Waste engine oil to diesel distillation machine

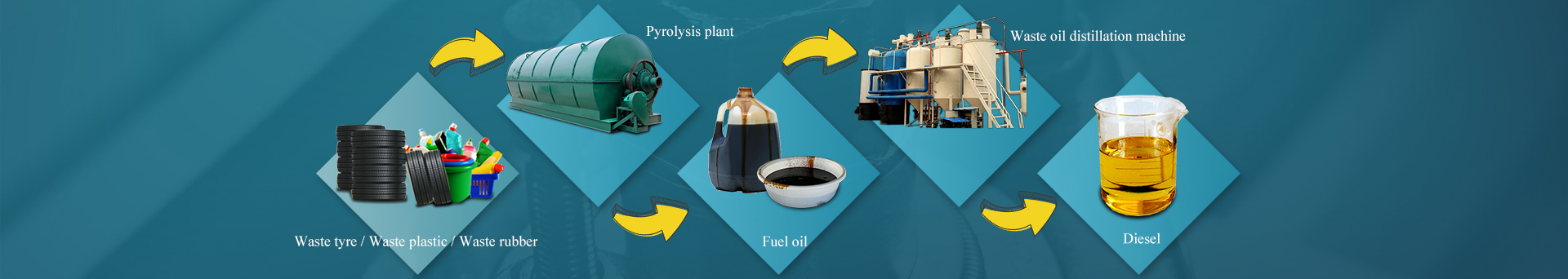

Waste engine oil to diesel distillation machine can extract diesel from waste engine oil. This machine can not only solve the problem of environmental pollution caused by waste engine oil, but also realize the recovery and reuse of waste engine oil. In fact, some discerning customers have been able to make huge profits from the waste engine oil to diesel distillation machine. Next, I will mainly introduce the work flow and advantages of waste engine oil to diesel distillation machine, and how this machine can be highly profitable.

Waste engine oil to diesel distillation machine can convert waste engine oil into diesel

Waste engine oil to diesel distillation machine can convert waste engine oil into diesel

With the extensive use of automobiles and ships, a large amount of engine oil is replaced every year around the world. Most of the waste engine oil after replacement is dumped or burned on site, which not only wastes a lot of resources, but also causes serious environmental pollution.

Waste engine oil

Waste engine oil

In order to promote the development and utilization of energy, improve the energy structure and protect the environment, the research and development team of DOING company developed waste engine oil to diesel distillation machine.

Waste engine oil to diesel distillation machine

Waste engine oil to diesel distillation machine

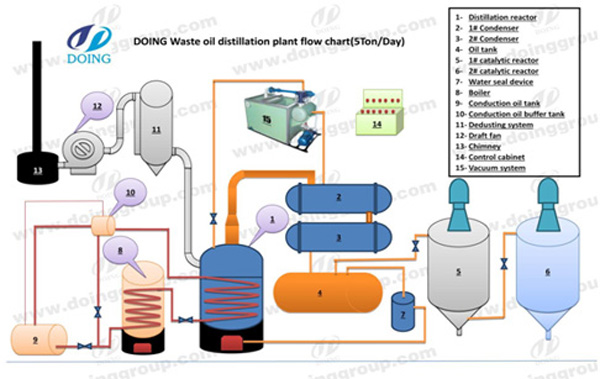

The main work flow of waste engine oil to diesel distillation machine is as follows:

1. Heat the heat conduction oil with the heat conduction oil furnace;

2. The heat conducting oil flows into the coil in the distillation reactor and heats the waste engine oil in the distillation reactor;

3. When the waste engine oil is heated to a certain temperature, the reactor is directly heated with fuel. As the temperature increases, the waste engine oil produces oil and flows into the buffer tank. The odorous light components in the waste engine oil can be distilled and collected into the distillation tank.

4.The oil gas from the buffer tank enters the catalytic tower. In the catalytic tower the macromolecular oil gas are broken down into smaller molecules.

5. Oil gas of small molecules enter the cooling system through the catalytic tower and are cooled into liquid oil; 6. After the oil gas steam out, the distillation reactor memory has plenty of hot asphalt, can be extracted by the asphalt pump.

The main work flow of waste engine oil to diesel distillation machine

The main work flow of waste engine oil to diesel distillation machine

The main advantages of waste engine oil to diesel distillation machine are as follows:

1. The distillation reactor adopts vertical design, which is more conducive to improving the oil conversion rate.

2. Waste engine oil to diesel distillation machine adopts double heating system. The double heating system has the advantages of fast heating speed and high efficiency, which can save customers' time.

3. The waste engine oil disposal process of waste engine oil to diesel distillation machine will not produce any pollution to the environment.

Waste engine oil to diesel distillation machine technical parameter

| Technical parameter of waste oil refining diesel oil machine | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

The final products from waste engine oil to diesel distillation machine are mainly diesel oil and asphalt.

The main USES are as follows.

1. Diesel oil: Mainly used for heavy machinery, generators, boilers, tractor, ship, truck, etc.

Usage of diesel

Usage of diesel

2. Asphalt: Mainly used for paving or sent to asphalt plants for re-refining.

There are places where you can get used oil for free, but the diesel and asphalt obtained from the waste engine oil can be sold at a very good price, so if you work on the waste engine oil to diesel project, you can make a big profit.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?