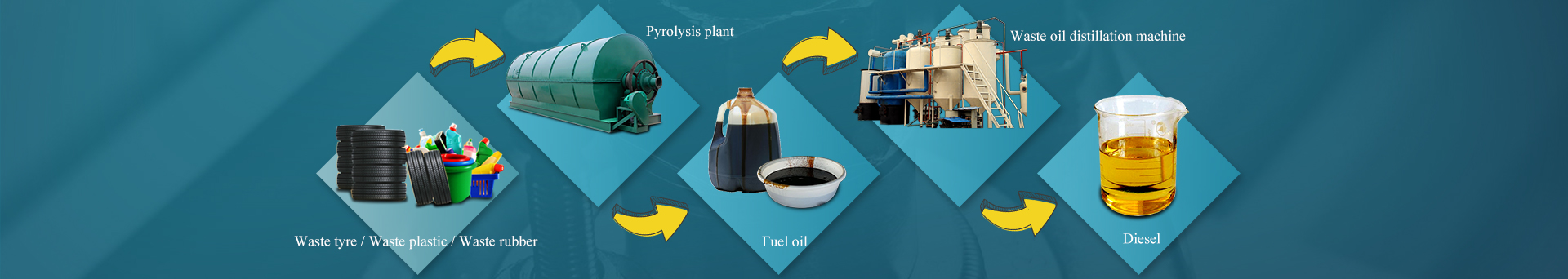

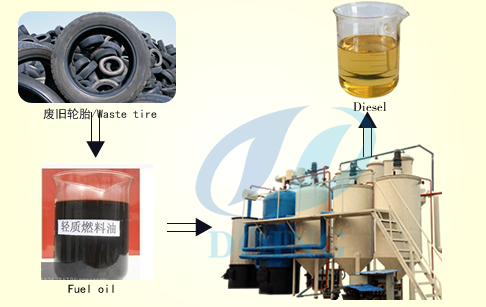

Waste tyre oil to diesel recycling plant

Waste tyre

Waste tyre pyrolysis plant

Waste tyre oil to diesel recycling plant

Waste tyre oil to diesel recycling plant

• During and after the process; no soil, water or air pollution is observed.

• The most cost-effective tire oil to diesel refining plant technology in the world.

• Raw material (waste tyre) is cheap and easy to provide. These are the by-products of tyre production.

• The process can be applied to plastic oil and waste engine oil.

• Vertical structure form, easy for cleaning and maintenance.

• The system creates an alternative source of energy to replace petroleum products and natural gas.

• System gives the opportunity to governments and local administrations to deal with the waste tyre problem to a great extent.

• System prevents the spread of diseases caused by waste tyres oil.

• We deliver plants with capacities of 5 ton to 50t/day and its multiples.

• The process of distillation has duration of 15 to 18 hours, depending on the quality of waste oil. Also it can work day and night. No need to stop.

| Technical parameter of waste tyre oil to diesel recycling plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | waste tyre oil, waste engine oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

| Raw material | output |

| Waste tyre oil | 85%-90% |

| Waste plastic oil | 95% |

| Waste engine oil | 86%-90% |

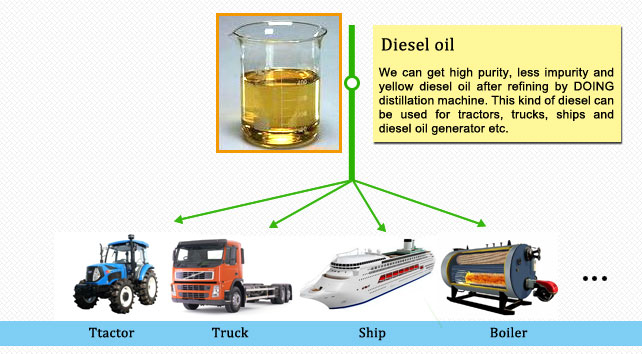

Diesel engines in trucks, trains, boats, and barges help transport nearly all the products people consume. Diesel fuel is commonly used to fuel public buses and school buses.and diesel fuels most of the farm and construction equipment.

The construction industry depends on the power provided by diesel fuel. Diesel are able to do demanding construction work, like lifting steel beams, digging foundations and trenches, drilling wells, paving roads, and moving soil safely and efficiently.

The military uses diesel fuel for tanks and trucks because diesel is less flammable and less explosive than other fuels.

Diesel is also used in diesel engine generators to generate electricity. Many industrial facilities, large buildings, institutional facilities, hospitals, and electric utilities have diesel generators for backup and emergency power supply. Most remote villages use diesel generators for their electricity.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?