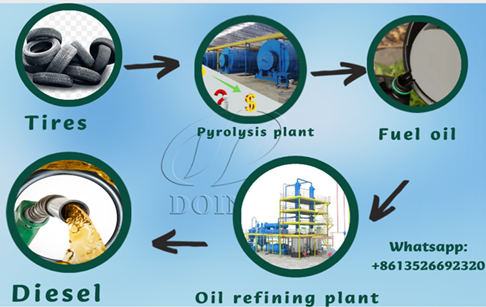

Tire Plastic Pyrolysis Oil to Diesel Refinery Plant

Tire plastic pyrolysis oil to diesel refinery plant, just as its name implies, it’s a technical plant that is able to refine the tire or plastic pyrolysis oil into diesel. How does it happen? Henan DOING Group company, professional manufacturer of waste pyrolysis plants and oil refinery plants with 11+ years experience, will give you full information about the refinery plant.

Brief introduction

Henan DOING Tire Plastic Pyrolysis Oil to Diesel refinery plant is specifically designed for refining tire plastic pyrolysis oil to light diesel. And it can also be used to dispose and recycle the waste oil like used engine oil, lube oil, waste car/motor oil, etc. into diesel. The Pyrolysis Oil to Diesel oil yield is as high as 85%.

Working process

This whole refining process of tire plastic pyrolysis oil to diesel includes distillation, cooling, decoloring and deordoring. And here is the 3D animation video of tire plastic pyrolysis oil to diesel refining process.

New design tyre pyrolysis oil to diesel processing video

1. Distillation processing--Pumping the tire plastic oil into the distillation reactor by an oil pump and preheating the distillation reactor with a burner. During distillation processing, the oil gas will come out slowly until all oil is distilled from tire plastic oil under vacuum production environment. The slag will be left on the bottom of the reactor.

2. Cooling system--Adapting professional industrial condensers which assure the oil gas will be cooled into liquid diesel directly into temporary tanks after catalyst affection, at the same time, it improves the oil yield as well.

3. Decoloring system--Getting the diesel color much lighter on base of some special catalyst affection, as much as close to the standard diesel color.

4. Deodering system--With deodoring devices, it can dispose and remove the unpleasant smell of the diesel.

Advantages of DOING tire plastic pyrolysis oil to diesel refinery plant:

1. Using the fast heating system, the refining process is efficient, the time required is shorter, and fuel is saved at the same time.

2. The distillation reactor of the refinery plant adopts the vertical design, which can realize automatic slag discharge, which is convenient and fast.

3. The cooling mode is water cycle cooling, and the water is recycled with almost no consumption.

4. The tire plastic pyrolysis oil to diesel refinery plant adopts professional diesel oil purification systems, and the distilled diesel is of good quality and high quality.

Parameters

And to meet different customers' refining needs, we can customize different scales of tire plastic pyrolysis oil to diesel refinery plants based on the situation. Below is the parameter information for your checking. For more information and free quotes, please feel free to contact us.

Pyrolysis oil to diesel plant technical parameter| Technical parameter of pyrolysis oil to diesel plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-30t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

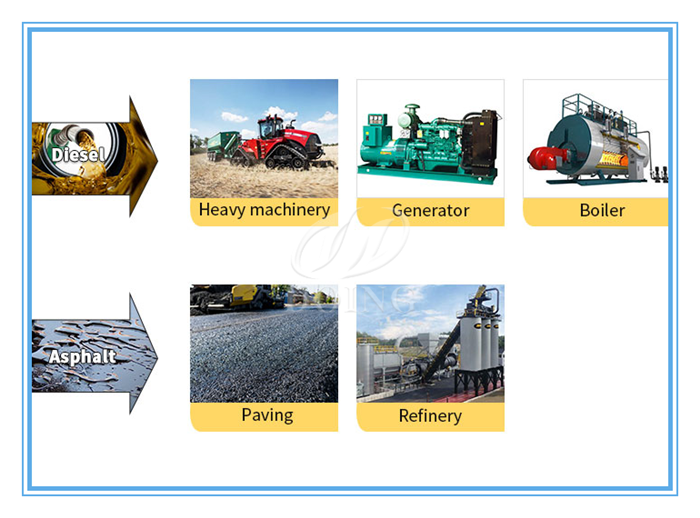

Final products and applications

Two final products will be obtained from DOING tire plastic pyrolysis oil to diesel refinery plant after these refining process, diesel and asphalt. The final diesel product could be used as alternative fuel in diesel burners, generators, heavy machinery and agricultural machinery, etc. And the residuals will be asphalt which is mainly used for paving the road or selling asphalt to factories directly for further refinery.

The final diesel product and application

The final diesel product and application

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?