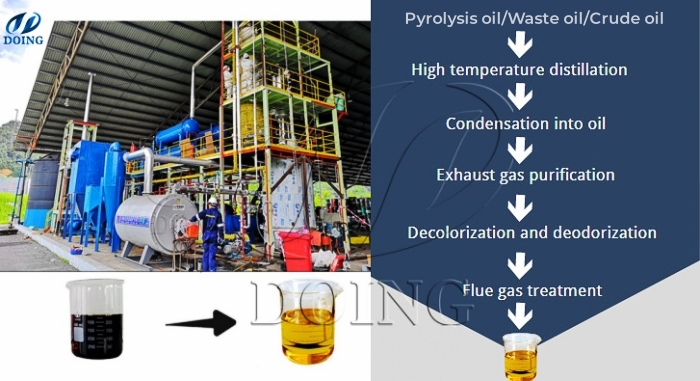

By using a high-temperature distillation for tire pyrolysis oil, the impurities in the oil are distilled off, and the filtered light oil vapor increases in heat, and impurities in the pyrolysis oil fall into the furnace.

Light oil and gas passes through a multi-stage heating system, is filtered, enters a cooling system, is then liquefied, passes through a water separator, and flows into a light oil tank.

Work flow of DOING tire pyrolysis oil refining machine

Work flow of DOING tire pyrolysis oil refining machine

After acid and alkali washing or solid catalyst purifying, clean and transparent diesel oil can be obtained. The average diesel yield is 80%-85%.

Finally, the residue in the furnace is discharged from the furnace. It is a substance that functions like asphalt. The approximate yield of bitumen is 15%-20%.

| Two types of DOING Tire pyrolysis oil refining machine | ||

| Type | Latest design type | Common design type |

| Picture |  |  |

| Processing capacity | DY-5-14TPD | DY-0.1-14TPD |

| Catalyst system | Solid catalyst | Acid and alkali catalysts |

| Heat method | Indirect heating | |

| Raw material | Waste oil, crude oil, pyrolysis oil, used engine motor oil, etc. | |

| Heating fuel | Fuel oil, natural gas, coal, wood, etc. | |

| Reactor structure | Vertical structure | |

| Cooling type | Circulating water cooling | |

| Final products | Diesel, asphalt | |

Feedstock: in addition to the tire pyrolysis oil, other types of pyrolysis oil, waste motor engine oil, crude oil, used lube oil all can be used for the tire oil refining machine;

Final products:

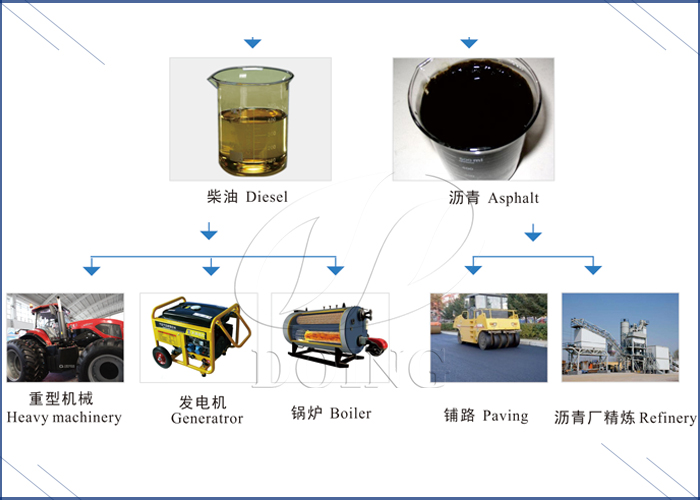

Diesel: Mainly used for heavy machinery, generator power oil, and boiler heating combustion oil.

Applications of obtained diesel and asphalt

Applications of obtained diesel and asphalt

Asphalt: Mainly used for direct paving, or sent to asphalt refineries.

As an reliable and experienced manufacturer and supplier off tire pyrolysis oil refining machine, DOING can provide a series of services to help you successfully carry out the project, if you have the investment plan, DOING will be the best choice for you!

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?