Continuous tyre pyrolysis system – Automatic Waste Tyre Recycling Machine

Waste tyres, often dubbed "black pollution," pose significant environmental hazards when improperly disposed of. Traditional disposal methods like burning or landfilling waste tyres not only contribute to pollution but also result in wasted valuable resources. However, DOING, a leading manufacturer of continuous pyrolysis equipment, presents an advanced Continuous Tyre Pyrolysis System, which can transform these discarded tyres into valuable energyproducts like fuel oil, carbon black, and steel wire, offering a sustainable, eco-friendly, and highly profitable recycling solution.

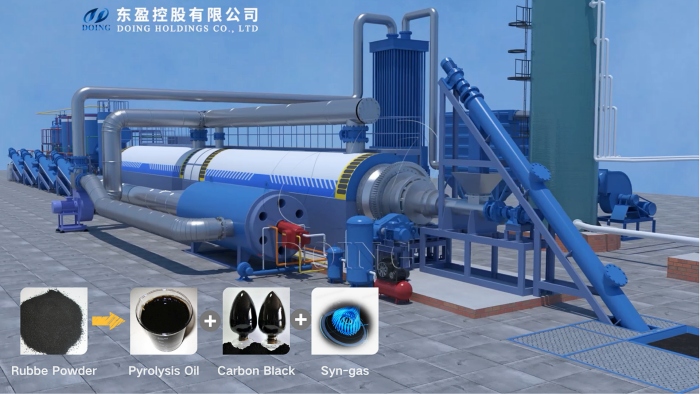

Continuous tyre to oil and carbon black pyrolysis system

Continuous tyre to oil and carbon black pyrolysis system

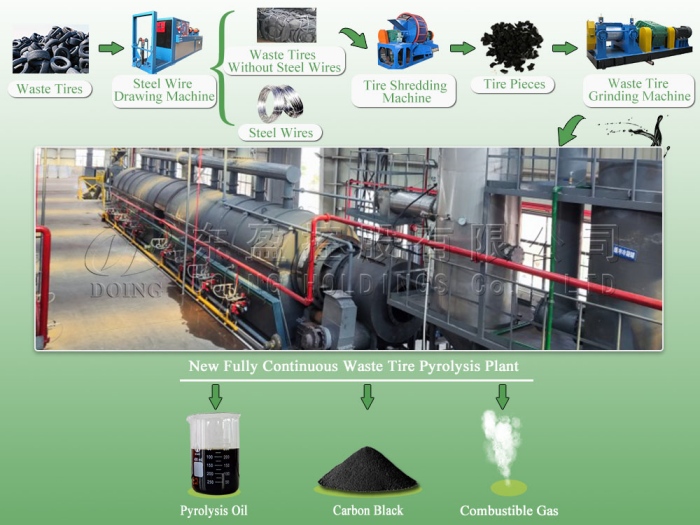

Full Continuous Tyre Pyrolysis Process – From Waste to Wealth

The Continuous Tyre Pyrolysis System supplied by Doing offers an industrial-scale, fully automated waste tyre solution, designed for efficiency and scalability. The entire tyre recycling pyrolysis process operates in a fully continuous manner, and the materials are fed in and cracked without interruption, maximizing throughput and minimizing downtime. Here's how the process works:

Continuous tyre pyrolysis system working process flow

Continuous tyre pyrolysis system working process flow

①Tyre Processing: Waste tyres are shredded into rubber powder before entering the pyrolysis reactor, removing steel wire. The processing machines may include tire shredding machine, steel wire drawing machine, tyre side-wall cutter, tire crushing machine, etc.

②Automated Feeding: and automatically fed into the reactor, ensuring continuous operation without interruptions.

③Pyrolysis : The tyre pyrolysis reactor provides an oxygen-free environment where the tyres undergo thermal decomposition at high temperatures about 280-450°C, breaking down the rubber into oil gas.

④Rapid Condensation: Pyrolysis gases are quickly condensed in advanced condensers into high-quality fuel oil, suitable for industrial applications like boilers and generators.

⑤Carbon Black Recovery: The remaining materials—carbon black are discharged and can be further processed or sold for industrial use.

⑥Emission Control: multiple gas purification system, such as exhuast gas spray system, desulfurization and denitrification tower, dust collection device, etc. ensures that harmful emissions are neutralized, keeping air quality in check and complying with EIA environmental standards.

The fully continuous tyre pyrolysis process maximizes efficiency, reduces operational costs, and increases output—making it a top choice for large-scale tyre recycling projects.

Key Features & Technological Breakthroughs

DOING fully continuous tyre pyrolysis system features

DOING fully continuous tyre pyrolysis system features

DOING continuous tyre pyrolysis system stands out for its comprehensive approach to efficiency, safety, and environmental responsibility.

High Oil Yield: The system recovers 45%–55% fuel oil from waste tyres, which can be utilized in industrial boilers or power plants. The tyre derived fuel(TDF, also called TPO tyre pyrolysis oil), can be refined into diesel for wider applications by pyrolysis oil distillation machine.

Large-Scale Capacity: Options available for 15, 20, 30 and 50 tons per day per set, allowing for scalable production.

Enhanced Condensation System: Equipped with 3-stage condensers and a cooling area of 100 m², the system maximizes fuel oil recovery by increasing the condensation surface area.

Durable Equipment: The system boasts a 5–8 years lifespan, with a 1-year warranty, ensuring long-term operational stability.

Advanced Safety Features: Includes pressure gauges, automatic alarm systems, and emergency shut-off valves, ensuring the safety of operators and preventing accidents.

Eco-Friendly Design: The system ensures minimal environmental impact through advanced emission control technologies, ensuring compliance with global emission regulations.

Industrial-Scale and Smart Design: With a highly automated control system, the continuous tyre pyrolysis plant can be operated with minimal labor, reducing operational costs and increasing productivity. The PLC control system allows for real-time monitoring of all key parameters, including temperature, pressure, and gas flow, ensuring the system operates at peak efficiency.

PLC system of continuous tyre pyrolysis plant

PLC system of continuous tyre pyrolysis plant

Who Should Invest in the Continuous Tyre Pyrolysis System?

·Continous tyre recycling pyrolysis system is ideally suited for:

·Industrial tyre recycling companies looking to scale their operations.

·Waste management facilities aiming to reduce tyre landfill waste.

·Renewable energy producers looking for alternative fuel energy sources, such as brick/cement/glass/china production factories and heavy oil power plants.

·Steel and carbon black manufacturers seeking to incorporate recycled materials.

·Municipal and private enterprises engaged in large-scale tyre recycling projects.

Benefits of Large-Scale Tyre Recycling Projects

The benefits of adopting such a large-scale tyre recycling solution are substantial:

Energy Recovery: Transform waste tyres into high-quality fuel oil, a valuable energy source for industrial boilers, power plants and oil refinery plants.

Resource Reuse: The carbon black and steel wire recovered from tyres can be reused in various industries,such as manufacturing, construction, and automotive production.

Waste Minimization: By recycling tyres, you reduce the need for landfilling and incineration, helping to alleviate the environmental burden of waste disposal.

Profitability: The continuous operation of the system ensures consistent production and revenue from the sale of fuel oil, carbon black, and steel wire.

Proven Experience and Operational Excellence

Henan Doing Company has been at the forefront of the tyre pyrolysis industry for years. We have a wealth of experience in delivering and operating successful continuous tyre pyrolysis system projects worldwide, such as Russia, United States of Amercia, India, China, Brazil, Kazakhstan, etc. We are proud to showcase experienced and mature operational sites.

DOING continuous tyre pyrolysis system operation sites

DOING continuous tyre pyrolysis system operation sites

And here we sincerely invite you to contact us today to learn more about our Continuous Tyre Pyrolysis System and how it can be tailored to transform waste tyres into valuable resources effectively, helping you make great and sustainable benefits.

Continuous tyre pyrolysis system technical data

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-15 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 15T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate, stainless steel | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, recovered carbon black, steel wire | ||||||

Continuous tyre pyrolysis system final product application

Continuous tyre pyrolysis system of Doing can get Fuel oil (45% to 52%) ,Carbon black (30% to 35%) ,steel wire (12%-15%), these product can use widely in industries.Here are wide-ranging industrial applications of tyre pyrolysis products:

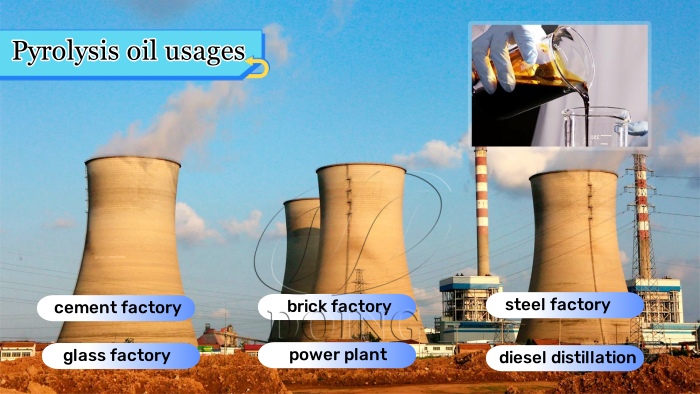

Fuel Oil: Can be used directly in industrial boilers, cement kilns, or further refined into diesel or base oil.

Waste tyre pyrolysis oil industrial applications

Waste tyre pyrolysis oil industrial applications

Carbon Black : An essential ingredient in the manufacturing of new tires, rubber products, plastics, inks, and paints.

Steel Wire: A valuable ferrous metal scrap that can be recycled in steel mills.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?