Used engine oil refining into diesel oil equipment

Used engine oil

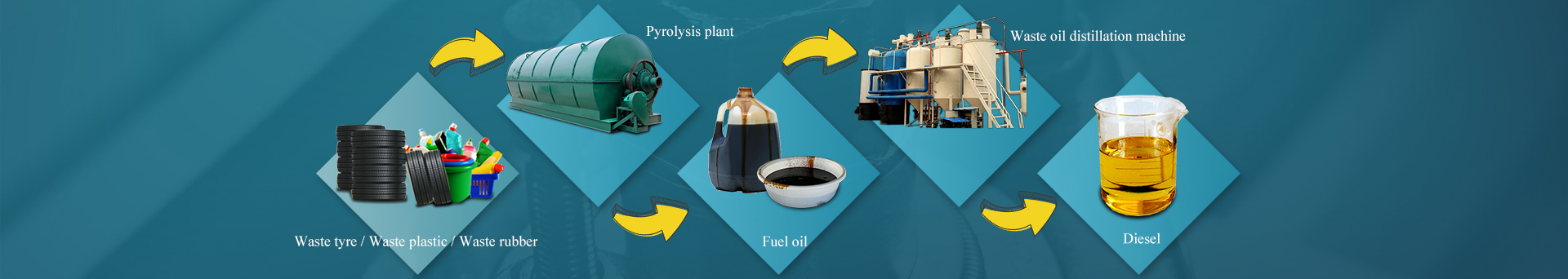

Used engine oil refining into diesel oil equipment working process

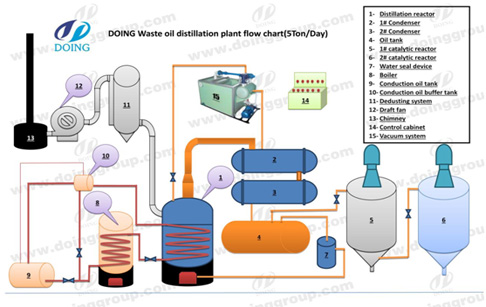

The main working flow of DoingGroup's used engine oil refining into diesel oil equipment is as follows:

1. Pour the heat transfer oil into the heat transfer system and heat the base. The heat conduction system is mainly to preheat the system.

2. High temperature distillation of the base of the reactor to separate some of the residue from the heavy oil. The resulting light oil and gas will enter the next system.

3. Light oil and gas will be liquefied through the condensing system and flow into the tank.

4. The liquefied light oil obtained is subjected to a degreasing and desulfurization treatment, and finally, a clean and transparent non-standard diesel oil is obtained.

Used engine oil refining into diesel oil equipment

1. The reactor adopts a vertical design, which is easier to discharge than a horizontal design.

2. Double heating system, both base heating and heat conduction system, can achieve rapid heating, shorten the heating time, improve the equipment operating efficiency.

3. The number of reactors can be added according to the user's throughput. The capacity of each reactor is 5 tons. If you need to handle 10 tons, you can add a reactor and so on.

| Technical parameter of used engine oil refining into diesel oil equipment | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

After many successful cases, it has been proved that the used engine oil refining into diesel oil equipment has a very broad market. This is because waste oil refining equipment can obtain non-standard diesel oil and asphalt. In particular, non-standard diesel oil has a very important role in our lives. Of course, this is also the main source of profit for this equipment:

Diesel oil usage

2. Asphalt: Mainly used for paving and asphalt plant refining.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?