What are the methods to convert plastic into fuel?

The problem of waste plastic recycling has become a global problem, and we urgently need to find ways to deal with waste plastic. And turning waste plastics into liquid oil as fuel oil is an environmental and profitable waste plastic recycling solution. Then what method can be convert waste plastics into fuel? I am writing an article to introduce it.

There are two kinds of fuel that can be obtained from waste plastic. One is pyrolysis fuel oil, the other is diesel fuel.

1. The method of converting plastic into pyrolysis fuel oil

DOING waste plastic pyrolysis machine can be used to get pyrolysis fuel oil from plastic. The plastic pyrolysis process is actually the thermal decomposition process of plastic polymers, that is, the long-chain polymers of carbon atoms (C-50,000 to C-2,00,000) in waste plastics are decomposed into smaller chains ( C-1 to C-4 and C-5 to C-23). Among them, C-5 to C-23 are pyrolysis fuel oil.

The process of converting plastic into fuel

The process of converting plastic into fuel

The pyrolysis process is very important because it is related to the final oil yield of the plastic. The process of our pyrolysis machine includes: feeding, high-temperature pyrolysis processes(plastic convert into oil-gas), cooling(oil-gas cooling into fuel oil and noncondensable gas), gas treatment and discharge, storage. Among them, the four-channel cooling systems ensures a high oil yield.

DOING has different types of pyrolysis machines that can convert kinds of plastics, such as PP, PE, ABS, etc.. Also, they can pyrolysis other solid waste, such as waste tires, rubber, oil sludge, etc..

2. The methods of converting plastic into diesel fuel

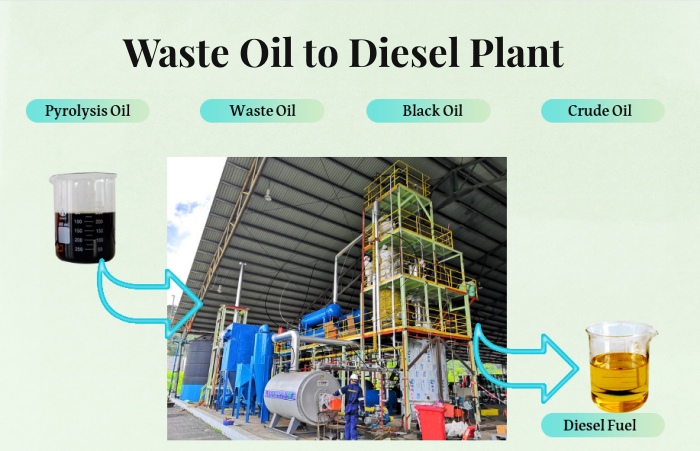

To get diesel from plastic, our solution available is through waste plastic pyrolysis machine and pyrolysis oil distillation plant.

After obtaining pyrolysis oil according to the pyrolysis process above, we just need to further refine it and diesel will be obtained. Then the pyrolysis oil is processed by distillation plant, which through heating, catalysis, distillation and clay decolorization to purify the pyrolysis oil into diesel fuel. Our distillation plant only loses 10% to 15% of the pyrolysis oil consumed, which means you will get more than 85% diesel fuel, and the diesel fuel is of high quality.

DOING pyrolysis oil distillation plant

DOING pyrolysis oil distillation plant

The above is an introduction to the method of converting waste plastics into fuel. Whether you want to buy machines to convert plastics to pyrolysis fuel oil or to buy machines to convert plastics to diesel fuel, you can contact us.

We are Henan Doing Group in China. We have been engaged in waste plastic to fuel machines for many years and have rich experience, and our pyrolysis machines and distillation plants have been installed and operated smoothly in more than 90 countries and regions. Besides, our machine will make your project more efficient and profitable. Our team will provide the best service for you. Welcome to consult and visit our factory!

PREV:How can we reuse waste oils?

PREV:How can we reuse waste oils?

NEXT:Applications of pyrolysis oil as fuel alternative obtained by pyrolysis plant

NEXT:Applications of pyrolysis oil as fuel alternative obtained by pyrolysis plant

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia

-

15 TPD used tyre pyrolysis machine produced fuel oil in Brazil

-

Waste tire to diesel plant project installed in South Africa