DOING 500kg mini pyrolysis unit was shipped to Spain

In May, 2025, the 500kg mini pyrolysis unit provided by Henan DOING for Spanish customers was completed and officially shipped to the customer site. This min pyrolysis unit, which is specially developed for small-scale pyrolysis projects and laboratory scenarios, has both compact design and high-efficiency performance. Here is shipping video:

The mini pyrolysis unit shipped by DOING to Spain this time adopts an integrated frame design, which precisely integrates core modules such as pyrolysis reactors, condensing devices, tail gas purification devices, slag discharge devices and intelligent control unit in a compact space, and the floor space is greatly reduced compared to traditional pyrolysis unit.

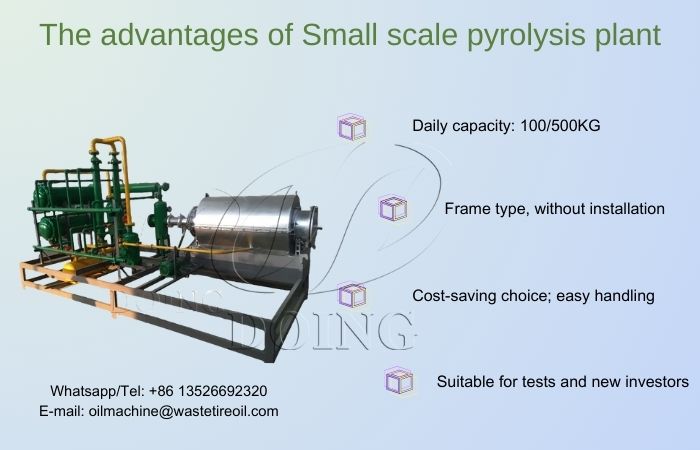

DOING mini pyrolysis unit advantages

DOING mini pyrolysis unit advantages

In addition to the space advantage, the installation and operation convenience of this mini pyrolysis unit are also eye-catching. All main components have been pre-connected and debugged before leaving the factory. After receiving the unit, Spanish customers only need to simply locate it on the ground, connect water and electricity, and quickly start the machine through the operation manual and remote technical guidance. There is no need for complex infrastructure or professional team support, and people who are not very familiar with technology can also quickly get started.

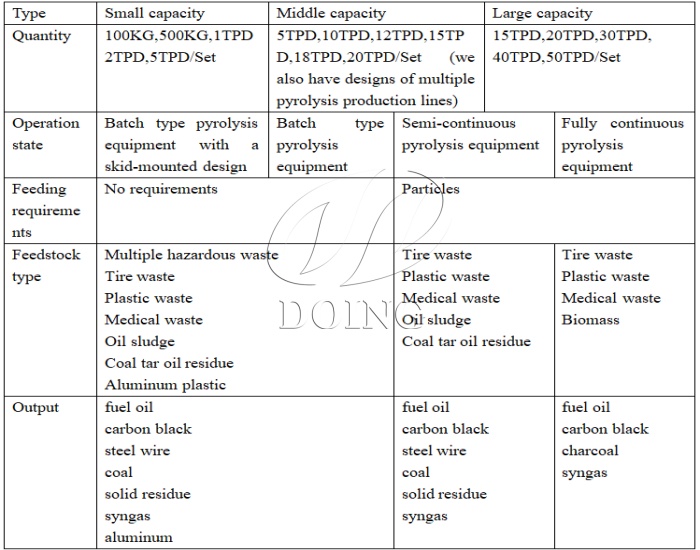

DOING waste pyrolysis machine types

DOING waste pyrolysis machine types

DOING has always been committed to technological innovation. DOING mini pyrolysis unit is particularly suitable for laboratory tests with limited space, initial construction of small-scale refineries or pilot projects in remote areas. Whether it is a university scientific research team conducting fuel oil pyrolysis process research or small and medium-sized enterprises conducting raw material oil yield testing, it can flexibly adapt to various scenarios, so that pyrolysis is no longer limited by the scale of the site. DOING not only provides this small scale mini pyrolysis unit, but also provides large scale batch type, semi-continuous type, fully continuous type pyrolysis equipment. Any customer interested in pyrolysis unit is welcome to consult us. We provide you with a full-process solution from process design, unit manufacturing, to installation and commissioning.

PREV:Shipment of DOING 30 tons of waste oil recycling refinery machine to Kazakhstan

PREV:Shipment of DOING 30 tons of waste oil recycling refinery machine to Kazakhstan

NEXT:A Zambian customer purchased a set of DOING new catalyst distillation machine

NEXT:A Zambian customer purchased a set of DOING new catalyst distillation machine

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

2 Sets of DOING Pyrolysis Equipment for Plastic and Biomass Recycling Installed in China

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand