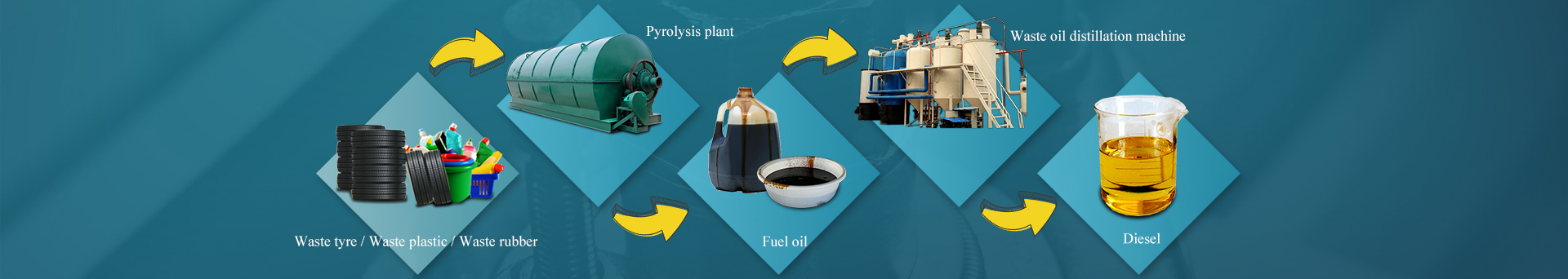

Used engine oil to diesel recycling system

Used engine oil

Used engine oil to diesel recycling system

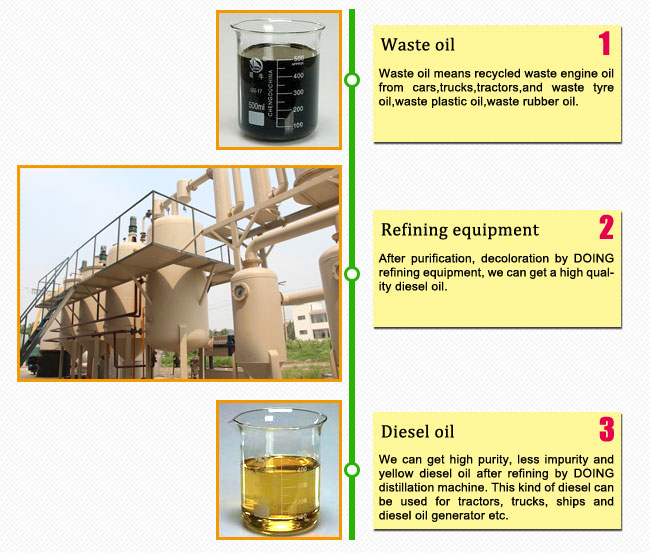

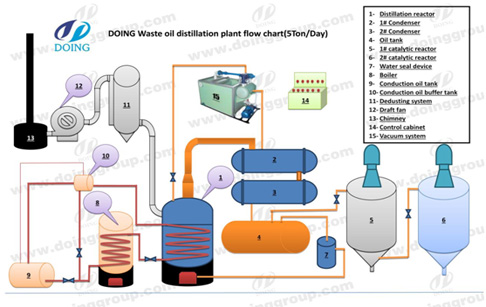

2. Heating system works to heat waste oil over 170℃

3. Distillation oil gas produced and cooling down to pure distillation oil by condensers

4. After distillation, the distillation oil is pumped into odor-removal tank where catalysts used to remove the smell

5. Then oil go into color-removal tank for de-coloring with the special catalysts

6. Finally, you can get about 85% pure diesel oil.

1. Safety devices such as alarming device, pressure gauge, safety valve. If there is some pressure in the reactor, the alarming device will ring and even no workers hear it, it does not matter as we have the reducing pressure device automatically.

2. Vacuum system can ensure the plant running in a safety condition. Make the whole refining processing be on a normal pressure to avoid accident.

| Technical parameter of used engine oil to diesel recycling system | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | engine oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Diesel application of used engine oil to diesel recycling system

| Oil yield of different material: | ||

| No. | Name | Oil yield |

| 1 | Used oil | 85%-90% |

| 2 | Waste plastic oil | 95% |

| 3 | Waste engine oil | 85%-90% |

PREV:Crude oil to diesel refinery distillaion process plant

PREV:Crude oil to diesel refinery distillaion process plant

NEXT:Converting waste motor oil to diesel fuel refining plant

NEXT:Converting waste motor oil to diesel fuel refining plant

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia

-

15 TPD used tyre pyrolysis machine produced fuel oil in Brazil

-

Waste tire to diesel plant project installed in South Africa

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?