What are the benefits of tyre pyrolysis machine

Pyrolysis machine has become one popular method for solid waste management solution such as tire, rubber, plastics for its various benefits:

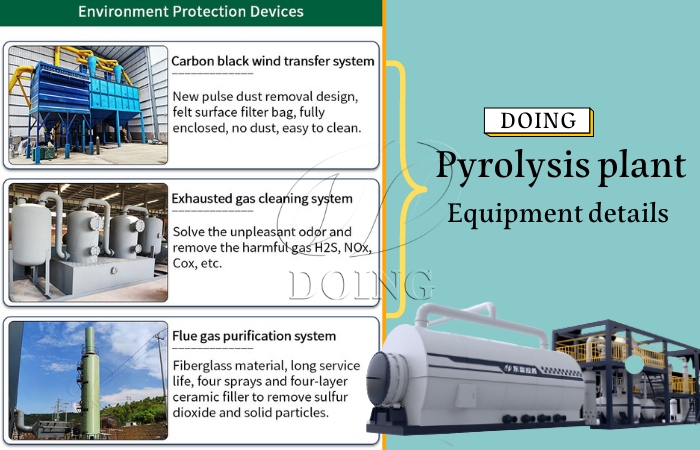

First, it’s environmental protection. Tyre pyrolysis machines can effectively reduce the amount of waste tyres in the environment in an environmentally friendly method, reducing the harm to air, soil and water compared with traditional landfilling and burning. Additionally, tyre pyrolysis machines will be equipped with some environmental protection systems, which can fully purify the exhaust gas to meet the emission standards.

Environmental protection systems of DOING pyrolysis machine

Environmental protection systems of DOING pyrolysis machine

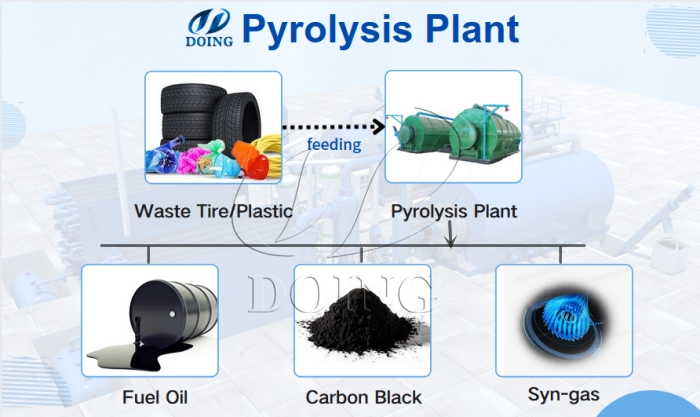

Second, it’s energy conservation and emission reduction. Tyre pyrolysis machines can convert waste tyres into energy-saving materials like fuel oil, carbon black and combustible gas, which can be used as energy sources or raw materials in industry, effectively reducing the consumption of traditional energy resources and reducing emissions. In addition, tyre pyrolysis can also reduce the need for landfill and reduce the cost of waste treatment.

Final products obtained from pyrolysis machine

Final products obtained from pyrolysis machine

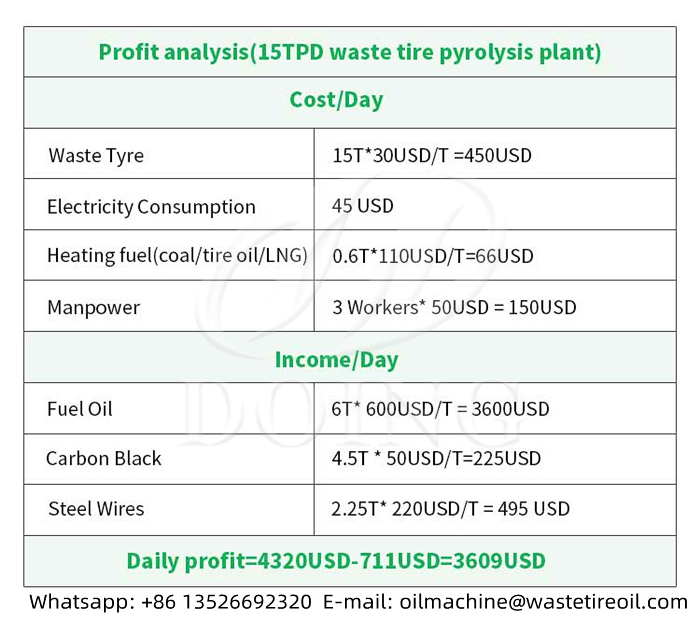

Third, we can obtain huge profits from tyre pyrolysis machines. As we all know, the obtained fuel oil, carbon black and combustible gas from tyre pyrolysis machines all have wide applications and large market prospects. According to the real feedback of our customers and the market survey, about half a year we can get our money back. The following is a profit analysis of DOING 15TPD tyre pyrolysis machine(the profits will vary from the market):

Profits analysis of DOING 15TPD waste tyre pyrolysis machine

Profits analysis of DOING 15TPD waste tyre pyrolysis machine

In a word, tyre pyrolysis machines have many benefits and tyre pyrolysis machine projects have become hot investments. Then how to select a suitable tyre pyrolysis machine to begin the investment? Here I'd like to introduce one tyre pyrolysis machine manufacturer and supplier-DOING Group:

DOING has been involved in tyre pyrolysis machine manufacturing for over 13 years, and we also have abundant experience in scheme customization, tyre pyrolysis machine installation guidance, technical training and other aspects, which can provide the one-stop service to help you begin the tyre pyrolysis machine investment.

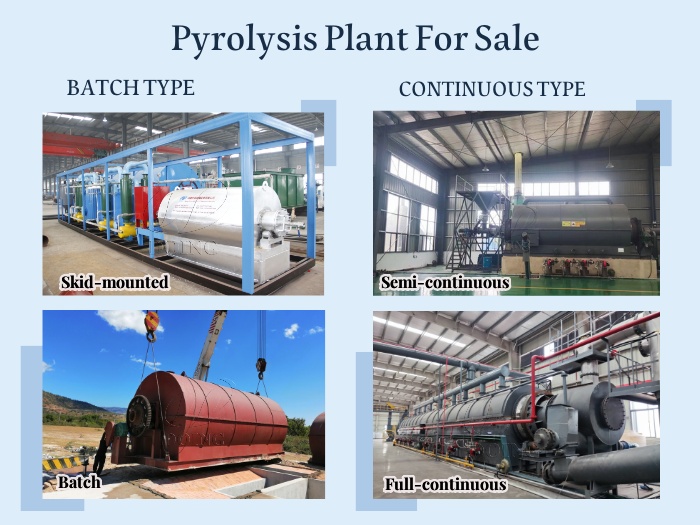

Projects of DOING pyrolysis machines

Projects of DOING pyrolysis machines

And as for the tyre pyrolysis machine, DOING can provide tyre pyrolysis machines with different processing capacities to meet different customer processing requirements. And there are different machine types to choose: skid-mounted type, batch type and continuous type. Among them, the fully continuous tyre pyrolysis machine has the highest configurations, which can realize 24/7hours running without stopping. For small scale tyre pyrolysis machines, such as 100kg, 500kg, 1 ton and 2 ton processing capacities, are mainly used for preliminary testing to show to investors for applying the larger projects. Of course, if you have other requirements, DOING can also provide customization services for you.

Four types of DOING pyrolysis machines

Four types of DOING pyrolysis machines

If you want to know more about the benefits of tyre pyrolysis machines or want to invest in the tyre pyrolysis machine business, please feel free to contact the DOING Group.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated