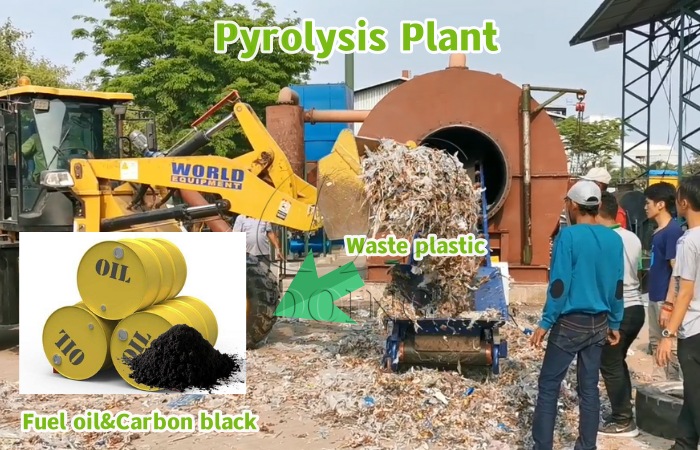

Can plastic be converted back to oil? How to make fuel oil from waste plastic?

Plastic is commonly found in household waste. Can plastic be recycled and converted into new energy sources? The answer is that plastics such as PP, PE, and PS can be converted back into fuel oil using pyrolysis machines, while PET and PVC cannot undergo pyrolysis.

Recycable plastic for pyrolysis into fuel oil

Recycable plastic for pyrolysis into fuel oil

This article introduces the process of making fuel oil from waste plastics using the DOING plastic pyrolysis machine.

The first step is feeding. The entire feeding process only requires two workers and takes approximately 1.5 to 2 hours to fill a reactor with a daily processing capacity of 12 tons. If an automatic feeder is not used, the entire feeding process will take 2-3 workers 3-4 hours to complete.

Auto feeder for waste plastic pyrolysis machine

Auto feeder for waste plastic pyrolysis machine

The second step is pyrolysis. After the feeding is completed, the burners need to be ignited to heat the plastic pyrolysis machine reactor. This will evaporate the water content in the waste plastic. The temperature will then gradually increase to 200 degrees Celsius. By controlling the burners to maintain the temperature between 230 and 260 degrees Celsius, the oil output stage is reached. Next is the constant temperature reaction stage, during which the temperature will decrease. It needs to be controlled to gradually increase until the oil output decreases. Finally, the temperature is raised to 150 degrees Celsius to ensure that the plastic pyrolysis fuel oil is fully extracted.

Plastic to fuel oil pyrolysis machine

Plastic to fuel oil pyrolysis machine

The third step is the condensation stage. DOING plastic pyrolysis machine includes a cooling system with four steps. It consists of two vertical condensers, one oil-water separator, two horizontal condensers, and two condensation towers. The first oil tank contains heavy oil that has been cooled down through the vertical condensers, while the oil in the second and third oil tanks will be of better quality. The two horizontal condensers have the largest cooling area and provide the best cooling effect, allowing for 80% - 90% of the oil to be cooled down. All condensers use circulating cooling water, achieving zero wastewater discharge. The uncondensed gas can be purified and used for heating the pyrolysis reactor.

Cooling system of plastic to fuel pyrolysis machine

Cooling system of plastic to fuel pyrolysis machine

Once the entire waste plastic to fuel pyrolysis process is completed, you can cool down the plastic pyrolysis machine and then remove the solid residues (carbon black) for sale.

If you are interested in converting waste plastic back into fuel oil, please feel free to send us your inquiry about our waste plastic pyrolysis machine. We Henan Doing Company offer different scales of plastic pyrolysis machines for sale at factory prices, and all-around technical services like solution customization, plant drawing, installation guidance will be provided.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated