Waste plastic refining to diesel integrated plant

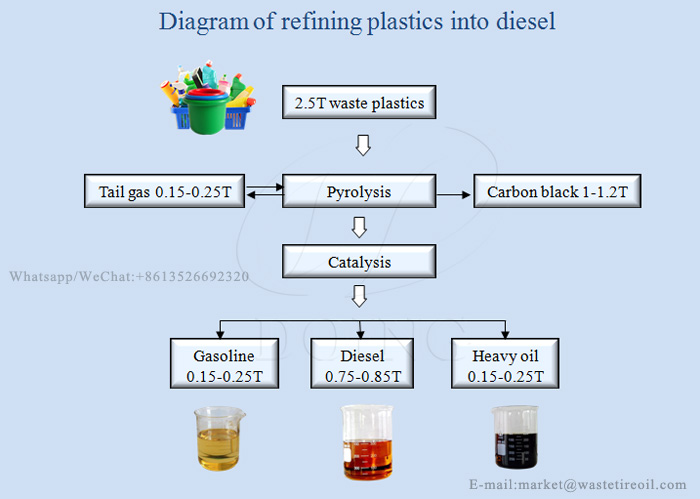

Our waste plastic refining to diesel integrated plant is the integration of waste plastic pyrolysis plant and waste oil distillation plant as well as diesel-gasoline separation, which can produce diesel and gasoline directly from waste plastics and, meanwhile, it is continuous working and fully automatic with PLC control system. Besides, our waste plastic refining to diesel integrated plant is all-in-one machine. For same waste plastic processing capacity, it occupies smaller land area compared with the installation of our waste plastic pyrolysis plant and waste oil distillation plant, so it is very popular with customers who cannot acquire big land and also want to install waste plastic recycling to diesel plant with high automation. Below is the diagram of refining plastics into diesel (Take 2.5 tons of waste plastic as an example).

The diagram of refining plastics into diesel

The diagram of refining plastics into diesel

DOING's integrated plant is equipped with special feeding equipment which is shown in the below picture. Since our waste plastic refining to diesel integrated plant is fully continuous, so it has requirement on the feeding plastics. For example, waste plastics should be as clean as possible without metals or stone mixing inside. Besides, the plastic waste should be dry with humidity <20% and crushed before feeding. If your plastic waste cannot meet the above conditions, you will further need plastic selecting, drying and crushing devices.

Special feeding equipment of waste plastic refining to diesel integrated plant

Special feeding equipment of waste plastic refining to diesel integrated plant

The final product of our waste plastic refining to diesel integrated plant is diesel and gasoline in the proportion of 4:1. You can see about 20% light gasoline is separated from the diesel, therefore the diesel got from our waste plastic refining to diesel integrated plant will have higher flash point than the diesel got from the combination of our waste plastic pyrolysis plant and waste oil distillation plant. If you have requirement on the flash point of final diesel got from waste plastic, this integrated plant will be better choice for you.

The final product of waste plastic refining to diesel integrated plant

The final product of waste plastic refining to diesel integrated plant

However, for same waste plastic processing capacity, our waste plastic refining to diesel integrated plant will be more costly than the combination of waste pyrolysis plant and waste oil distillation plant due to its advantages mentioned above. DOING Company provides different solutions for getting diesel from waste plastic, please send inquiry to get the one most fit for your situation.

PREV:Integrated waste tyre to diesel plant

PREV:Integrated waste tyre to diesel plant

NEXT:Nothing

NEXT:Nothing

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?