How many types of waste oil refinery distillation machines are there for sale?

DOING Company has two different designs for our waste oil refinery distillation machines. One is the common waste oil refinery distillation machine, which needs to use the liquid catalyst. The other one is the new waste oil refinery distillation machine independently developed by our company, which uses the solid catalyst.

These two different waste oil refinery distillation machines have their own advantages and different working processes, which can meet the various requirements of clients.

1. The common waste oil refinery distillation machine

The common waste oil refinery distillation machines need to use acid and alkali as the catalysts. So for these customers who can get acid and alkali easily, such as in India and Africa, the common waste oil refinery distillation machine is a more popular choice. What's more, the common waste oil refinery distillation machine needs relatively less money to invest and is easy to install.

For the common waste oil refinery distillation machine, we need to heat the reactor to distillate the waste oil into oil gas and then the oil gas will be cooled into liquid oil. The liquid oil will be further refined by acid and alkali to remove the glue and wax, then you can get the diesel. This process will take about 8 hours, but you could operate distillation and washing at the same time, they don’t affect each other.

The common waste oil refinery distillation machine

The common waste oil refinery distillation machine

2. The new designed waste oil refinery distillation machine

The new designed waste oil refinery distillation machines use the solid catalyst, which can be bought from our company directly. And the new designed waste oil refinery distillation machines have a higher degree of automation and safety. It also costs less labor due to its high efficiency.

For the new designed waste oil refinery distillation machine, the catalyst tower is on the reactor directly. When the oil gases go through the catalyst tower, it will be recycled to diesel oil gas directly. After cooling down, we can get liquid oil, which can save a lot of operating work and labor costs.

The new designed waste oil refinery distillation machine

The new designed waste oil refinery distillation machine

However, the diesel from these two waste oil refinery distillation machines is of the same quality. They both can be used in the heavy machinery, generator and boiler.

Recommend: waste oil to diesel diatillation machine introduction

If you are interested in learning more about our waste oil refinery distillation machines or get more machine details and quotations, please contact us directly or leave a message.

PREV:What factors need to be considered when building a waste oil refinery plant?

PREV:What factors need to be considered when building a waste oil refinery plant?

NEXT:Which company supplies machines to turn plastic into diesel?

NEXT:Which company supplies machines to turn plastic into diesel?

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

-

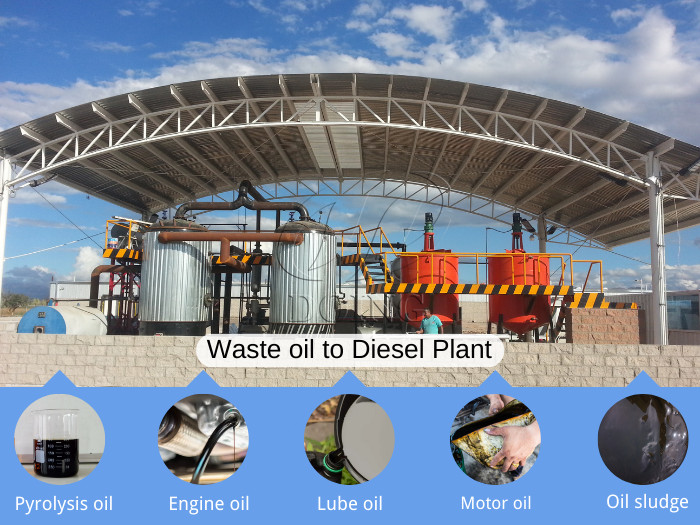

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia

-

15 TPD used tyre pyrolysis machine produced fuel oil in Brazil

-

Waste tire to diesel plant project installed in South Africa