What types of waste oil can be recycled into diesel by waste oil distillation plant?

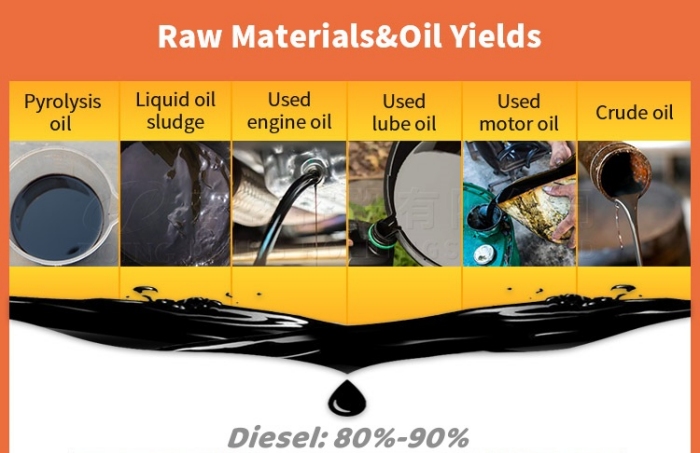

Waste oil distillation plant is a set of equipment that can recycle waste oil into diesel. DOING waste oil distillation plant can recycle at least six types of waste oil into diesel, including waste engine oil, waste lubricating oil, liquid oil sludge, waste motor oil, crude oil and waste tire/plastic pyrolysis oil.

Raw materials for waste oil to diesel distillation plant

Raw materials for waste oil to diesel distillation plant

Through distillation and refining process, the distilled diesel is usually light yellow and can be used in burners, generators, engines, trucks, engineering vehicles, agricultural machinery vehicles, etc. You can use it by yourself or sell it to other factories.

Applications of waste oil refinery final products

Applications of waste oil refinery final products

Are you planning to set up a waste oil distillation plant now? If yes, DOING can help you. We have more than 12 years of experience and a lot of professional information about projects, which can be given you any time. Such as the business plan, profit analysis, plant design, process drawings, etc.

If you are sure to start the waste oil distillation plant, the preparations in the early stage are very important. But more important is choosing suitable and good equipment.

Waste oil distillation plant installed by DOING Company

Waste oil distillation plant installed by DOING Company

In our DOING Company, there are two different technologies for DOING waste oil distillation plant. One is the use of chemicals to remove impurities and odor, and the other is the use of new catalysts to remove impurities and odor from waste oil. Their technology process is almost the same, includes distillation, condensation, decolorization and deodorization, and filtration, but the configuration is different.

Two kinds of waste oil distillation plants for sale

Two kinds of waste oil distillation plants for sale

The detailed introduction of waste oil to diesel refining process is as follows:

1. Distillation: To heat the waste oil to evaporate the oil gas and remove the impurities in the waste oil.

2. Condensation: To cool the oil gas into oil through the condensing system and circulating water.

3. Decolorization and Deodorization: To use the catalysts to remove the gum and waxy and odor from the cooled oil. This prevents the oil from changing color over time.

4. Filtration: If you want to get a cleaner, lighter yellow color, you can filter the diesel again with a filtration system, which is mainly used for decolorization.

Relatively speaking, if your budget is enough, we recommend the second kind of waste oil distillation plant -- new catalysts to remove impurities and odor from waste oil. It is with higher efficiency and more automatic working process, which can save time and labor costs. But if your budget is not very much, the first kind of waste oil distillation plant is more suitable, which is cost-effective.

Are you interested in our DOING waste oil distillation plant? Contact us and get free quotation or other information.

PREV:Can pyrolysis oil replace diesel to be used as an alternative fuel?

PREV:Can pyrolysis oil replace diesel to be used as an alternative fuel?

NEXT:What's the cost of pyrolysis oil to diesel distillation plant?

NEXT:What's the cost of pyrolysis oil to diesel distillation plant?

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated