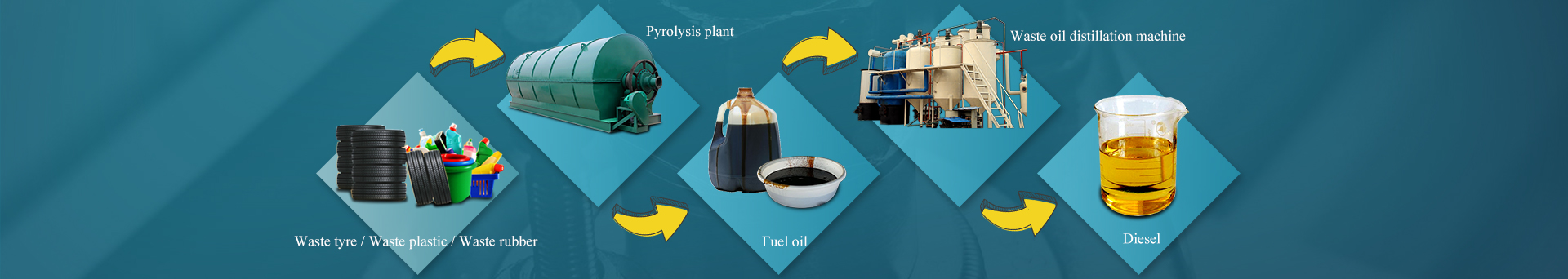

Waste tyre oil to diesel distillation plant

Waste tyre

Waste tyre pyrolysis plant

And the diesel fuel can be used in the low speed engine, such as digging machine, road roller, loading machine and so on. The diesel has higher economic value and higher price in the market, and also can relieve energy crisis.

Waste tyre oil to diesel distillation plant:

Waste tyre oil to diesel distillation plant can convert waste tyre oil, plastic oil, and waste engine oil to diesel. In some country, Waste tyre oil to diesel distillation plant also named waste oil refining machine, distillation equipment, it just name different, but have a same function.

Waste tyre oil to diesel distillation plant not only applied to tyre oil also can use for plastic oil and wste engine oil.

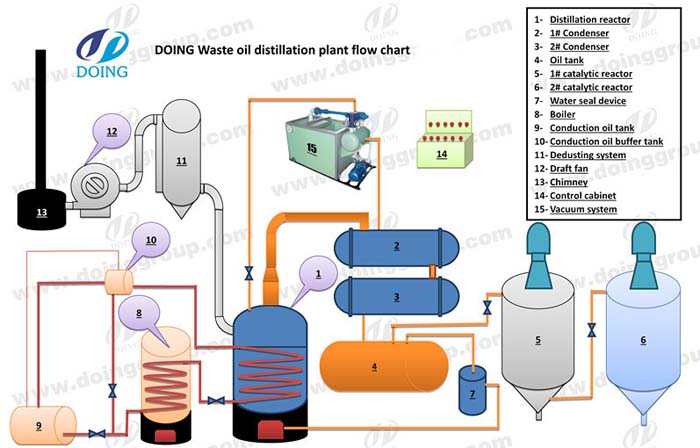

Waste tyre oil to diesel distillation plant working process

2. Heat the reactor, and the liquid oil will slowly become oil gas, oil gas will go through catalytic chamber and condenser, then diesel will be cooled out first by controlling the temperature over 150 Celsius degrees.

3.The gasoline will be cooled out when the temperature is below 150 Celsius degrees, the rest of the system is same as pyrolysis system.

| Technical parameter of waste tyre oil to diesel distillation plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tyre oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

The final diesel oil of waste tyre oil to diesel distillation plant can used for tractors, trucks, ships and generator etc:

Diesel application

After receiving customer’s deposit, we started producing pyrolysis plant, within 30 days can be shipped.

2. Land area and foundation

Pyrolysis plant requires a 30m * 15m of land area; this is only for machines,after delivered this plant, customer can do some preparatory work in accordance with this foundation, or waiting our engineer to do the preparatory work under his guidance.

3. Machine installation

Our company will send one technician for each set of pyrolysis plant for guiding your installation, testing the machine and training your workers.

4. After-sale Service

Warranty of pyrolysis plant and distillation machine is one year. During the year, if not man-made causes of operation, machine failure, or damaged parts, our company will be free of maintenance and replacement parts. However, if the operation because of problems caused by human or machine parts damage, we will not in the warranty.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?