How to Optimize Oil Yield and Quality with Tire Pyrolysis oil Production Equipment?

Optimizing the oil yield and quality with tire pyrolysis oil production equipment can be carried out from the following aspects:

1. Optimize raw material selection:

Tire types and quality: Choose waste tires with higher rubber content and lighter wear as raw materials, such as large car and truck tires. The oil yield rate of these tires is usually higher. And we can select these waste tires with lower moisture, which can not only enhance pyrolysis efficiency to improve the oil yield and quality.

Pretreatment machine for waste tires

Pretreatment machine for waste tires

Pre-Treatment: Pre-treating the tires by cutting or shredding them into smaller pieces will improve the efficiency of the pyrolysis process. Smaller tire particles allow for more uniform heating, which can increase the yield and quality of the oil.

2. Reasonable control of pyrolysis process:

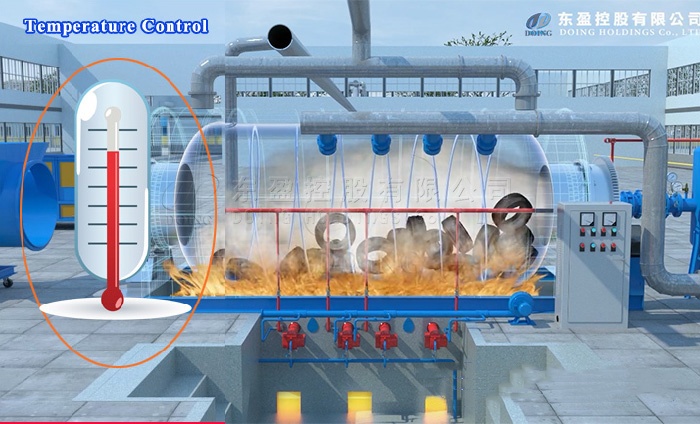

Pyrolysis temperature control: Pyrolysis temperature has a significant impact on oil yield and quality. If the temperature is too low, tire pyrolysis will be insufficient, and if the temperature is too high, a large amount of oil and gas will be generated in a short period of time, which affects the subsequent condensation efficiency and thus the oil yield and quality. The ideal cracking temperature range is 250-380°C, and it is recommended to increase the temperature slowly to maintain the best pyrolysis effect.

Temperature control for tire pyrolysis oil production equipment

Temperature control for tire pyrolysis oil production equipment

Pyrolysis time control: The residence time of waste tires in the pyrolysis machine will also affect the oil yield and quality. Generally, DOING tire pyrolysis oil production equipment will rotate at a fixed rate, which can be controlled based on the processed tires state and quantity, to ensure good pyrolysis efficiency.

3. Tire pyrolysis oil production equipment configurations:

Condensation system: Choose tire pyrolysis oil production equipment with efficient condensation systems, such as using a multi-stage condenser design to ensure adequate cooling of oil and gas and improve condensation efficiency and oil yield.

PLC control of tire pyrolysis oil production equipment

PLC control of tire pyrolysis oil production equipment

Highly intelligent control system: Improve the level of tire pyrolysis oil production equipment automation and intelligence with the fully automatic PLC control system and other intelligent systems, such as automatic feeding control, intelligent sorting, etc., to reduce manual intervention and improve production efficiency and accuracy.

4. Post-Treatment and Refining of Tire Pyrolysis Oil

The obtained tire pyrolysis oil is a kind of heavy oil, which can be used in cement plant, steel plant, glass plant, brick plant, boiler heating, ect. If you want to enhance the quality of the obtained tire pyrolysis oil, waste oil distillation machine is an effective method, which can improve the color and odor of the tire pyrolysis oil to get high quality diesel oil while enlarge applications and markets. The final diesel oil has good color and no bad smell, which can be used in diesel generator, ships, trucks, tractors, etc.

DOING waste oil distillation machine for sale

DOING waste oil distillation machine for sale

In addition to optimizing oil yield and quality with tire pyrolysis oil production equipment, we also need to consider the whole performance of the tire pyrolysis oil production equipment, such as environmental protection, safety working, etc. As a professional manufacturer and supplier of tire pyrolysis oil production equipment, DOING has abundant experience helping our customers to carry out the tire pyrolysis oil production equipment project. If you need more information, just feel free to contact us directly!

PREV:Can we use waste oil to produce fuel for mining and truck fleet?

PREV:Can we use waste oil to produce fuel for mining and truck fleet?

NEXT:How do you start a waste oil to diesel recycling plant step by step?

NEXT:How do you start a waste oil to diesel recycling plant step by step?

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia

-

15 TPD used tyre pyrolysis machine produced fuel oil in Brazil

-

Waste tire to diesel plant project installed in South Africa