Waste tire plastic to fuel pyrolysis process introduction video

Pyrolysis machine is a green waste to energy technology which can recycle waste into fuel. It offers a good solution for waste management and treatment. Here is the pyrolysis machine working process designed by Henan Doing Company as the video shows:

Step one: feeding raw materials

Feed the waste raw materials like waste rubber tire, waste plastic, waste oil sludge, coar tar, aluminum plastic, etc. into pyrolysis reactor.

Step two: heating the reactor for pyrolysis

Keep heating the pyrolysis reactor with burner or other heating fuel, such as coal, wood, pyrolysis oil, syn-gas, LNG, etc. The organic waste will be cracked and oil gas will generate.

Step three: oil gas cooling into liquid pyrolysis oil

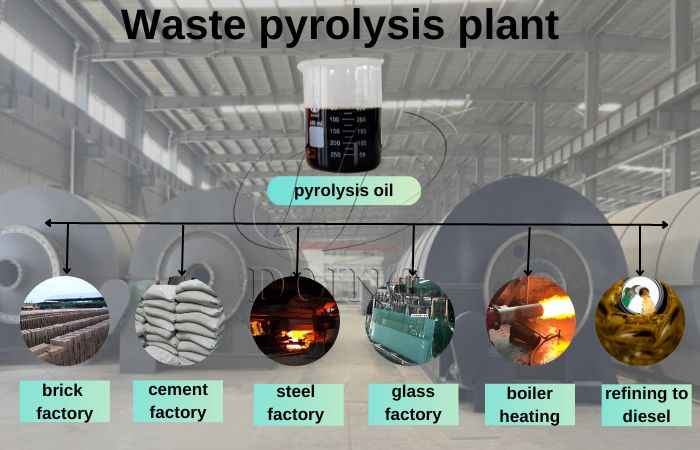

The oil gas will enter the multiple cooling system of DOING pyrolysis machine for condensation. Our cooling system adopts professional industrial multiple-stage condensers which can guarantee the high oil yield. Then you could get liquid pyrolysis oil for sale or heating uses. You can also refine it into diesel fuel by pyrolysis oil distillation plant.

Waste tire plastic pyrolysis oil applications

Waste tire plastic pyrolysis oil applications

Step four: un-condensable gas purification

The exhaust un-condensable gas will be purified by our environmental cleaning system to remove some harmful emissions and the purified gas can be recycled for heating pyrolysis reactor to save investment cost.

Step five: flue gas desulfurization and purification

The flue gas generated in the waste pyrolysis process will be desized and purified by our desulfurization dedusting tower, and then meet the standard emission.

Step six: carbon black and steel wire collection

After the whole pyrolysis process is finished, the pyrolysis machine operator can cool down the pyrolysis reactor and the carbon black can be discharged by wind transfer system. The carbon black can be directly sold, or being briquetted or further refined for industrial production. And then the operator can discharge the steel wire for sale or remelt.

Waste tire plastic to fuel pyrolysis plant projects

Waste tire plastic to fuel pyrolysis plant projects

Henan Doing Company has mature pyrolysis technology including batch pyrolysis technology and continuous type pyrolysis technology. And we have cooperated with thousands of customers to help them customize suitable waste tire plastic to fuel pyrolysis solutions. If you are interested in engaging in related waste pyrolysis business, welcome to contact us for professional guidance.

PREV:Eight sets of oil sludge treatment pyrolysis plants running video in China

PREV:Eight sets of oil sludge treatment pyrolysis plants running video in China

NEXT:14TPD Waste engine oil to Diesel Refining Machine in Indonesia operation video

NEXT:14TPD Waste engine oil to Diesel Refining Machine in Indonesia operation video

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

Delivery of 15TPD plastic to oil pyrolysis machine to India

Delivery of 15TPD plastic to oil pyrolysis machine to India

-

DOING Tire to diesel Pyrolysis & Distillation Plant Shipped to Mexico

DOING Tire to diesel Pyrolysis & Distillation Plant Shipped to Mexico

-

Does plastic pyrolysis process need catalytic chemicals involved?

Does plastic pyrolysis process need catalytic chemicals involved?

-

Colombian Client Invested in DOING 500kg Frame Medical Plastic Waste to Diesel Pyrolysis Distillation Plant

Colombian Client Invested in DOING 500kg Frame Medical Plastic Waste to Diesel Pyrolysis Distillation Plant

-

Indian Client Repurchased DOING 12TPD Batch Tire Pyrolysis Equipment

Indian Client Repurchased DOING 12TPD Batch Tire Pyrolysis Equipment

-

Philippine Client Chose DOING 3 T/D Tire Oil Refining Machine for Market Testing

Philippine Client Chose DOING 3 T/D Tire Oil Refining Machine for Market Testing