How do you filter used motor oil and make diesel fuel?

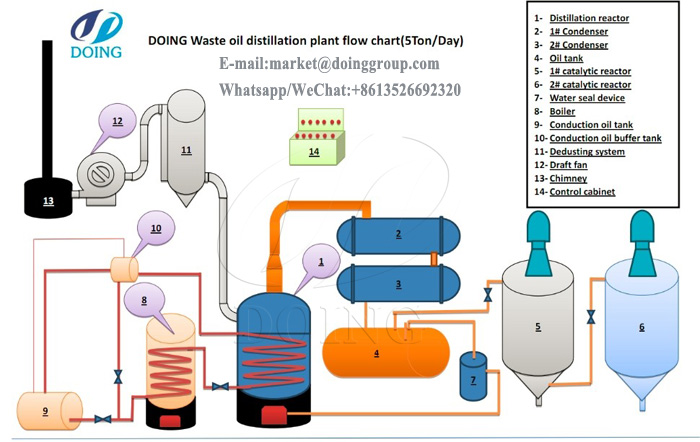

With the mature application of distillation technology, now we can use the distillation plant to filter used motor oil and make diesel fuel. The project of filtering used motor oil to make diesel fuel can reduce used motor oil pollution and reuse used motor oil. It has great practical significance in life. Below is the picture of this used motor oil distillation plant. It can filter used motor oil and make diesel in the following four steps.

Used motor oil distillation plant

Used motor oil distillation plant

The main process of filtering used motor oil and make diesel fuel by used motor oil distillation plant

Step 1 Feeding

Collect used motor oil in an oil tank and put into distillation reactor. After filling the distillation reactor, close the oil inlet. Turn on the heating device to start heating distillation reactor. At the same time, the condensation system is opened and the flue gas draught system, the distillation process is started.

Step 2 Heating

By controlling the burner, the used motor oil in the reactor is cracked until the temperature more than 300 degrees Celsius. When all the used motor oil gas is distilled from the used motor oil, stop heating. This process needs to observe the thermometer and pressure valve, and adjust the temperature control according to the on-site conditions. It usually takes about 10-12 hours. For these processes, our engineer will specifically train workers to operate the machine.

Step 3 Cooling

The resulting oil gas will be cooled by a condensing system. Our distillation plant adopt column condensation, which condensation effect is good, and can improve the oil conversion rate.

Step 4 Collecting

After step of heating and cooling process, the light diesel fuel in the used motor oil will be stored in the oil tank. The oil pump can be turned on and the diesel fuel in the oil tank can be pumped out and transported to a large oil tank for storage.

The main process of filtering used motor oil by distillation plant

The main process of filtering used motor oil by distillation plant

Through the above steps, the oil will be distilled out. All that is left in the distillation reactor is oil residue.The residue in reactor bottom could be pumped out. At this point, the whole process to filter used motor oil and make diesel fuel is basically over. And you could ready to run the second process.

Using this used motor oil distillation plant to filter used motor oil and make diesel fuel is efficient, safe, and the oil conversion rate is high. Used motor oil distillation plant can also be used in large-scale production. It has been favored by many investors. If you are interested in this way of filtering used motor oil and make diesel fuel, please contact us. Our engineers will contact you within 24 hours.

PREV:How to clean used motor oil for fuel?

PREV:How to clean used motor oil for fuel?

NEXT:How much does it cost to build a waste motor oil refinery plant in Nigeria?

NEXT:How much does it cost to build a waste motor oil refinery plant in Nigeria?

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia

-

15 TPD used tyre pyrolysis machine produced fuel oil in Brazil